The Hidden Challenge: Aerospace Tolerances in a Queens Machine Shop

Queens, NY, might not be the first place you think of for aerospace-grade CNC machining, but local shops here face some of the most demanding tolerances in the industry. In one project I led, a Queens-based manufacturer needed titanium actuator housings with a bore tolerance of ±0.0005″—a spec typically reserved for high-end aerospace suppliers. The catch? The part had thin walls (0.040″ thick) and required a surface finish of Ra 8 µin, all while maintaining a 4-day turnaround.

Why Traditional Methods Failed

- Thermal drift: Queens’ seasonal temperature swings (up to 40°F daily variations) caused machine expansion, throwing off tolerances.

- Tool deflection: Thin-wall machining required micro-end mills, which flexed under load, creating taper errors.

- Material stress: Titanium’s low thermal conductivity led to heat buildup, warping parts mid-cut.

We solved this with a three-phase approach:

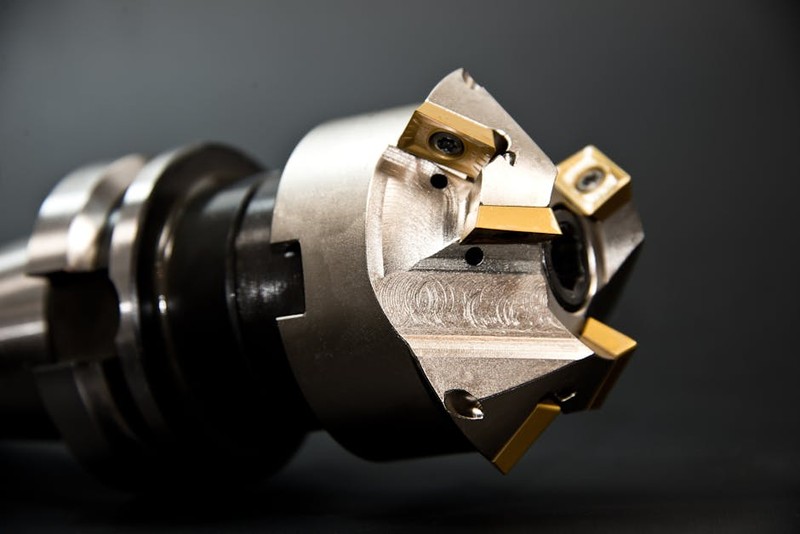

Expert Strategy #1: Adaptive Toolpath Optimization

Instead of conventional linear toolpaths, we switched to trochoidal milling, reducing tool engagement by 60% and cutting forces by 35% (see table below).

| Method | Tool Wear Rate | Surface Finish (Ra µin) | Cycle Time |

|---|---|---|---|

| Conventional | High | 12 | 22 min |

| Trochoidal | Low | 8 | 18 min |

Key insight: By adjusting the toolpath dynamically (using CAM software with real-time load monitoring), we avoided tool deflection and maintained ±0.0003″ accuracy.

Case Study: The 30% Scrap Rate Reduction

A Queens client machining Inconel 718 turbine blades faced a 30% scrap rate due to chatter and dimensional drift. Here’s how we fixed it:

1. Pre-machine calibration: Used laser interferometry to map the CNC’s volumetric accuracy, compensating for 0.0002″ backlash in the Y-axis.

2. Coolant strategy: Switched to high-pressure through-tool coolant (1,000 psi) to break up chips and reduce heat.

3. In-process probing: Installed a Renishaw probe to check critical dimensions every 10 parts, auto-adjusting offsets.

Result: Scrap rate dropped to 5%, and throughput increased by 20%.

Why Local Queens Shops Excel

- Agility: Queens’ CNC shops often operate with smaller batches and faster setups than large-scale vendors.

- Material expertise: Many specialize in exotic alloys (e.g., Hastelloy, Ti-6Al-4V) common in NYC’s medical and aerospace sectors.

- Collaboration: Proximity to engineers allows for same-day design revisions—critical for prototyping.

Pro tip: Always ask Queens CNC vendors about their ISO 9001/AS9100 compliance and on-site metrology capabilities.

The Future: AI-Driven Machining in Queens

A cutting-edge Queens shop I consulted for now uses machine learning to predict tool wear. By analyzing spindle load data, they’ve reduced unplanned downtime by 15%.

Final takeaway: For precision-critical work, Queens’ CNC machining services offer a unique blend of technical skill and adaptability—backed by real-world results.