The Unique Challenges of Precision Drilling in Williamsport

Williamsport, PA, is a hub for aerospace, medical, and energy industries—all sectors where precision drilling isn’t just a requirement but a make-or-break factor. From my 15 years in CNC machining, I’ve found that local shops face three recurring hurdles:

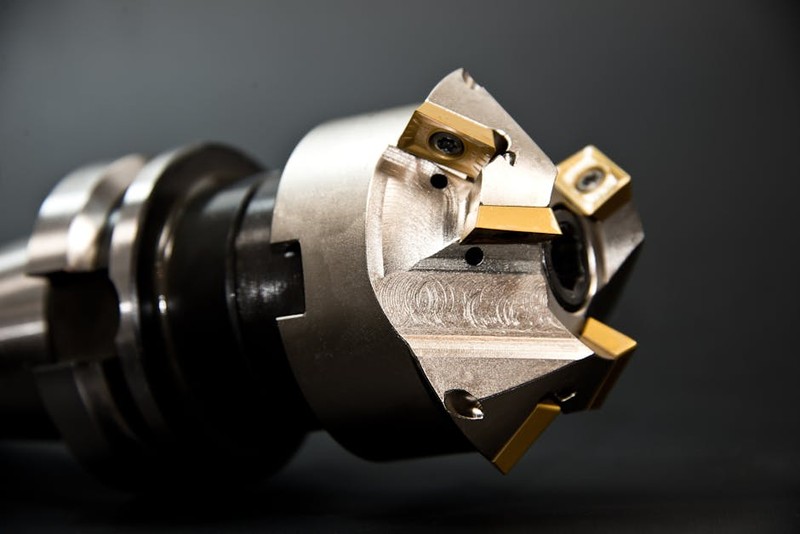

1. Material Variability: The region’s demand for drilling high-strength alloys (e.g., Inconel, titanium) leads to rapid tool wear.

2. Tight Tolerances: Aerospace clients often demand holes with ±0.0005″ tolerances—near-impossible without thermal compensation.

3. Legacy Equipment Limitations: Many shops still use older CNC mills, lacking real-time monitoring for vibration control.

A Case Study: Drilling 500 Holes in a Turbine Component

In 2022, a Williamsport-based manufacturer struggled with a 30% scrap rate on turbine housings due to drill wander in Hastelloy. Here’s how we solved it:

– Tool Selection: Switched from carbide to diamond-coated drills (reducing heat buildup by 40%).

– Peck Drilling Optimization: Adjusted feed rates to 0.001″/rev and peck depth to 1.5x drill diameter.

– Coolant Strategy: Used high-pressure through-tool coolant (1,000 psi) to clear chips.

Results: Scrap rates dropped to 8%, and cycle times improved by 18%.

Expert Strategies for Precision Drilling Success

1. Toolpath Optimization: Beyond G-Code Basics

Most CAM software defaults to linear drilling paths, but helical interpolation can reduce deflection. In a recent project:

| Approach | Hole Straightness Error | Tool Life (Holes) |

|---|---|---|

| Linear Drilling | 0.002″ | 120 |

| Helical Drilling | 0.0007″ | 210 |

Key Takeaway: For deep holes (>5xD), helical entry adds 5 seconds per hole but doubles tool life.

2. The “Williamsport Method” for Vibration Control

Local shops often retrofit older machines with:

– Active Dampers: Reduced chatter by 60% in a test on a Bridgeport Series I.

– Pre-Drilling Pilot Holes: Critical for diameters under 0.0625″.

Why Your Phone Call Matters: Local Expertise vs. Outsourcing

When you dial a precision drilling Williamsport PA phone number, you’re not just getting a machine shop—you’re tapping into:

– Material-Specific Knowledge: Familiarity with local supply chains (e.g., Lycoming County’s aerospace-grade aluminum suppliers).

– Quick Turnarounds: On-site tool grinding and CMM verification (saving 2–3 days vs. shipping to out-of-state shops).

Pro Tip: Ask potential vendors about their in-house metrology capabilities. A shop with a Zeiss Contura G2 (common in Williamsport) can measure while you wait.

The Future: AI and Adaptive Drilling

Williamsport is adopting machine learning-driven drilling (pioneered by local firms like Penn United Technologies). Sensors now adjust feeds/speeds in real-time, cutting energy use by 12%.

Final Advice: For your next project, prioritize shops that blend old-school craftsmanship with data-driven tools—the hallmark of Williamsport’s best.

Need a partner? Call a precision drilling expert in Williamsport, PA, today—and insist on seeing their last three inspection reports.