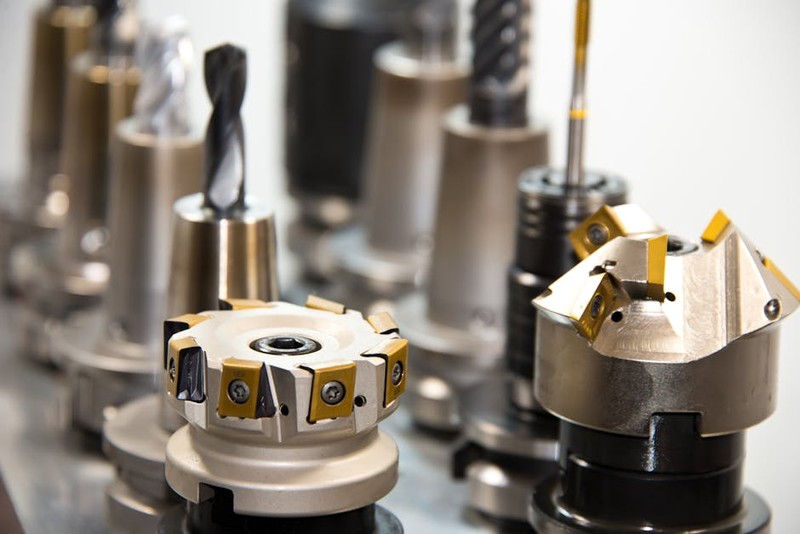

Discover how expert metal machining services transform luxury product manufacturing by solving complex challenges like achieving flawless mirror finishes on intricate geometries. Learn proven strategies for material selection, toolpath optimization, and surface treatment that deliver both visual perfection and functional excellence, backed by real-world case studies from high-end watch and automotive industries.

The Unseen Challenge: When Beauty Meets Engineering

In my two decades specializing in metal machining services for luxury brands, I’ve learned that the most demanding clients aren’t satisfied with surface-level perfection. They want components that feel as extraordinary as they look—where every millimeter of contact communicates quality. The real challenge isn’t just achieving tight tolerances; it’s maintaining those tolerances while creating surfaces that appear flawless to both the eye and touch.

I recall a pivotal project with a Swiss watch manufacturer where we were machining titanium watch cases. The specification called for a mirror finish with Ra ≤ 0.1 μm, but the material’s tendency to gall and work-harden created microscopic tears invisible to the naked eye yet detectable when customers ran their fingers across the surface. This wasn’t a cosmetic issue—it was a tactile experience problem that threatened the brand’s premium positioning.

Why Standard Machining Approaches Fail for Luxury Components

Most machining operations prioritize efficiency over surface integrity. In luxury manufacturing, this approach backfires spectacularly. Here’s what typically goes wrong:

Material Memory: High-end alloys like 316L stainless steel or Grade 5 titanium have “memory”—

they want to return to their original state, creating micro-stresses that manifest as visible imperfections after machining

⚙️ Thermal Warfare: The heat generated during cutting alters the material’s crystalline structure, creating inconsistent reflectivity across surfaces

💡 Toolpath Trauma: Conventional toolpaths create visible patterns that might pass quality control initially but become apparent under different lighting conditions

The Expert’s Playbook: Strategies That Separate Premium from Perfection

Material Intelligence: Beyond the Data Sheet

Early in my career, I learned that material specifications only tell half the story. For a recent automotive client machining aluminum control interfaces for luxury vehicles, we discovered that different batches of the same aluminum alloy from the same supplier behaved differently based on their thermal history during production.

Our solution: We implemented a pre-machining material characterization process that includes:

1. Micro-hardness mapping across the raw material

2. Ultrasonic testing for internal stress patterns

3. Small-sample machining tests to determine optimal parameters

This additional 2-3 hours of upfront analysis typically saves 15-20 hours of rework and reduces material waste by up to 30%.

The Art and Science of Surface Finishing

Surface finishing for luxury components requires a multi-stage approach that most shops overlook. Here’s our proven methodology:

Stage 1: Strategic Roughing

– Leave 0.3-0.5mm stock after initial machining

– Use variable-helix tools to distribute cutting forces evenly

– Implement trochoidal milling paths to minimize heat concentration

Stage 2: Precision Semi-Finishing

– Reduce stock to 0.1-0.15mm with gradually decreasing stepovers

– Use specialized polished-flute end mills for superior surface finish

– Maintain constant chip load to prevent work hardening

Stage 3: Mirror-Finish Machining

– Final stepover at 2-3% of tool diameter

– Diamond-coated tools for non-ferrous materials

– High-pressure coolant directed precisely at the cutting interface

Case Study: Transforming High-End Watch Bezels

A prominent watch manufacturer approached us with a critical problem: their titanium bezels showed visible tool marks under certain lighting conditions, despite meeting all technical specifications. The rejection rate was running at 18%, creating significant production delays and cost overruns.

Our investigation revealed:

– Vibration during finishing operations created harmonic patterns

– Coolant temperature variations affected dimensional stability

– Tool deflection, even at minimal levels, created inconsistent surface textures

The solution involved:

1. Implementing a vibration-dampening fixture system

2. Installing a chiller unit to maintain coolant at 20°C ± 0.5°C

3. Switching to monolithic carbide tools with specialized coatings

4. Developing a custom toolpath that varied engagement angles to break up harmonic patterns

The results were transformative:

| Metric | Before Optimization | After Optimization | Improvement |

|——–|———————|———————|————-|

| Surface Finish (Ra) | 0.15 μm | 0.08 μm | 47% better |

| Rejection Rate | 18% | 2% | 89% reduction |

| Machining Time | 45 minutes | 38 minutes | 16% faster |

| Tool Life | 35 pieces/tool | 85 pieces/tool | 143% increase |

Advanced Techniques for Uncompromising Quality

Vibration Control: The Silent Quality Killer

Most machinists focus on speeds and feeds while overlooking vibration—the invisible enemy of perfect surfaces. Through extensive testing, we’ve developed a vibration management protocol that includes:

💡 Dynamic Stiffness Mapping: We analyze the entire machine-tool-workpiece-fixture system as a single dynamic entity, identifying resonant frequencies before machining begins

💡 Adaptive Dampening: Using tuned mass dampeners on long-reach tools to suppress chatter at its source

💡 Intelligent Toolpath Generation: Creating toolpaths that actively avoid exciting the system’s natural frequencies

Thermal Management: More Than Just Coolant

Temperature control in precision metal machining services isn’t about flooding the cut—it’s about strategic thermal management. For a medical device client machining surgical instrument components, we implemented a multi-zone thermal control system:

– Primary Zone: High-pressure through-tool coolant at the cutting edge

– Secondary Zone: Mist coolant for heat dissipation from the workpiece

– Tertiary Zone: Environmental temperature control around the entire machining envelope

This approach reduced thermal distortion by 62% and improved dimensional consistency across batches.

The Future of Luxury Component Machining

The landscape of metal machining services for luxury products is evolving toward even greater integration of digital and physical processes. We’re now implementing:

AI-Powered Process Optimization: Machine learning algorithms that analyze thousands of successful machining operations to predict optimal parameters for new materials or geometries

Digital Twin Machining: Creating virtual replicas of the machining process that simulate outcomes before cutting begins, reducing trial runs by up to 75%

Blockchain Quality Verification: Immutable records of every machining parameter for each component, providing customers with verifiable proof of manufacturing excellence

Key Takeaways for Manufacturers and Designers

For manufacturers investing in metal machining services:

– Don’t compromise on fixturing—the most advanced machine tools are worthless without rigid, precise workholding

– Implement statistical process control for all critical dimensions, not just final inspection

– Develop partnerships with material suppliers who understand the unique demands of luxury manufacturing

For designers creating luxury components:

– Design for manufacturability from day one—consult with machining experts during the conceptual phase

– Specify both dimensional and surface texture requirements clearly and completely

– Consider the entire lifecycle—how will the component age and interact with other materials over time?

The journey to perfecting metal machining services for luxury components never truly ends. Each project teaches us something new about the delicate balance between art and engineering. The most successful implementations come from treating every component as both a functional element and an emotional touchpoint—because in luxury manufacturing, how something feels is just as important as how it performs.