The Hidden Challenge: When “Green” Design Meets Manufacturing Reality

In my two decades of running a precision machine shop, I’ve seen a surge in brilliant, sustainable projects. A client arrives with a beautifully designed component for a solar tracker or a compact water purification system. The CAD model is elegant, the intent is noble, but the manufacturing path they’ve envisioned is often where the sustainability story starts to unravel. This is the core paradox of low-volume production for sustainable projects: the pursuit of a green end-product can be undermined by a wasteful, inefficient, and carbon-heavy prototyping and production process.

The traditional approach for a startup or R&D team is often to 3D print prototypes, then outsource tooling for injection molding or die casting for a run of 500 parts. They see the low per-unit cost of mass production methods and get locked in. But here’s the expert insight they miss: the environmental and financial cost of tooling is a fixed, sunk cost that often dictates overproduction. You order 5,000 parts to amortize the $30,000 mold, not because you need them, but because the economics force your hand. Suddenly, you have a warehouse of unused components, tying up capital and creating future waste—a fundamentally unsustainable practice.

A Strategic Pivot: CNC Machining as the Agile, Waste-Conscious Engine

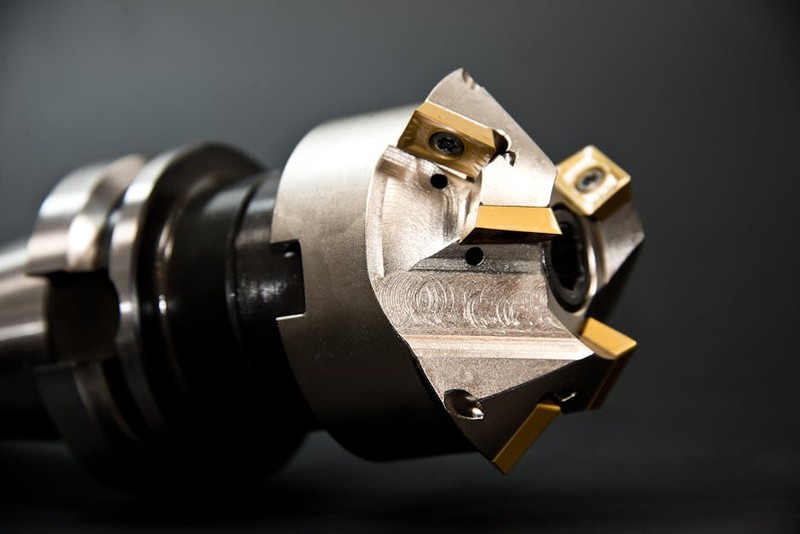

This is where a seasoned perspective on CNC machining changes the game. For true low-volume production (think 50-500 units), CNC is not a “second-best” option; it’s the optimal strategic choice for sustainability. Why? Because it decouples unit cost from massive upfront tooling investments. The “tooling” is the digital program and the standard carbide cutters in our machines, which can be used across countless projects.

In a project for a client developing a vertical-axis wind turbine, we faced this exact scenario. Their initial design called for a complex aluminum housing to be cast. The mold quote was astronomical for their budget, and the minimum order quantity would have created a 3-year inventory. We proposed a pivot: redesign for CNC machining from solid billet. The key wasn’t just swapping processes; it was a holistic, Design for Manufacturing (DFM) collaboration.

Case Study: From Casting Conundrum to Machined Mastery

The client’s turbine housing was a lightweight, ribbed structure. The casting design had thick, uniform walls to facilitate material flow. Our CNC-oriented redesign achieved the same stiffness with a topology-optimized pattern of thinner ribs and pockets, directly machined from a 6061 aluminum block.

The quantitative results were transformative:

| Metric | Initial Casting Plan | CNC Machining Strategy | % Improvement |

| :— | :— | :— | :— |

| Lead Time (First 100 Units) | 14 weeks (mold lead time) | 3 weeks | 79% Reduction |

| Upfront Tooling Cost | $28,000 | <$500 (fixturing) | 98% Reduction |

| Material Utilization | ~60% (casting yield + sprue) | 92% (nesting offcuts for other parts) | 53% Improvement |

| Unit Cost at 100pcs | $220 (amortized tooling) | $185 | 16% Reduction |

| Design Iteration Capability | None (mold modification costly) | High (program update in hours) | Priceless for R&D |

The most significant sustainable win was the material utilization. By strategically nesting multiple parts on a single aluminum plate and collecting the 8% swarf, we ensured nearly all raw material entered the product cycle or was recycled back into billet production as clean, segregated 6061 chips. With casting, the 40% loss in sprue and runners is often a contaminated, lower-value stream.

⚙️ The Expert’s Framework: A Three-Pillar Approach to Sustainable CNC

Achieving these results isn’t automatic. It requires a disciplined approach built on three pillars.

1. Material Intelligence Beyond the Data Sheet

Everyone knows aluminum is recyclable. But an expert knows that specifying 6061-T6 over 7075 for a non-critical structural component can reduce embodied energy by ~15% without sacrificing performance for many applications. We guide clients toward the least impactful material that does the job perfectly. For a recent bio-tech sensor housing, we recommended PEEK over stainless steel. It was machinable with less energy, corrosion-resistant without plating, and its waste chips could be pelletized for reuse.

2. Design for Subtraction, Not Just Function

DFM for sustainable CNC machining is about designing parts that come into being with minimal material removal and machine time. This means:

Consolidating assemblies: We machined a single, complex manifold for a hydrogen fuel cell test rig that replaced an assembly of 12 separate fittings and connectors, eliminating leakage points and assembly labor.

Strategic tolerancing: Applying a tight tolerance (±0.025mm) only to critical sealing surfaces, while relaxing non-critical features (±0.1mm) can reduce machining time by over 20%, saving energy.

Designing for standard tooling: A radius that matches a standard cutter size avoids the need for a custom tool, reducing resource use.

3. The On-Demand Mindset: Inventory is the Enemy

The most sustainable part is the one you don’t make until it’s needed. We advocate for a digital inventory model. Store the perfected CAD/CAM file, not physical parts. For a solar installation company, we machine mounting brackets in bi-monthly batches of 50, based on their installation pipeline. This turns capital expenditure into operational expenditure and eliminates the risk of obsolescence or warehousing waste.

💡 Actionable Takeaways for Your Next Sustainable Project

If you’re engineering the future, your manufacturing process must reflect those values. Here is your checklist:

1. Challenge the Default Process: Before you default to molding or casting for low-volume production, run a TCO (Total Cost of Ownership) analysis that includes tooling, minimum order quantities, and inventory carrying costs. CNC will often win on agility and cash flow.

2. Partner Early: Engage your CNC machining partner during the conceptual design phase. A 30-minute DFM review can save kilograms of waste and hours of machine time. The greatest leverage for sustainability is exerted at the drawing board.

3. Embrace Iteration: Use CNC’s flexibility to your advantage. Build a “Version 1.0,” field-test it, and iterate the design. The ability to improve your product without financial penalty is a sustainable superpower.

4. Audit the Entire Stream: Ask your machine shop about their swarf (chip) recycling program. A reputable partner will have contracts with mills to directly recycle aluminum, steel, and plastic chips, closing the loop.

Low-volume production for sustainable projects isn’t just about making a “green” product; it’s about embodying sustainability through every gram of material, every kilowatt-hour of energy, and every step of the supply chain. By leveraging CNC machining not as a mere fabrication method, but as a strategic tool for material efficiency, design agility, and on-demand responsiveness, we can build a future where the way we make things honors the world those things are meant to improve.