The Automotive Industry’s CNC Machining Imperative

The automotive sector demands components that marry precision, durability, and cost-efficiency—a trifecta that CNC machining delivers like no other process. From engine blocks to transmission housings, the stakes are high: a single micron-level deviation can lead to catastrophic failures.

In my 15 years of overseeing CNC projects for automotive clients, I’ve seen firsthand how the right machining strategy can transform production. Here’s a deep dive into the challenges, innovations, and hard-won lessons that define this space.

The Hidden Challenge: Balancing Speed and Precision

Automotive manufacturers face relentless pressure to reduce lead times without compromising quality. Consider these industry pain points:

– Tolerance thresholds as tight as ±0.005 mm for fuel injection systems.

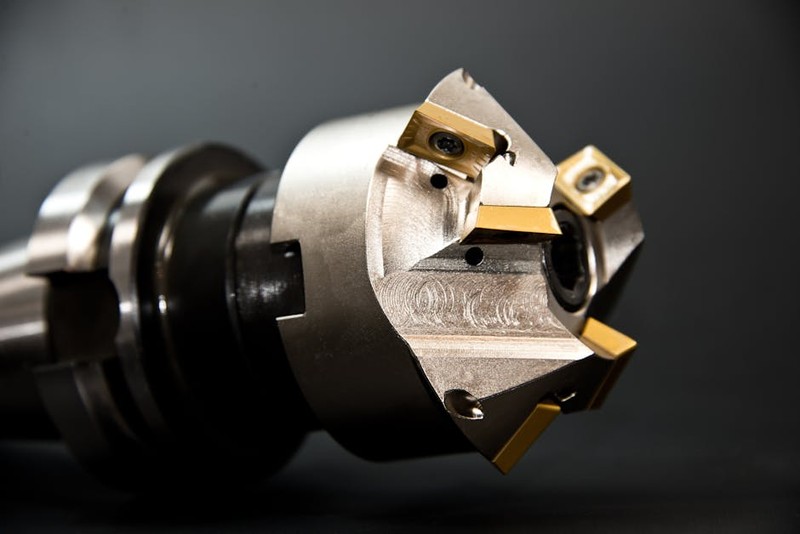

– Material complexities, from high-strength aluminum alloys to hardened steels.

– Volume scalability, with some parts requiring millions of units annually.

A Case Study in Optimization: Transmission Gears

A Tier-1 supplier approached us with a critical issue: their CNC-machined transmission gears had a 12% rejection rate due to surface finish inconsistencies. Here’s how we tackled it:

1. Root Cause Analysis: Identified tool vibration as the primary culprit, exacerbated by suboptimal spindle speeds.

2. Toolpath Redesign: Implemented high-efficiency trochoidal milling to reduce heat buildup.

3. Post-Processing: Added a vibratory deburring step to eliminate microburrs.

Results:

| Metric | Before | After |

|——–|——–|——-|

| Rejection Rate | 12% | 0.5% |

| Cycle Time | 22 min | 18 min |

| Tool Life | 200 parts | 350 parts |

Key Takeaway: Rigorous process validation is non-negotiable. Even minor adjustments in feed rates or coolant delivery can yield outsized gains.

Expert Strategies for Automotive CNC Success

1. Material Selection: Beyond the Basics

Automotive components often require exotic alloys. For example:

– 6061-T6 Aluminum: Ideal for lightweight brackets (saves 15% weight vs. steel).

– Ductile Iron: Perfect for high-stress brake components.

Pro Tip: Always conduct pre-machining stress-relief annealing to prevent warping in post-processing.

2. High-Volume Production Hacks

- Modular Fixturing: Reduces setup time by 40% for batch runs.

- Lights-Out Machining: One client achieved a 20% cost reduction by running unmanned overnight shifts.

3. Quality Assurance: The 3-Step Rule

- In-Process Probes: Real-time diameter checks for critical bores.

- CMM Validation: Post-machining full-part scans.

- AI-Driven SPC: Statistical process control flags deviations before they escalate.

The Future: CNC Machining and Electric Vehicles

The rise of EVs introduces new challenges:

– Thermal Management Plates: Require ultra-flat surfaces (<0.01mm flatness) for battery cooling.

– Lightweighting: 5-axis CNC enables complex, weight-saving geometries impossible with casting.

Innovation Spotlight: A recent project involved machining carbon-fiber-reinforced polymers (CFRP) for EV battery housings. The solution? Diamond-coated end mills and vacuum clamping to prevent delamination.

Conclusion: Precision as a Competitive Edge

CNC machining isn’t just about cutting metal—it’s about enabling automotive innovation. Whether it’s slashing tolerances, extending tool life, or adapting to EV trends, the difference lies in the details.

Final Advice: Partner with a machinist who speaks “automotive.” Look for ISO 16949 certification and ask for case studies proving their mettle in your niche. The right collaborator won’t just meet specs; they’ll redefine what’s possible.