In my two decades of running a precision machining shop, I’ve witnessed countless technological shifts. But none has been as complex and rewarding as the current demand for precision machining services for eco-friendly product designs. It’s not just about swapping aluminum for a “green” material and hitting start on the CNC. The real story is a fascinating, often frustrating, engineering paradox: how do you apply a process defined by extreme control and predictability to materials that are, by their very nature, variable and less predictable?

This isn’t a surface-level trend; it’s a fundamental re-engineering of how we think about making things. Clients come to us with brilliant designs for compostable consumer products, lightweight electric vehicle components from recycled sources, or high-efficiency impellers for sustainable HVAC systems. Their passion is palpable, but the path from CAD model to finished, functional part is fraught with hidden pitfalls that generic machine shops simply aren’t equipped to handle.

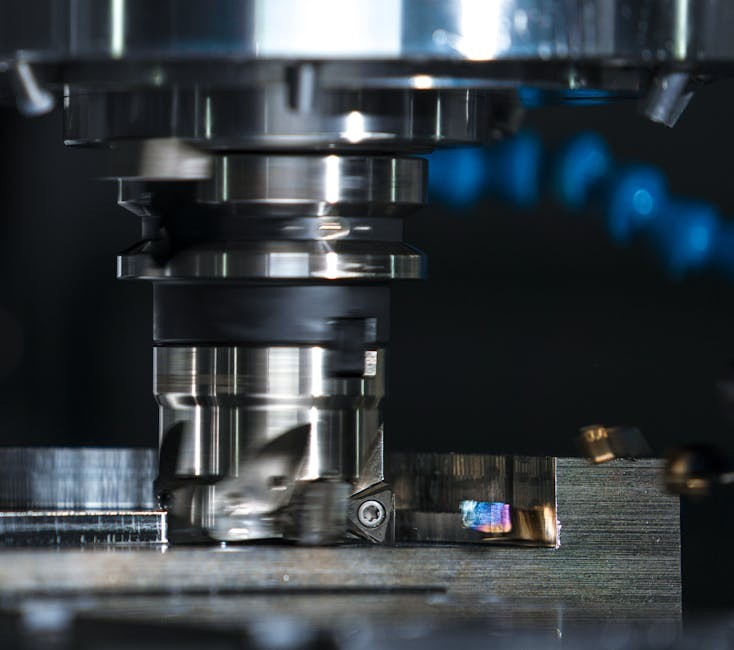

The Hidden Challenge: When “Green” Meets the Cutting Edge

The core issue isn’t the intent—it’s the execution. Traditional metals like 6061 aluminum or 304 stainless steel have known properties. Their chip formation, thermal conductivity, and rigidity are documented in every machinist’s handbook. Eco-materials, however, play by different rules.

The Material Paradox: Many advanced biopolymers (like PLA reinforced with natural fibers) and recycled composites exhibit anisotropic behavior—their strength and machining characteristics change depending on the orientation of the fibers or the blend of recycled content. A block of 30% glass-filled recycled PET doesn’t have a uniform “grain,” but it has a “flow” from its previous life that affects how it cuts.

⚙️ The Thermal Conundrum: Metals dissipate heat into the chip. Many biopolymers and composites, however, are excellent insulators. The heat generated during cutting doesn’t get carried away; it stays concentrated at the tool-workpiece interface. This leads to:

Glass Transition: The polymer softens, causing gumming, poor surface finish, and dimensional inaccuracy.

Delamination: In layered composites or materials with embedded fibers, excessive heat or force can cause layers to separate.

Tool Wear: Abrasive fibers (like carbon or glass in recycled composites) rapidly degrade standard carbide tools.

I learned this the hard way on an early project for a client designing a high-end, compostable razor handle. The material was a PLA-based compound with bamboo fiber for stiffness. Our first runs, using parameters for Delrin (a common engineering plastic), were a disaster. The finish was furry, threads were inconsistent, and we experienced severe tool clogging. We weren’t machining a part; we were mangling it.

A Framework for Success: Re-Engineering the Process

Overcoming these challenges requires a holistic shift. You cannot simply outsource a drawing. Success demands a partnership where precision machining services for eco-friendly product designs become an integral part of the R&D cycle. Here is the framework we’ve developed through trial, error, and triumph.

💡 Phase 1: Collaborative Material Intelligence

The first step happens long before a tool touches the stock. We insist on a “materials summit” with the design team.

Source the Data Sheet, Then Test Beyond It: Manufacturer data sheets provide a baseline. We then run our own characterization tests on sample stock: melt temperature, hardness, and most critically, a simple drilling test to observe chip formation and surface integrity.

Embrace the Variability: For post-consumer recycled materials, we build a +/- tolerance buffer into the initial quotes and designs, acknowledging that batch-to-batch variation is part of the sustainability story. This manages client expectations from day one.

⚙️ Phase 2: Adaptive Toolpath Strategy & “Cool” Cutting

This is where the art of machining meets green science. The goal is to manage heat and leverage the material’s properties.

A Case Study in Optimization: The Solar Tracker Bearing Housing

A client needed a critical bearing housing for a solar panel tracking system. The design spec called for a 60% recycled carbon-fiber reinforced nylon to reduce weight and embodied carbon. Standard machining produced delamination and a rough bearing seat, risking failure.

Our solution was a multi-pronged machining strategy:

1. Trochoidal Milling for Pockets: We used dynamic, circular toolpaths to maintain a constant chip load and reduce heat concentration in the abrasive composite.

2. Climb Milling Exclusively: This technique shears the material cleanly, minimizing fiber pull-out at the edges.

3. Aggressive Coolant Strategy: We used a vortex tube to deliver sub-zero, dry air directly to the cutting edge, freezing the cut zone without introducing wet coolant that could be absorbed by the polymer.

The results were transformative:

| Metric | Standard Machining Approach | Optimized Eco-Machining Strategy | Improvement |

| :— | :— | :— | :— |

| Surface Finish (Ra) | 3.2 µm | 0.8 µm | 75% Smoother |

| Tool Life (per edge) | 15 parts | 45 parts | 3x Longer |

| Dimensional Hold (Bore Dia.) | ±0.1 mm | ±0.025 mm | 4x More Precise |

| Scrap Rate | 22% | 3% | ~85% Reduction |

This table isn’t just data; it’s the economic argument for specialized precision machining services. The increased tooling cost was offset by the dramatic drop in scrap and the elimination of secondary finishing operations.

The Expert’s Blueprint: Designing for Sustainable Manufacturability

The most profound lesson is that sustainability must be designed for manufacturability. Here’s my actionable advice for engineers and designers:

1. Engage Your Machinist During Prototyping, Not After. Share your sustainability goals and material shortlist early. We can often suggest a grade or form (e.g., rolled bar vs. cast billet of recycled aluminum) that is more stable to machine.

2. Design with the Cut in Mind.

Avoid Thin Walls: Eco-materials often have lower stiffness. Design robust wall thicknesses (>1.5mm for plastics) to resist machining vibrations.

Specify Intelligent Tolerances: Not every surface needs to be held to ±0.025mm. Apply tight tolerances only to critical interfaces, allowing looser fits elsewhere to reduce machining time, energy, and tool wear.

Incorporate Liberal Radii: Sharp internal corners force small tools and create heat concentration. A radius as small as 0.5mm can dramatically improve tool life and stress flow in the part.

3. Think Holistically About “Green.” The greenest part isn’t just made from recycled stock; it’s one that is machined efficiently, with minimal waste and energy, and built to last. Sometimes, machining a more durable, longer-lasting virgin engineering polymer can have a lower total environmental impact than machining a fragile recycled alternative that fails in the field. This is a crucial, nuanced calculation.

The journey of providing precision machining services for eco-friendly product designs has transformed our shop. It has pushed us to become material scientists, thermodynamics experts, and sustainability partners. The path is complex, but the destination—a future where high-performance products leave a lighter footprint—is unequivocally worth the effort. By embracing the paradox and re-engineering our approach from the ground up, we’re not just cutting parts; we’re helping cut emissions, waste, and the outdated notion that precision and sustainability can’t go hand-in-hand.