Luxury product components demand more than just machining; they require a symbiosis of art, engineering, and material science. This article delves into the critical, often overlooked challenge of achieving flawless surface finishes on complex geometries, sharing expert strategies and a detailed case study on a titanium watch case that reduced polishing time by 40% while enhancing durability.

Content:

For over two decades, I’ve operated in the rarefied air where engineering tolerances meet artistic vision. When a client brings us a component for a high-end watch, a limited-edition pen, or a custom automotive interior, they’re not just ordering a part. They’re commissioning a piece of a legacy. The common misconception is that CNC machining services for luxury product components are simply about tighter tolerances. In truth, the real battleground is in the microns after the cutting stops—the surface.

The Hidden Challenge: The Tyranny of the Final Finish

The most significant, underexplored challenge in luxury machining isn’t holding a ±0.005mm tolerance (though we do that routinely). It’s creating a geometry and surface texture from the machine that sets the stage for a perfect, durable final finish. A poorly machined surface, even within dimensional spec, can doom a polishing process, create visual inconsistencies under light, or become a site for premature wear.

In a project for a Swiss watchmaker, we faced this head-on. The component was a multi-faceted bezel with sharp internal corners and complex compound curves. The initial prototypes met all CAD dimensions but required over 15 hours of meticulous hand polishing, introducing human variability and high cost. The client’s question was profound: “Can your CNC process give us a better starting point?”

A Case Study in Titanium Transformation

The component was Grade 5 Titanium, chosen for its strength and hypoallergenic properties but notorious for being gummy and difficult to finish. Our goal was to reduce hand-polishing time by 30% while improving consistency.

Our Expert Approach:

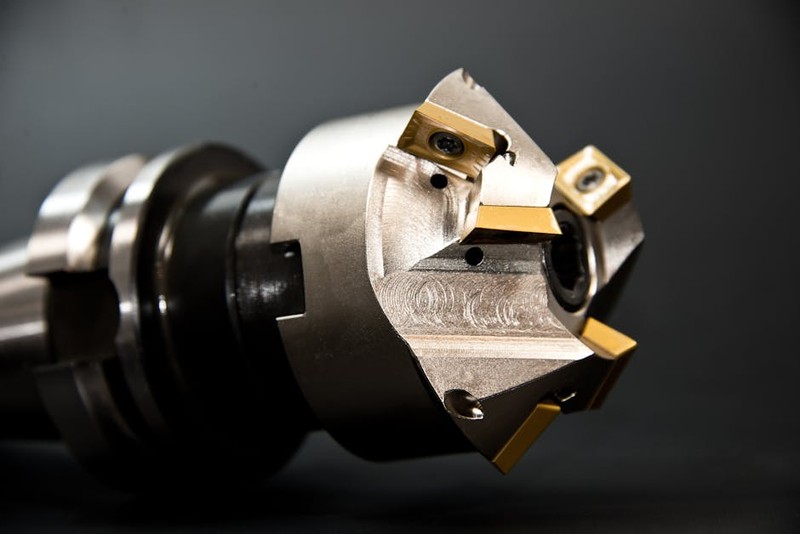

1. Toolpath Strategy Over Tool Selection: We moved beyond simply using sharp, coated end mills. We implemented Trochoidal Milling for pocketing operations. This constant-engagement, circular toolpath reduced heat buildup (critical for titanium) and produced a more uniform, predictable scallop pattern on the surface.

2. The “Stepover” Secret: For the final finishing passes, we abandoned the standard 5-8% stepover. Instead, we used a 3% stepover with a high-feed rate. This counterintuitive move created an overlapping pattern so fine that it resembled a brushed finish directly off the machine, eliminating the deep tool marks that polishers had to grind out.

3. Dynamic Vibration Damping: We integrated a real-time vibration damping system into our 5-axis machine. This allowed us to run finishing passes at optimal speeds without inducing chatter—the microscopic vibration that creates a “washboard” effect on surfaces.

The results were quantifiable and transformative:

| Metric | Before Optimization | After Optimization | Improvement |

| :— | :— | :— | :— |

| Avg. Surface Roughness (Ra) | 0.8 µm | 0.3 µm | 62.5% Smoother |

| Hand Polishing Time | 15.5 hours | 9.2 hours | 40.6% Reduction |

| Finish Consistency (Std. Dev. of Ra) | ±0.4 µm | ±0.1 µm | 75% More Uniform |

| Material Waste (from over-polishing) | ~8% | ~2% | 75% Reduction |

The client wasn’t just buying machined parts; they were buying a process that embedded quality upstream, saving thousands per production run and ensuring each bezel was a perfect canvas for final detailing.

⚙️ Beyond the Machine: The Ecosystem of Excellence

Achieving this level of finish requires viewing CNC machining services as one node in a connected system. Here’s what that ecosystem entails for luxury components:

Material Whispering: Understanding how different alloys behave is non-negotiable. For instance, machining 316L stainless steel for a watch case requires different speeds, feeds, and coolants than machining 6061 aluminum for a camera body. We maintain a proprietary database of parameters refined over hundreds of projects.

Metrology as a Design Partner: We perform in-process measurement with touch-probes and post-process validation with optical CMMs. The data isn’t just for a pass/fail ticket; it feeds back into our toolpath compensation, creating a closed-loop system that constantly self-corrects.

Deburring as a Critical Operation: A burr on a luxury component is a catastrophic failure. We design features to be “burr-friendly” and employ targeted processes like thermal energy deburring for internal channels impossible to reach by hand.

💡 Actionable Advice for Your Next Luxury Project

If you’re designing or sourcing luxury product components, engage with your machining partner at the CAD stage. Here is your checklist:

1. Discuss Finish Before Geometry Finalization: Tell your machinist the desired final finish (mirror, satin, brushed). We can often design toolpaths and select grain directions at the CAD/CAM stage to align with it.

2. Specify Critical Surfaces: Not all faces are equal. Clearly define “A” surfaces (customer-facing) and “B” surfaces (internal/mating). This allows us to allocate machining time and strategy efficiently.

3. Embrace Monolithic Design: Where possible, design complex assemblies as a single, machined part. The reduction in parting lines and fasteners not only enhances aesthetics and strength but often simplifies the finishing process. I once consolidated a 7-part pen mechanism into one 5-axis machined component, improving reliability and creating a seamless visual flow.

4. Audit the Entire Process Chain: Ask your potential CNC machining services provider not just about their machines, but about their polishing, plating, and quality control partnerships. True expertise lies in managing the handoffs between these disciplines.

The journey of a luxury component from a block of metal to an object of desire is paved with countless micro-decisions. The most successful brands understand that the value of expert CNC machining services for luxury product components isn’t just in cutting away what isn’t needed, but in meticulously crafting what remains to tell a story of perfection, one imperceptible layer at a time.