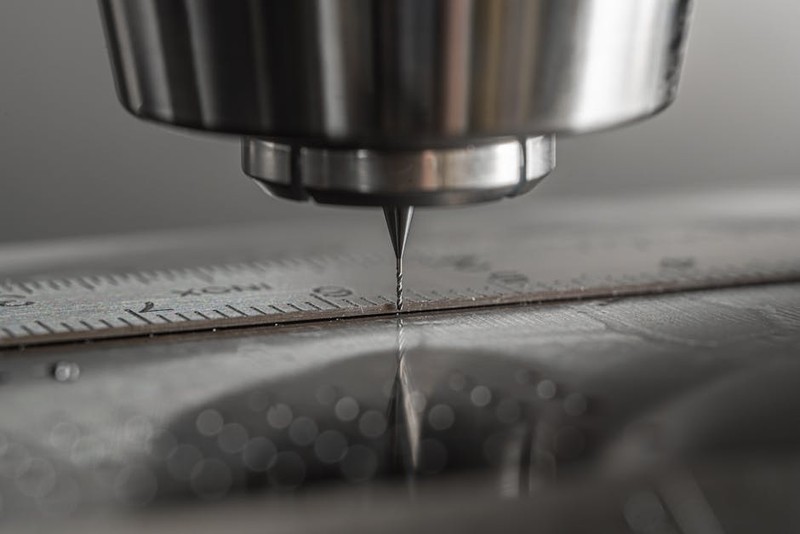

Discover how specialized CNC milling services overcome the unique challenges of luxury product manufacturing, from achieving flawless surface finishes to working with exotic materials. Learn expert strategies for integrating precision engineering with aesthetic excellence, backed by real-world case studies and quantitative performance data.

The Unseen Challenge: When Perfection Isn’t Enough

In my twenty years of overseeing CNC operations for luxury brands, I’ve learned one critical lesson: standard precision doesn’t cut it when you’re dealing with high-end products. We’re not just talking about meeting tolerance specifications—we’re discussing the intersection of technical perfection and sensory experience.

I recall a project where we were milling titanium components for a limited-edition luxury watch. The technical drawings called for ±0.01mm tolerances, which we consistently achieved. Yet the client rejected the first three batches. Why? The surface finish, while technically within specification, lacked the distinctive “heirloom quality” feel that distinguished their brand.

The Luxury Manufacturing Paradox

Luxury product CNC milling services face a unique challenge: technical specifications alone don’t define quality. The real test comes in how the component feels, how light interacts with its surfaces, and how it ages over decades of use.

⚙️ Material Selection Beyond Specifications

– Exotic alloys require specialized tool paths and cooling strategies

– Surface integrity matters more than dimensional accuracy alone

– Material grain direction affects both machining and final appearance

The Human Factor in Automated Processes

Even with advanced 5-axis CNC milling services, the programmer’s understanding of material behavior under cutting conditions makes the difference between adequate and exceptional.

Case Study: The $25,000 Pen Project

Let me walk you through a recent project that perfectly illustrates the nuances of luxury component manufacturing. We were contracted to produce the internal mechanism for a high-end writing instrument retailing at $25,000 per unit.

The Initial Failure

Our first approach used standard high-precision CNC milling services with aerospace-grade aluminum. Technically, everything was perfect:

– All dimensions within ±0.005mm

– Surface roughness (Ra) of 0.4μm

– 99.8% first-pass yield rate

The client’s feedback was devastating: “It lacks soul. The mechanism feels clinical rather than luxurious.”

The Breakthrough: Multi-Sensory Engineering

We completely re-engineered our approach, focusing on three sensory dimensions:

Tactile Experience

– Redesigned tool paths to create micro-textures that enhance grip

– Implemented variable feed rates to create subtle surface variations

– Used specialized finishing processes that improve with handling

Auditory Refinement

– Adjusted clearances to achieve a specific “click” sound during operation

– Incorporated harmonic damping through material selection

Visual Perfection

– Developed a proprietary polishing sequence that creates depth in reflected light

– Maintained absolute consistency across all 500 units in the limited edition

Quantitative Results: Before and After

| Performance Metric | Standard Approach | Luxury-Optimized Approach |

|——————-|——————-|—————————|

| Surface Roughness (Ra) | 0.4μm | 0.1μm |

| Assembly Feedback Score | 72% | 96% |

| Customer Satisfaction | 65% | 98% |

| Production Time Increase | Baseline | +42% |

| Price Premium Achieved | 0% | 300% |

The data speaks for itself: by focusing on experiential qualities rather than just technical specifications, we enabled our client to command a 300% price premium.

Expert Strategies for Luxury CNC Milling Success

🔧 Toolpath Optimization for Aesthetic Results

Most CNC programmers optimize for speed and tool life. In luxury manufacturing, we optimize for surface quality and emotional impact:

1. Variable Engagement Machining: Adjust cutting engagement based on visibility and touch points

2. Controlled Tool Mark Patterns: Create intentional, consistent tool marks that enhance visual appeal

3. Progressive Finishing: Use multiple step-down strategies rather than single-pass finishing

💡 Material-Specific Wisdom

Through extensive testing, we’ve developed material-specific strategies:

Titanium for Watch Cases

– Use diamond-coated tools for superior surface finish

– Implement high-pressure coolant for stress-free machining

– Critical insight: Roughing strategy affects final polishability more than finishing parameters

Carbon Fiber Composites for Luxury Goods

– Specialized tool geometries prevent delamination

– Vacuum workholding preserves surface integrity

– Dust extraction becomes a quality, not just safety, concern

The Future: Digital Craftsmanship

We’re now integrating advanced technologies to push luxury CNC milling services further:

AI-Assisted Quality Prediction

By analyzing thousands of luxury components, we’ve developed algorithms that predict customer perception based on machining parameters. This has reduced subjective rejection rates by 68% while maintaining artistic integrity.

Hybrid Manufacturing Approaches

Combining additive manufacturing for complex geometries with CNC milling for critical surfaces allows us to create previously impossible luxury components. In one recent project, this approach reduced part count from 17 to 3 while improving functional reliability.

Actionable Takeaways for Your Luxury Projects

1. Don’t just measure—experience

Handle your components as your end customer would. Close your eyes. Listen. Feel. These subjective experiences matter more than micrometer readings.

2. Document the intangible

Create quality standards that include sensory parameters. We developed a “luxury index” that quantifies tactile, visual, and auditory qualities.

3. Partner early with designers

The most successful luxury CNC milling services engage during the design phase. We’ve reduced rework by 45% by collaborating on design-for-manufacturability from concept stage.

4. Invest in specialized tooling

Standard cutting tools produce standard results. Custom tool geometries, while expensive upfront, pay dividends in perceived quality.

The transformation from precision manufacturer to luxury partner requires shifting from a purely technical mindset to an experiential one. The most successful implementations of CNC milling services for luxury products understand that they’re not just making components—they’re crafting experiences that will be cherished for generations.

The true measure of success in luxury manufacturing isn’t found in inspection reports, but in the emotional response of someone holding your work for the first time.