Why Rapid Prototyping & Local 3D Printing Matter for Manufacturers

In today’s competitive manufacturing landscape, speed and precision are non-negotiable. Rapid prototyping with 3D printing allows businesses to iterate designs quickly, test functionality, and bring products to market faster than traditional methods. But finding reliable rapid prototyping 3D printing near me ensures shorter lead times, lower shipping costs, and better collaboration with local experts.

Let’s explore the key benefits, challenges, and best practices for leveraging local rapid prototyping and 3D printing services effectively.

🔧 Challenges in Rapid Prototyping & 3D Printing

While 3D printing and CNC machining offer immense advantages, manufacturers often face hurdles in execution. Here are the most common challenges:

1. Material Limitations & Selection

Not all materials are suitable for every prototyping need. Factors like strength, flexibility, and heat resistance must align with the final product requirements.

– Plastics (PLA, ABS, Nylon): Great for concept models but may lack durability.

– Metals (Aluminum, Titanium, Stainless Steel): Ideal for functional prototypes but costlier.

– High-Temperature Resins: Necessary for aerospace or automotive applications.

2. Dimensional Accuracy & Surface Finish

3D printing can sometimes produce rough surfaces or slight dimensional deviations, requiring post-processing. CNC machining, however, offers tighter tolerances (±0.005 in) for precision parts.

3. Speed vs. Cost Trade-offs

While 3D printing accelerates prototyping, some methods (like SLS or metal printing) can be expensive for large batches. Hybrid approaches (3D printing + CNC machining) often provide the best balance.

✅ Solutions for Optimizing Rapid Prototyping

1. Partner with Local Experts

Finding rapid prototyping 3D printing near me means:

✔ Faster turnaround times

✔ Easier design revisions with face-to-face collaboration

✔ Reduced logistics costs

2. Choose the Right Technology for the Job

| Method | Best For | Tolerances |

|---|---|---|

| FDM 3D Printing | Low-cost concept models | ±0.2 mm |

| SLA/DLP | High-detail prototypes | ±0.05 mm |

| CNC Machining | Precision metal/plastic parts | ±0.005 in |

| SLS (Nylon) | Durable, functional parts | ±0.1 mm |

| ### 3. Optimize Design for Manufacturability (DFM) | ||

| – Minimize overhangs & supports to reduce post-processing. | ||

| – Use uniform wall thickness to prevent warping. | ||

| – Consider CNC-friendly features if transitioning to mass production. | ||

| — | ||

| ## 📊 Real-World Applications of Rapid Prototyping | ||

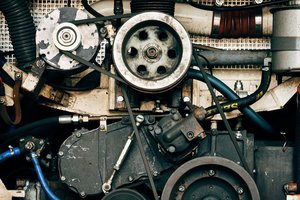

| ### Case Study: Automotive Component Testing | ||

| A local automotive supplier used CNC-machined aluminum prototypes to test a new engine bracket. By working with a nearby rapid prototyping service, they reduced testing time by 40% compared to outsourcing overseas. | ||

| ### Medical Device Development | ||

| A biotech startup leveraged SLA 3D printing for surgical tool prototypes, allowing quick iterations before finalizing FDA-approved production methods. | ||

| — | ||

| ## How to Find the Best Rapid Prototyping 3D Printing Near Me | ||

| 1. Search for Local Specialists – Look for providers with both 3D printing and CNC capabilities for flexibility. | ||

| 2. Check Turnaround Times – Ensure they meet your project deadlines. | ||

| 3. Review Material Options – Confirm they offer the right polymers, metals, or composites. | ||

| 4. Ask About Post-Processing – Smoothing, painting, or machining may be needed. | ||

| — | ||

| ## Final Thoughts: Leveraging Local Rapid Prototyping for Competitive Advantage | ||

| Investing in rapid prototyping 3D printing near me isn’t just about convenience—it’s about speed, cost-efficiency, and collaboration. By selecting the right local partner and optimizing your design process, you can bring high-quality prototypes to market faster and stay ahead of the competition. | ||

| Need a reliable rapid prototyping solution? [Contact us] today to discuss your project requirements with our local experts. |