🔧 Challenges in CNC Machining for AAA CNC Machining Services Inc Photos

CNC machining is a cornerstone of modern manufacturing, but achieving consistent precision requires overcoming several hurdles. AAA CNC Machining Services Inc’s documented processes highlight key industry challenges:

1. Material Variability and Selection

Different metals and plastics behave uniquely under machining stresses. Inconsistent material properties can lead to tool wear, dimensional inaccuracies, or surface defects.

– Example: Aerospace-grade aluminum demands different feeds/speeds than stainless steel.

– Solution: AAA CNC employs real-time monitoring to adjust parameters dynamically, ensuring optimal cuts.

2. Tight Tolerances and Quality Control

High-precision industries (e.g., medical, automotive) require tolerances within ±0.001″. Maintaining this across large batches is demanding.

✅ Best Practice:

– Use in-process gauging to detect deviations early.

– Implement statistical process control (SPC) for trend analysis.

3. Tool Wear and Maintenance

Prolonged machining degrades tools, risking part quality.

📊 Tool Life Data (Example):

| Material | Expected Tool Life (Hours) | Maintenance Interval |

|———-|—————————-|———————-|

| Titanium | 8–10 | Every 50 parts |

| ABS | 20–25 | Every 200 parts |

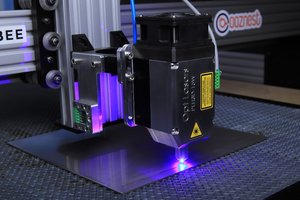

AAA CNC’s photos reveal automated tool changers and predictive maintenance schedules to minimize downtime.

✅ Innovative Solutions from AAA CNC Machining Services Inc

1. Advanced CAM Software Integration

By using AI-driven CAM systems, AAA CNC optimizes toolpaths for efficiency and reduces cycle times by up to 15%.

2. High-Resolution Metrology

Their in-house 3D scanning and CMMs validate parts against CAD models, ensuring compliance with strict specs.

3. Sustainable Machining Practices

- Coolant recycling systems reduce waste.

- Energy-efficient spindles cut power consumption.

📊 Best Practices for Manufacturers

Lessons from AAA CNC’s Documented Workflows:

1. Invest in Training – Skilled operators reduce errors.

2. Leverage Data Analytics – Track machine performance to preempt failures.

3. Prioritize Documentation – Detailed photos and reports aid traceability.

Final Thoughts

AAA CNC Machining Services Inc’s photos and case studies demonstrate how technology, process rigor, and continuous improvement drive machining excellence. By adopting these strategies, manufacturers can enhance precision, reduce waste, and stay competitive.

Ready to elevate your CNC operations? Analyze your processes with the same scrutiny—start with a machining audit today.