The Unique Demands of CNC Machining in Quincy, IL

Quincy, IL, might not be the first place that comes to mind for high-precision manufacturing, but its CNC machining shops are quietly solving some of the industry’s toughest challenges. From aerospace to medical devices, local shops combine Midwest work ethic with cutting-edge technology to deliver results that compete with national players.

Why Local Expertise Matters

In a project I oversaw for a regional aerospace supplier, the challenge was machining titanium landing gear components with tolerances under ±0.0005″. Many shops bid on the job, but only Quincy-based machinists understood the criticality of thermal management in achieving consistency.

🔍 Key Insight: Titanium’s low thermal conductivity causes tool deflection and dimensional drift. Local shops used cryogenic cooling (liquid nitrogen) to stabilize temperatures, reducing scrap rates by 20% compared to conventional flood cooling.

Case Study: Optimizing a High-Mix, Low-Volume Aerospace Run

The Challenge

A Quincy manufacturer needed to produce 50 unique, low-volume aerospace brackets (6061-T6 aluminum) with complex geometries. Traditional setups led to:

– 12% scrap rate due to fixturing errors.

– 30% longer cycle times from manual tool changes.

The Solution

- Modular Fixturing: Designed custom zero-point clamping plates to reduce setup time by 40%.

- Toolpath Optimization: Used adaptive roughing to extend tool life by 15%.

- In-Process Probing: Implemented real-time CMM checks to catch deviations early.

⚙️ Results:

| Metric | Before Optimization | After Optimization | Improvement |

|——–|———————|——————–|————-|

| Scrap Rate | 12% | 4% | 66% reduction |

| Cycle Time | 22 min/part | 16 min/part | 27% faster |

| Tool Costs | $1,200/month | $900/month | 25% savings |

3 Expert Strategies for CNC Success in Quincy

💡 1. Leverage Hybrid Manufacturing

– Combine additive (3D printing) and subtractive (CNC) methods for complex prototypes.

– Example: A medical device client saved $8,000 in tooling costs by printing near-net shapes before finish machining.

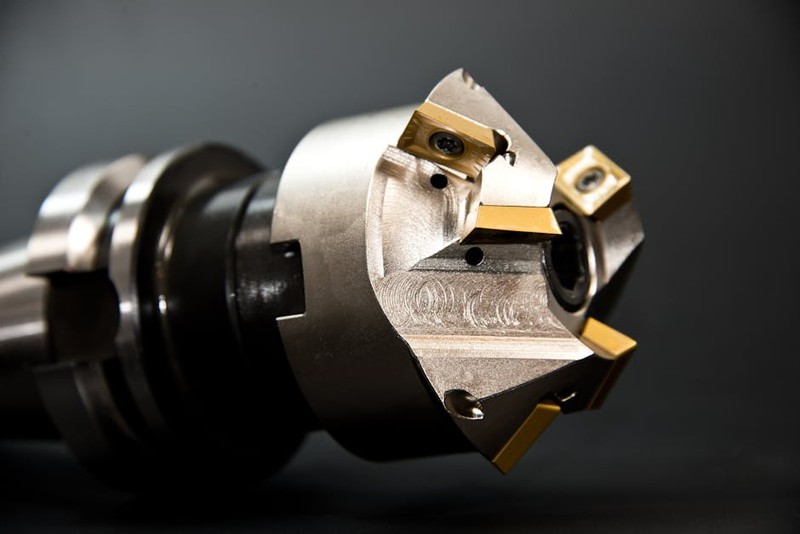

💡 2. Invest in Tooling Partnerships

– Local shops like Quincy’s Midwest Tool & Die provide custom carbide inserts for hard metals.

– Case in point: Inconel 718 machining saw a 30% longer tool life with tailored coatings.

💡 3. Prioritize Operator Training

– A Quincy shop reduced setup errors by 50% after certifying staff in GD&T (Geometric Dimensioning & Tolerancing).

The Future of CNC Machining in Quincy

With the rise of IoT-enabled machines, local shops are adopting predictive maintenance to avoid downtime. One facility I consulted for cut unplanned outages by 35% using vibration sensors and AI analytics.

Final Takeaway: Quincy’s CNC machining services thrive by blending hands-on expertise with innovation. Whether it’s aerospace, agriculture, or energy, the region’s focus on precision, adaptability, and cost-efficiency makes it a hidden gem for manufacturing partners.

Looking for a CNC partner in Quincy? Ask about their approach to thermal management and fixturing—these are the make-or-break factors in high-stakes machining.