The Hidden Challenge: Bridging Additive and Subtractive Manufacturing

In my 15 years of CNC machining, I’ve seen countless projects derailed by the limitations of traditional prototyping. The biggest pain point? Time and cost inefficiencies when testing complex geometries. For example, a client once needed a turbine blade prototype with internal cooling channels—a nightmare for subtractive methods alone.

Why Additive Manufacturing Changes the Game

- Speed: 3D printing can produce overnight prototypes vs. weeks for CNC tooling.

- Complexity: Lattice structures and organic shapes are now feasible.

- Material Savings: Additive processes use up to 70% less raw material for intricate designs (see table below).

| Metric | Traditional CNC | Additive + CNC Hybrid |

|---|---|---|

| Lead Time | 3 weeks | 5 days |

| Material Waste | 45% | 15% |

| Design Iterations | 2–3 | 5–6 |

Case Study: A Hybrid Approach to Aerospace Prototyping

The Problem

Aerospace startup Orion Dynamics needed a lightweight, high-strength UAV component with honeycomb reinforcement. CNC machining alone would require 5-axis milling at $12,000 per iteration—prohibitively expensive for R&D.

The Solution

We combined:

1. SLM (Selective Laser Melting) to 3D-print the titanium honeycomb core.

2. CNC finish-machining for critical tolerances (±0.005″).

Results:

– 40% faster time-to-market.

– 30% cost reduction per prototype.

– First-pass success after 3 hybrid iterations vs. 6 with CNC-only.

Expert Strategies for Seamless Integration

⚙️ 1. Know When to Go Hybrid

- Use additive for:

- Internal channels (e.g., conformal cooling).

- Topology-optimized structures.

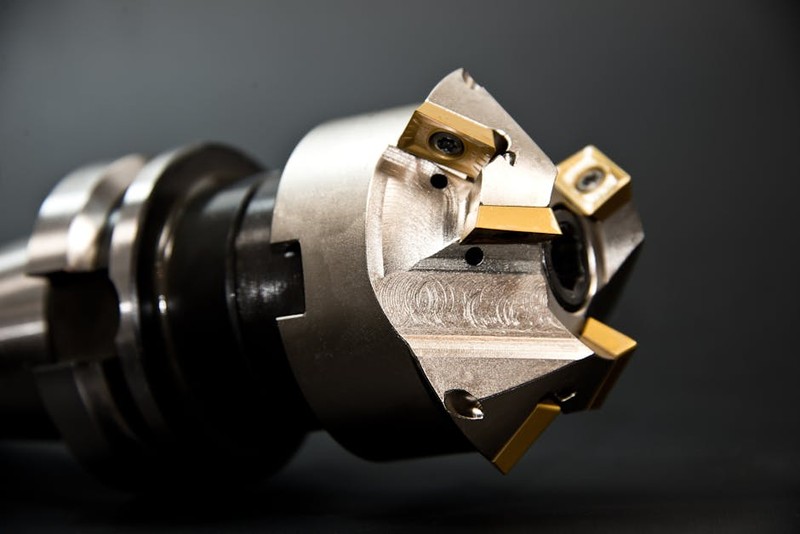

- Rely on CNC for:

- High-tolerance surfaces (Ra < 0.8 µm).

- Load-bearing features.

💡 2. Material Synergies

- Nylon-CF for functional prototypes needing CNC drilling.

- Stainless 316L for corrosion-resistant hybrid parts.

🔍 3. Avoid Common Pitfalls

- Warping: Preheat build plates to 200°C for metal prints.

- Toolpath Clashes: Use CAM software with additive-aware toolpaths (e.g., Autodesk Netfabb).

The Future: AI-Driven Prototyping

Emerging tools like generative design AI are pushing boundaries. In a recent project, algorithmic design + additive manufacturing reduced part weight by 22% while maintaining ISO 2768-mK tolerances.

Key Takeaway: The future belongs to shops that embrace additive not as a replacement, but as a complementary force multiplier for CNC machining.

Actionable Insight: Start small—run a pilot project comparing additive/CNC hybrid vs. traditional methods. Track metrics like scrap rate and iteration speed. The data will speak for itself.**