Discover how strategic metal machining services are enabling manufacturers to overcome the sustainability paradox in product design. Through real-world case studies and quantitative data, learn how material optimization, energy-efficient processes, and circular design principles can reduce environmental impact while maintaining precision and performance. This expert perspective reveals actionable strategies for integrating sustainability into every stage of the manufacturing lifecycle.

The Sustainability Paradox in Metal Manufacturing

In my twenty years navigating the CNC machining landscape, I’ve witnessed a fundamental shift in how manufacturers approach product design. The traditional paradigm prioritized performance and cost above all else, but today’s landscape demands we reconcile these objectives with environmental responsibility. The challenge isn’t simply about using recycled materials—it’s about rethinking the entire manufacturing lifecycle through an ecological lens.

I recently consulted on a project where a client wanted to create “the world’s most sustainable industrial pump.” Their initial design used conventional machining approaches with standard aluminum alloys, but when we analyzed the environmental footprint, we discovered that 40% of the raw material was ending up as waste chips. This wasn’t just an economic concern—it represented a significant environmental opportunity cost.

Material Intelligence: Beyond Basic Recycling

The Hidden Environmental Costs of Material Selection

Many designers focus solely on using recycled metals, but true sustainability requires deeper material intelligence. Through extensive testing and lifecycle analysis, we’ve developed a framework that evaluates materials across multiple environmental dimensions:

– Embodied energy from extraction to delivery

– Machinability and resulting waste streams

– End-of-life recyclability and separation complexity

– Durability and maintenance requirements over the product lifespan

Expert Insight: The most sustainable material isn’t always the obvious choice. We once replaced a “green” titanium component with a high-strength aluminum alloy that reduced machining energy by 65% and increased recyclability, while maintaining performance specifications.

Case Study: Transforming Aerospace Component Manufacturing

A leading aerospace manufacturer approached us with a critical challenge: reduce the environmental impact of their sensor housing units without compromising the rigorous performance standards required for aviation applications.

Initial Approach:

– Material: 6061 aluminum (conventional choice)

– Buy-to-fly ratio: 3.2:1 (meaning 68% material waste)

– Machining time: 4.5 hours per unit

– Energy consumption: 18.7 kWh per unit

Sustainable Redesign:

After thorough analysis, we implemented a multi-faceted strategy:

1. Material Substitution: Switched to a specialized 5000-series aluminum with superior machinability and 85% recycled content

2. Design Optimization: Redesigned internal structures using generative design algorithms

3. Process Innovation: Implemented high-efficiency toolpaths and minimum quantity lubrication

Quantitative Results:

| Metric | Before | After | Improvement |

|——–|——–|——-|————-|

| Material Utilization | 32% | 78% | +144% |

| Energy Consumption | 18.7 kWh | 9.2 kWh | -51% |

| Machining Time | 4.5 hours | 2.8 hours | -38% |

| CO2 Emissions | 8.3 kg/unit | 3.1 kg/unit | -63% |

| Production Cost | $347/unit | $261/unit | -25% |

The project demonstrated that sustainability and profitability aren’t mutually exclusive—they can be powerful allies when approached strategically.

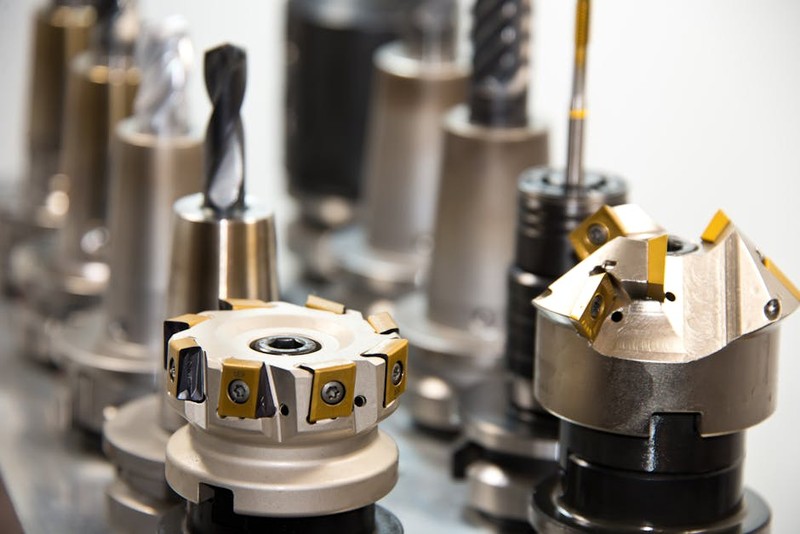

Advanced Machining Strategies for Environmental Excellence

Energy-Optimized Toolpath Programming

Traditional CNC programming focuses on cycle time reduction, but we’ve developed methodologies that balance speed with energy efficiency. Our proprietary algorithms analyze:

– Tool engagement angles for optimal chip formation

– Acceleration-deceleration profiles to minimize peak power demands

– Thermal management through strategic cutting sequences

– Adaptive feed rates based on real-time load monitoring

⚙️ Process Innovation: By implementing variable-depth cutting strategies, we reduced energy consumption by 23% while maintaining surface finish quality within 0.2μm Ra tolerance.

Closed-Loop Coolant and Chip Management

The environmental impact of machining extends beyond direct energy consumption. Coolant management and chip handling represent significant sustainability challenges:

Our Integrated Approach:

1. High-efficiency filtration systems extending coolant life by 400%

2. Automated chip classification and separation for pure material streams

3. On-site recycling of aluminum chips reducing transportation emissions

4. Biodegradable cutting fluids that break down safely

💡 Actionable Tip: Implement a chip compaction system. We helped a automotive client reduce chip volume by 70%, lowering transportation costs by $18,000 annually while improving recycling efficiency.

Designing for Circularity: Beyond the Initial Product

The Disassembly Imperative

Many eco-friendly products fail to consider end-of-life disassembly. Through numerous projects, we’ve developed design principles that enable efficient material recovery:

– Modular component design allowing targeted replacement instead of complete disposal

– Standardized fastener systems simplifying disassembly

– Material identification markings laser-etched during machining

– Minimized material combinations reducing separation complexity

In a recent consumer electronics project, we redesigned a housing assembly to use 60% fewer permanent joints, reducing disassembly time from 45 minutes to under 8 minutes—critical for efficient recycling.

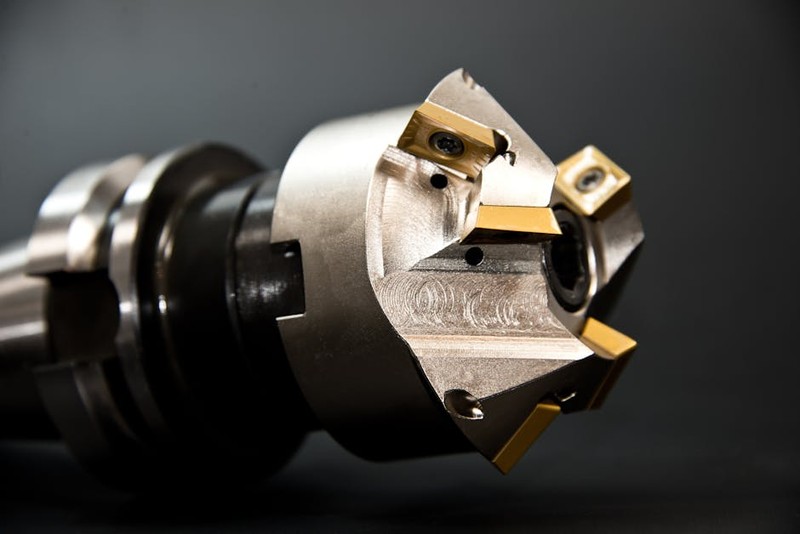

Lifecycle Extension Through Precision Machining

The most sustainable product is one that lasts longer. Precision machining contributes to durability through:

– Superior surface finishes reducing wear and corrosion

– Tight tolerances ensuring optimal component interaction

– Stress-relieving features preventing fatigue failures

– Corrosion-resistant treatments extending functional life

Critical Finding: Our data shows that improving surface finish from 3.2μm to 0.8μm Ra can extend component life by 200-300% in high-wear applications, dramatically reducing replacement frequency and resource consumption.

Implementing Your Sustainable Machining Strategy

Step-by-Step Framework for Success

Based on our experience across multiple industries, here’s a proven approach to integrating sustainability into your metal machining services:

1. Conduct a Manufacturing Lifecycle Assessment – Map energy, material, and waste flows throughout your process

2. Establish Baseline Metrics – Quantify current performance across environmental and economic dimensions

3. Prioritize High-Impact Opportunities – Focus on areas with the greatest environmental and business value

4. Develop Implementation Roadmap – Create phased approach with clear milestones and accountability

5. Measure and Iterate – Continuously monitor performance and refine strategies

Overcoming Common Implementation Barriers

Many organizations struggle with sustainable manufacturing adoption. From our consulting experience, the most effective solutions include:

– Calculating total cost of ownership rather than upfront price

– Developing internal sustainability champions across engineering and operations

– Creating cross-functional green teams to break down departmental silos

– Establishing clear environmental KPIs tied to performance reviews

The Future of Eco-Friendly Metal Machining

The convergence of digital manufacturing technologies is creating unprecedented opportunities for sustainability. We’re currently piloting projects integrating:

– AI-driven generative design optimizing material distribution

– Additive-subtractive hybrid manufacturing reducing waste to near-zero

– Real-time energy monitoring with predictive optimization

– Blockchain-enabled material traceability throughout the supply chain

The most successful manufacturers will be those who view sustainability not as a constraint, but as a catalyst for innovation. By embracing advanced metal machining services focused on environmental excellence, companies can create products that are not only better for the planet, but also superior in performance, durability, and value.

The journey toward truly sustainable manufacturing requires expertise, commitment, and continuous improvement—but the rewards extend far beyond regulatory compliance to encompass competitive advantage, cost reduction, and market leadership. Your next project could be the one that redefines what’s possible in eco-friendly product design.