🔧 Challenges in Precision Grinding and CNC Machining

Precision grinding is a critical process in manufacturing, ensuring components meet exact specifications for industries like aerospace, automotive, and medical devices. However, achieving flawless results isn’t without hurdles. Let’s explore common challenges and how Badger’s Grinding Services Coventry tackles them.

1. Addressing Material Variability

Different metals and alloys behave unpredictably during grinding, leading to:

– Warping or distortion from excessive heat.

– Tool wear due to hardened materials like titanium or Inconel.

– Surface finish inconsistencies affecting part performance.

Solution: Badger’s employs advanced CNC grinding machines with real-time monitoring to adjust parameters dynamically, minimizing thermal stress and ensuring uniform material removal.

2. Maintaining Tight Tolerances

Many industries demand micron-level precision. For example:

| Industry | Typical Tolerance (mm) |

|---|---|

| Aerospace | ±0.005 |

| Medical Devices | ±0.002 |

| Automotive | ±0.010 |

Solution: Through high-precision CNC grinding and rigorous QA checks, Badger’s guarantees adherence to even the strictest tolerances.

3. Overcoming Surface Finish Imperfections

Poor finishes can lead to part failure. Common issues include:

– Burn marks from excessive friction.

– Micro-cracks due to improper wheel selection.

✅ Best Practice: Using diamond or CBN grinding wheels tailored to material hardness ensures a flawless finish.

✅ Innovative Solutions at Badger’s Grinding Services Coventry

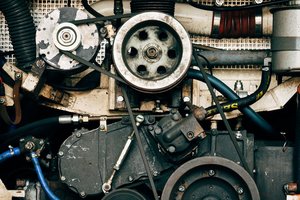

1. State-of-the-Art CNC Grinding Technology

Badger’s invests in the latest CNC grinders, featuring:

– Automated wheel dressing for consistent performance.

– Coolant filtration systems to reduce thermal distortion.

– Multi-axis capabilities for complex geometries.

2. Skilled Workforce and Process Optimization

Even the best machines need expert operators. Badger’s team combines:

– Decades of grinding experience.

– Continuous training on emerging techniques.

– Lean manufacturing principles to reduce waste and boost efficiency.

3. Custom Grinding Solutions

Every project is unique. Whether it’s:

– Large-batch production or prototype development,

– Specialty materials or unconventional shapes,

Badger’s collaborates closely with clients to deliver tailored solutions.

📊 Real-World Applications: Case Studies

Case 1: Aerospace Component Grinding

Challenge: A client needed turbine blades ground to ±0.003mm with no surface defects.

Solution: Badger’s used CNC creep-feed grinding with optimized coolant delivery, achieving a mirror-like finish and perfect dimensional accuracy.

Case 2: Medical Implant Precision

Challenge: Surgical tools required burr-free edges to prevent tissue damage.

Solution: Electrolytic in-process dressing (ELID) grinding ensured ultra-smooth edges, meeting medical-grade standards.

🔧 Key Takeaways for Manufacturers

To replicate Badger’s success in your operations:

1. Invest in advanced CNC grinding technology for consistency.

2. Prioritize operator training to maximize machine potential.

3. Optimize grinding parameters for each material and application.

4. Partner with experts like Badger’s for complex projects.

Final Thoughts

Precision grinding is both an art and a science. By leveraging cutting-edge technology, skilled craftsmanship, and a problem-solving mindset, Badger’s Grinding Services Coventry sets the benchmark for quality. Whether you’re tackling material challenges or chasing micron-level accuracy, their proven methods offer a roadmap to manufacturing excellence.

Need precision grinding solutions? Explore Badger’s capabilities today and elevate your production standards.