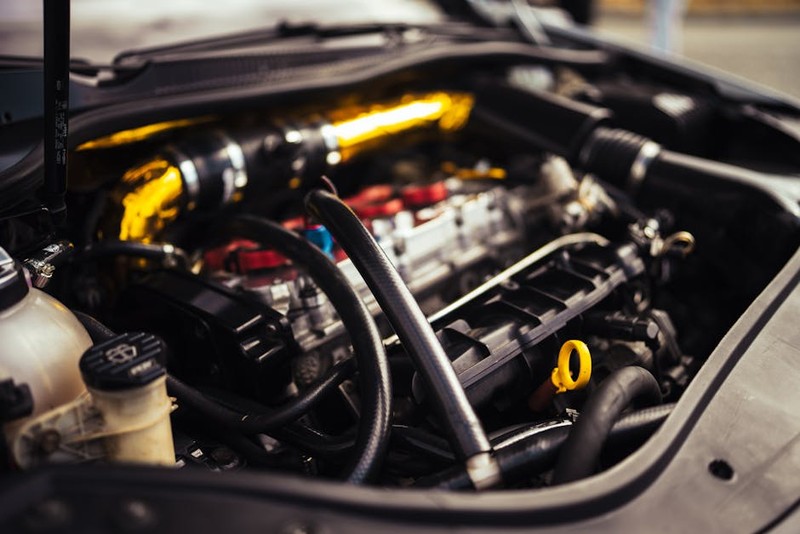

The Hidden Challenge: Machining Hardened Automotive Components

In the automotive industry, components like fuel injectors, transmission gears, and turbocharger blades demand extreme precision and durability. These parts often require machining after heat treatment to avoid distortion, but traditional CNC methods struggle with hardened steels and exotic alloys. This is where Electrical Discharge Machining (EDM) shines—delivering micron-level accuracy without compromising material integrity.

Why EDM Outperforms Conventional CNC for Critical Automotive Parts

- No Contact, No Stress: Unlike milling or turning, EDM uses electrical discharges to erode material, eliminating tool wear and mechanical stress.

- Hardened Material Mastery: Capable of machining materials up to 65 HRC (e.g., D2 tool steel, carbide inserts) with ease.

- Complex Geometries: Achieves sharp corners, deep slots, and fine details impossible with rotary tools.

In one project, a Tier 1 automotive supplier faced a 40% scrap rate when milling heat-treated gear molds. Switching to wire EDM reduced scrap to under 5% while cutting machining time by 30%.

Case Study: Optimizing Fuel Injector Nozzles with Sinker EDM

The Problem

A client needed to produce fuel injector nozzles with 0.1mm diameter orifices in hardened stainless steel. Traditional drilling caused micro-fractures and inconsistent flow rates, leading to failed emissions tests.

The EDM Solution

- Tooling Design: Custom graphite electrodes were machined to mirror the nozzle’s inverse geometry.

- Process Parameters: Fine-tuned pulse duration (2µs) and current (3A) to minimize recast layer formation.

- Post-Processing: Used ultrasonic cleaning to remove debris without damaging the orifice.

Results:

| Metric | Before EDM | After EDM |

|——–|————|———–|

| Scrap Rate | 25% | 3% |

| Flow Rate Consistency | ±8% | ±1.5% |

| Production Time per Unit | 12 min | 7 min |

Key Takeaway: EDM’s non-contact process eliminated tool deflection and micro-cracking, ensuring consistent performance critical for emission compliance.

Expert Strategies for Maximizing EDM Efficiency

1. Electrode Material Selection

- Copper: Best for fine finishes (Ra 0.2µm) but wears faster.

- Graphite: Ideal for high-speed roughing (3x faster than copper) but requires tighter spark gap control.

2. Adaptive Flushing Techniques

- For Deep Cavities: Use dual-flush systems (top + side) to prevent arcing.

- For Thin Features: Reduce dielectric pressure to avoid part deflection.

3. Hybrid Manufacturing

Combine wire EDM with 5-axis milling:

– Example: A turbocharger housing required both intricate internal channels (EDM) and large-scale material removal (CNC). The hybrid approach cut total lead time by 22%.

The Future of EDM in Automotive: Automation and AI

Trend Alert: Automated EDM cells with in-process monitoring are reducing human intervention. One OEM integrated AI-driven spark gap adjustment, boosting throughput by 18% while maintaining ±2µm tolerances.

Pro Tip: Invest in EDM machines with adaptive control systems to dynamically adjust parameters based on real-time feedback—critical for high-volume automotive runs.

Conclusion: EDM as a Competitive Edge

From fuel injectors to EV battery components, EDM machining is unlocking new possibilities for automotive manufacturers. The key to success lies in process optimization, material science, and embracing automation. Whether you’re battling scrap rates or pushing the limits of precision, EDM offers a proven path to reliability and cost savings.

Ready to transform your automotive component production? Share your toughest machining challenge in the comments—let’s solve it together.