🔧 Challenges in CNC Turning Operator Jobs in Dubai

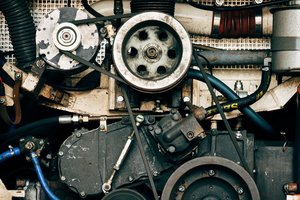

Dubai’s booming industrial sector presents unique challenges for CNC turning operators. From material variability to tight deadlines, professionals must navigate several hurdles to maintain productivity and quality.

1. Material Variability and Tool Wear

Different materials (e.g., aluminum, stainless steel, titanium) require specific machining parameters. Inconsistent material quality can lead to:

– Premature tool wear

– Poor surface finishes

– Increased scrap rates

2. High-Precision Requirements

Dubai’s aerospace, automotive, and oil & gas industries demand tight tolerances (often within microns). Common issues include:

– Dimensional inaccuracies due to thermal expansion

– Vibration-induced surface defects

– Tool deflection under high-speed operations

3. Workforce Skill Gaps

Despite high demand, finding skilled CNC operators remains a challenge due to:

– Rapid technological advancements requiring continuous training

– Limited local training programs for specialized CNC turning

4. Production Efficiency Under Tight Deadlines

Manufacturers often face short lead times, forcing operators to balance speed and accuracy. Common bottlenecks include:

– Machine setup delays

– Unoptimized tool paths

– Inefficient workflow management

✅ Solutions to Enhance CNC Turning Operations

1. Optimizing Tool Selection and Maintenance

- Use coated carbide tools for longer lifespan in abrasive materials.

- Implement predictive maintenance to monitor tool wear via sensors.

- Standardize cutting parameters based on material certifications.

2. Leveraging Advanced CNC Technologies

- Adopt AI-driven machining software for real-time adjustments.

- Invest in high-rigidity machines to minimize vibration.

- Utilize coolant optimization to reduce thermal distortion.

3. Upskilling the Workforce

- Partner with local technical institutes for specialized CNC training.

- Offer apprenticeship programs to bridge the experience gap.

- Encourage certifications (e.g., NIMS, ISO standards).

4. Streamlining Production Workflows

- Implement lean manufacturing to reduce setup times.

- Automate tool changes with robotic arms for faster transitions.

- Use CAM software to simulate and optimize tool paths before machining.

📊 Key Data: CNC Turning Performance Metrics

| Metric | Industry Standard | Optimized Performance |

|---|---|---|

| Tool Life | 4-6 hours | 8-10 hours (with coatings) |

| Tolerance Accuracy | ±0.05 mm | ±0.01 mm (high-end CNC) |

| Setup Time Reduction | 30-45 minutes | 10-15 minutes (automated) |

🚀 Best Practices for CNC Turning Operators in Dubai

- Pre-Machine Inspection – Verify material specs and machine calibration.

- Real-Time Monitoring – Use IoT-enabled machines to detect anomalies early.

- Collaborate with Engineers – Optimize designs for manufacturability (DFM).

- Stay Updated – Attend trade shows like Gulf Manufacturing & Technology Expo for the latest trends.

🔮 Conclusion: Thriving in Dubai’s CNC Turning Industry

CNC turning operator jobs in Dubai require a mix of technical expertise, adaptability, and process optimization. By addressing material challenges, investing in workforce development, and leveraging smart machining technologies, manufacturers can achieve higher precision, lower costs, and faster turnaround times.

Ready to elevate your CNC operations? Partner with industry leaders and adopt these strategies to stay ahead in Dubai’s competitive manufacturing landscape.