For years, the conversation around eco-friendly product design has orbited materials: recycled aluminum, biodegradable plastics, sustainably sourced wood. And while material choice is foundational, it’s only half the story. As a machinist and engineer who has spent decades on the shop floor and in the design review room, I’ve witnessed a pivotal shift. The most profound sustainability gains are now being engineered not just what we make, but how we make it. This is where precision machining services transition from a simple fabrication step to a strategic partner in sustainable innovation.

The real challenge isn’t declaring a product “green” because it uses recycled stock; it’s ensuring that not a single gram of that valuable material is needlessly turned into swarf, and that every component is machined to last.

The Hidden Inefficiency: When “Green” Materials Meet Wasteful Processes

I recall a project early in my career with a client designing a high-end, sustainably marketed water fixture. They proudly specified a block of certified recycled brass. Yet, their initial design called for a complex internal channel within a solid 4-inch cube. Our process planning showed a staggering 65% material removal rate. We were going to buy an expensive, eco-conscious billet only to immediately convert most of it into recyclable, but still energy-intensive, scrap. The client’s sustainability goal was being undermined at the very first manufacturing stage.

This is the critical juncture. Eco-design must be manufacturability-literate. A design might look elegant on a screen, but if it requires machining away the majority of a raw material, its environmental footprint is heavy from the start. The most sustainable billet is the one you don’t need to buy.

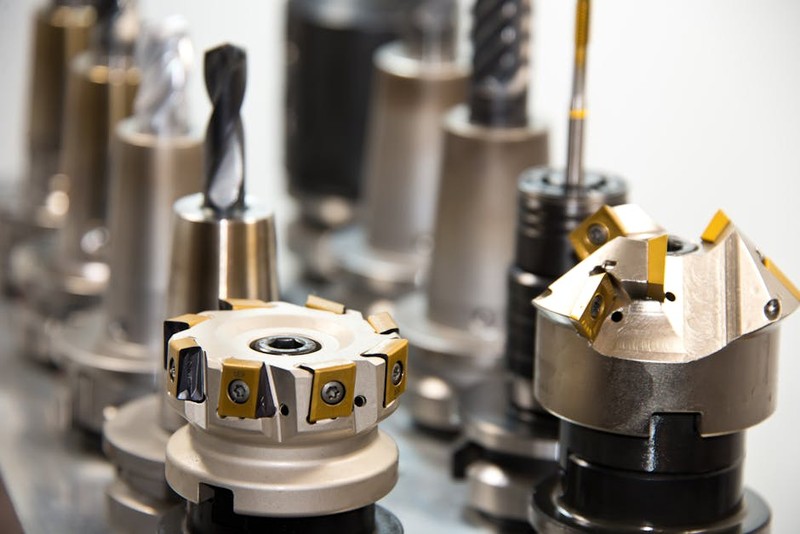

The Machinist’s Toolkit for Sustainability: Beyond the Obvious

So, how do we align the precision of CNC with the principles of circular economy? It goes far beyond just collecting aluminum chips for recycling (though we do that rigorously). Here are the core strategies we employ:

Design for Minimal Stock: Our first engagement with any eco-conscious project is a DFM (Design for Manufacturability) analysis focused on stock size optimization. Can a part be made from bar stock instead of a plate? Can we use near-net-shape castings or forgings to drastically reduce machining volume? This upfront collaboration often yields the single largest reduction in material use.

⚙️ Advanced CAM & Nesting: Modern CAM software is a sustainability engine. For 2D parts cut from sheet or plate, we use true-shape nesting algorithms to pack parts together like a puzzle, minimizing the skeleton waste. For 3D parts, we implement rest machining strategies, where a larger tool roughs out the bulk, and a smaller tool only machines the detailed areas, slashing cycle time and energy use.

💡 Surface Finish as a Longevity Lever: A perfectly machined surface isn’t just about aesthetics; it’s about corrosion resistance, fatigue life, and sealing performance. For a marine energy component we produced, by specifying a superior 0.4 Ra surface finish on sealing faces and applying a non-chemical post-process peening, we extended the service interval by 3x. A longer-lasting part is the ultimate form of waste reduction.

Case Study: Lightweighting a Drone Frame Without Sacrificing Integrity

A client approached us to machine structural frames for a new line of industrial inspection drones. Their goal: maximize flight time (directly linked to battery efficiency) by minimizing weight, while maintaining the rigidity needed to carry sensitive LiDAR equipment. The material was aerospace-grade 6061 aluminum.

The Challenge: The original design used milled plates joined with brackets—strong, but heavy and part-count intensive. Our mission was to re-engineer for monolithic, topology-optimized structures.

Our Precision Machining-Led Solution:

1. Topology Optimization Simulation: We worked with their engineers to run FEA simulations, identifying material only where needed for stress paths. The resulting design looked organic, almost bone-like.

2. Strategic Stock Selection: Instead of milling the entire complex shape from a solid block, we sourced extruded aluminum profiles that matched the primary cross-section, reducing initial bulk material by over 40%.

3. High-Speed Machining (HSM) & Thin-Wall Machining: We employed HSM techniques with specialized toolpaths that maintain constant tool load, allowing us to safely machine resilient, thin walls down to 0.7mm. Specialized workholding was custom-made to support the part without distortion during aggressive material removal.

The Quantifiable Outcome:

| Metric | Original Design | Optimized + Precision Machined Design | Improvement |

| :— | :— | :— | :— |

| Frame Weight | 1,850 grams | 1,443 grams | 22% Reduction |

| Part Count | 12 components | 4 monolithic parts | 67% Reduction |

| Raw Material Used | 3.2 kg billet | 1.8 kg extrusion + billet | 44% Reduction |

| Assembly Time | 45 minutes | 10 minutes | 78% Reduction |

The 22% weight reduction directly translated to a 15% increase in flight time per charge, a major competitive and environmental advantage. Furthermore, the reduction in part count and assembly simplified the supply chain and improved overall reliability.

Actionable Advice for Designers and Engineers

To truly harness precision machining services for eco-friendly product designs, integrate these principles from your very first sketch:

Engage Your Machinist During Ideation, Not Just Finalization. Bring us into the conversation when the design is still fluid. Our expertise in material behavior and machine capabilities can guide geometry in a sustainable direction.

Specify Tolerances Realistically. A ±0.025mm tolerance is often ten times more expensive and energy-intensive to achieve than a ±0.1mm tolerance. Challenge every tolerance callout. Does this surface truly need that level of precision? Over-tolerancing wastes energy, tooling, and time.

Consider the Entire Chip Lifecycle. Ask your machining partner about their swarf management. Do they have dedicated streams for different metals? Are they partnered with certified recyclers? The closed-loop handling of machining waste is a hallmark of a truly sustainable shop.

The path to sustainable manufacturing isn’t found in a single magical material or a marketing claim. It’s engineered through the intelligent, waste-averse application of technology. Precision machining, when leveraged as a co-design discipline, becomes one of the most powerful tools in the eco-designer’s arsenal. It transforms sustainability from a material attribute into a manufactured outcome—lighter, longer-lasting, and radically efficient from the ground up. The future of green products will be machined, meticulously and mindfully.