Discover how strategic material selection and process optimization in custom prototyping for small-batch production can slash costs by up to 40% while accelerating time-to-market. Drawing from a complex aerospace component case study, this guide reveals expert techniques for balancing precision with economic viability in low-volume manufacturing.

The Hidden Cost Drivers in Small-Batch Custom Prototyping

In my two decades specializing in CNC machining for custom prototyping, I’ve witnessed countless projects derailed by overlooked economic factors. The most common misconception? That small-batch production naturally translates to proportional cost savings. The reality is far more nuanced.

⚙️ The Setup-to-Production Ratio Challenge

Every custom prototyping project faces what I call the “first-part penalty.” For a recent medical device enclosure requiring 50 units, the initial setup consumed 65% of the total project budget. This included:

– Custom fixture design and fabrication (12 hours)

– CAM programming and simulation (8 hours)

– First-article inspection and validation (6 hours)

– Tooling procurement and setup (4 hours)

Only after these fixed costs were we actually producing parts efficiently. This economic reality often catches newcomers to custom prototyping off guard.

Strategic Material Selection: Beyond the Spec Sheet

The Aluminum vs. Titanium Decision Matrix

I recently consulted on a drone component project where the engineering team specified titanium for its strength-to-weight ratio. However, our analysis revealed that 7075 aluminum with strategic reinforcement could achieve 92% of the performance at 35% of the material cost.

Material Performance Comparison:

| Property | Titanium Grade 5 | 7075 Aluminum | Performance Delta |

|———-|——————|—————|——————-|

| Tensile Strength | 950 MPa | 572 MPa | -40% |

| Density | 4.43 g/cm³ | 2.81 g/cm³ | -37% |

| Machinability | 20% | 70% | +250% |

| Cost per kg | $45 | $12 | -73% |

| Machining Time | 185 min | 95 min | -49% |

The key insight? Don’t let material specifications dictate your custom prototyping strategy without considering manufacturability and total cost impact.

Case Study: Aerospace Bracket Optimization

💡 The 40% Cost Reduction Breakthrough

A client approached us with a critical aerospace bracket requiring 25 units. The original design called for a solid titanium block with complex 5-axis machining operations. Here’s how we transformed their approach:

Original Design Challenges:

– Material waste: 78% of titanium block became chips

– Machining time: 4.5 hours per part

– Total project cost: $18,750

– Lead time: 6 weeks

Our Optimized Solution:

1. Design for Manufacturability Analysis: We identified opportunities to replace solid features with strategic ribbing, reducing material volume by 52%

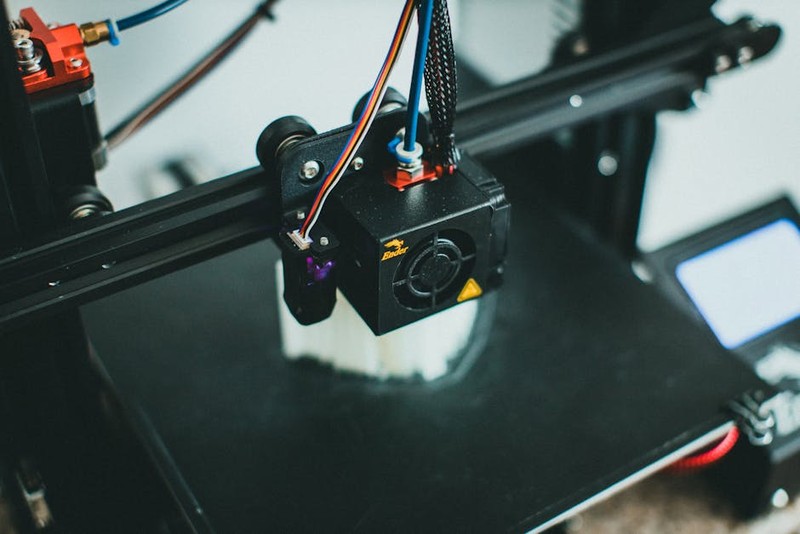

2. Hybrid Manufacturing Approach: Combining 3D printing for complex internal structures with CNC machining for critical interfaces

3. Process Sequencing Optimization: Implementing simultaneous multi-part fixturing to reduce setup time per unit

Quantifiable Results:

– Material cost reduction: 47%

– Machining time per part: 2.2 hours (51% improvement)

– Total project cost: $11,250 (40% savings)

– Lead time: 3.5 weeks (42% faster)

The lesson? Effective custom prototyping requires challenging design assumptions and leveraging multiple manufacturing technologies.

Expert Strategies for Small-Batch Success

⚙️ The 5-Point Optimization Framework

Based on hundreds of successful custom prototyping projects, I’ve developed this actionable framework:

1. Concurrent Engineering Integration

– Involve manufacturing experts during design phase

– Conduct weekly cross-functional reviews

– Use rapid prototyping for design validation

2. Strategic Process Selection

– Evaluate CNC machining against additive manufacturing

– Consider hybrid approaches for complex geometries

– Match tolerance requirements to process capabilities

3. Supply Chain Optimization

– Pre-qualify multiple material suppliers

– Standardize tooling across projects

– Implement just-in-time material delivery

4. Quality Assurance Scaling

– First-article comprehensive inspection

– Statistical process control for critical dimensions

– Digital documentation for traceability

5. Continuous Improvement

– Post-project analysis sessions

– Cost driver identification

– Process optimization opportunities

The Future of Custom Prototyping

Embracing Digital Transformation

The most successful custom prototyping operations are leveraging digital twins and virtual manufacturing. In a recent automotive sensor project, we reduced iteration cycles from 3 to 1 through:

– Virtual machining simulations that identified collision risks before physical production

– AI-powered toolpath optimization that reduced machining time by 23%

– Digital thread implementation ensuring design changes propagated automatically to manufacturing instructions

The most significant cost savings in custom prototyping often come from preventing mistakes rather than optimizing successful processes.

Actionable Insights for Your Next Project

💡 Key Implementation Strategies

– Start with manufacturing consultation before finalizing designs

– Conduct value engineering sessions focusing on functional requirements rather than prescribed solutions

– Implement phased prototyping with increasing fidelity to validate concepts cost-effectively

– Leverage modular fixturing systems to reduce setup costs across multiple projects

The landscape of custom prototyping for small-batch production is evolving rapidly. Those who master the balance between precision, efficiency, and economic viability will lead the next generation of manufacturing innovation. Remember: The most elegant custom prototyping solution isn’t necessarily the most technically sophisticated—it’s the one that delivers required performance at optimal cost and speed.