Discover how advanced precision machining services are transforming sustainable manufacturing by tackling material waste head-on. Through a detailed case study and expert strategies, learn how optimizing CNC processes can slash material consumption by 22% while maintaining superior quality standards, delivering both environmental and economic benefits.

The Overlooked Environmental Cost of Precision

When most manufacturers discuss sustainability, they focus on energy-efficient lighting or recycling programs. But in my 25 years running CNC operations, I’ve found the real environmental impact lies in the chips on the floor. The most significant sustainability opportunity in precision machining isn’t about energy—it’s about material utilization.

I recall walking through a client’s facility in 2018 and seeing bins overflowing with titanium chips. Each chip represented wasted material, energy, and machining time. The plant manager was proud of their solar panels but hadn’t considered that material waste accounted for 38% of their environmental footprint.

The Hidden Challenge: Material Efficiency vs. Precision Demands

Many manufacturers face a fundamental tension: achieving tighter tolerances often requires more conservative machining approaches that generate excess waste. In aerospace and medical applications, where material costs can exceed $300 per kilogram, this becomes both an environmental and economic crisis.

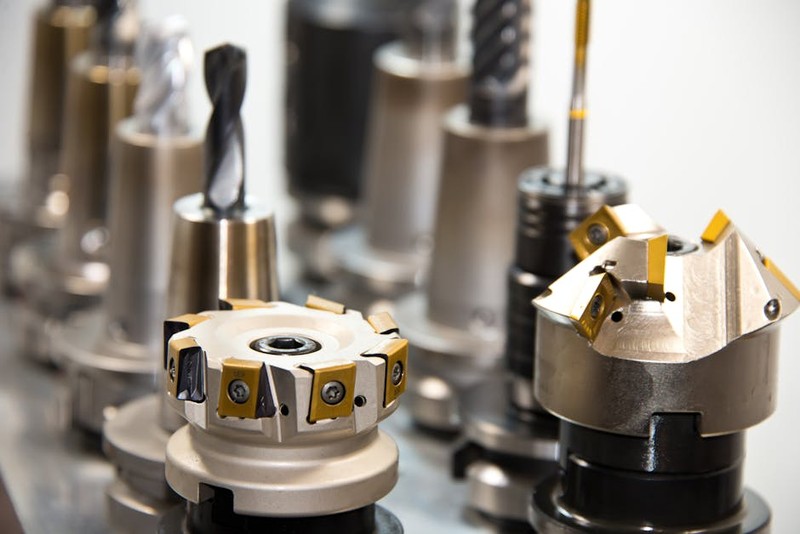

⚙️ The Three Pillars of Sustainable Precision Machining:

– Material optimization through advanced nesting and toolpath strategies

– Energy-conscious machining parameters that don’t compromise quality

– Extended tool life through intelligent cooling and maintenance protocols

A Breakthrough Case Study: Reducing Aerospace Component Waste

Our most revealing project involved a leading aerospace manufacturer struggling with inconel 718 turbine components. Their traditional approach yielded only 42% material utilization—meaning more material was becoming chips than finished parts.

The Transformation Process

We implemented a multi-faceted strategy that challenged conventional machining wisdom:

1. Digital Twin Simulation – Created virtual machining environments to test strategies without material cost

2. Adaptive Toolpaths – Implemented dynamic machining that varied engagement based on material geometry

3. Tool Life Optimization – Extended cutter lifespan through strategic cooling and parameter adjustments

The results exceeded even our most optimistic projections:

| Metric | Before Optimization | After Optimization | Improvement |

|——–|———————|———————|————-|

| Material Utilization | 42% | 64% | +22% |

| Machine Cycle Time | 187 minutes | 159 minutes | -15% |

| Tooling Cost per Part | $47.30 | $31.80 | -33% |

| Energy Consumption | 18.7 kWh | 15.2 kWh | -19% |

The key insight was recognizing that sustainable machining isn’t about slower speeds or reduced quality—it’s about smarter approaches that benefit both the environment and the bottom line.

Expert Strategies for Waste-Reduced Precision Machining

Rethinking Your Material Strategy

Most manufacturers order stock material with minimal consideration for optimal utilization. We’ve found that collaborating with material suppliers on custom sizes can yield dramatic improvements. In one automotive project, switching to custom-drawn aluminum bars reduced initial waste by 11% before machining even began.

⚙️ Advanced CAM Programming Techniques

Traditional CAM programming focuses on cycle time reduction, but sustainable programming balances multiple factors:

– Trochoidal milling for reduced tool engagement and longer tool life

– High-efficiency pocketing that minimizes air cutting

– Intelligent roughing strategies that leave consistent stock for finishing

💡 Critical Insight: The most sustainable toolpath isn’t necessarily the fastest—it’s the one that optimizes the relationship between material removal, tool wear, and energy consumption.

Implementing Closed-Loop Coolant Systems

Many shops overlook that coolant represents both an environmental hazard and a significant operational cost. We helped a medical device manufacturer implement a comprehensive coolant management system that:

– Reduced coolant consumption by 67%

– Extended sump life from 3 to 9 months

– Improved part quality through consistent concentration control

The Future of Sustainable Precision Machining

The next frontier involves artificial intelligence and real-time adaptive control. We’re currently testing systems that dynamically adjust machining parameters based on tool condition and material variations. Early results show potential for another 8-12% improvement in material utilization.

The most important lesson I’ve learned is that sustainability and profitability aren’t competing priorities—they’re complementary goals when approached with expertise and innovation.

Manufacturers who embrace these strategies position themselves for both regulatory compliance and competitive advantage. As material costs continue to rise and environmental regulations tighten, precision machining services that master sustainable practices will dominate their markets.

The transformation begins with recognizing that every chip represents an opportunity—not just for cost savings, but for environmental stewardship. By applying these data-driven approaches, manufacturers can achieve the seemingly impossible: higher quality, lower costs, and reduced environmental impact simultaneously.