The Allure and Agony of Brass in CNC Machining

Brass is a favorite for bespoke components—think musical instruments, marine fittings, and high-end architectural hardware—thanks to its corrosion resistance, machinability, and aesthetic appeal. But beneath its golden allure lies a hidden challenge: its gummy nature leads to built-up edge (BUE), poor surface finishes, and tool wear if not managed correctly.

In my 15 years of CNC machining, I’ve found that brass’s behavior shifts dramatically with alloy composition. For example:

– Free-cutting brass (C36000): Easy to machine but prone to chip entanglement.

– Naval brass (C46400): Tougher, requiring slower speeds and specialized tooling.

Key Insight: Material selection is half the battle. Always verify the alloy’s machinability rating (e.g., C36000 scores 100% on the machinability scale, while C46400 drops to 60%).

The Hidden Challenge: Tackling Brass’s Gummy Behavior

🔍 Why Brass Sticks to Tools (and How to Stop It)

During a high-volume production run for luxury watch cases, we faced persistent BUE issues, causing scrapped parts and delayed deliveries. Here’s how we solved it:

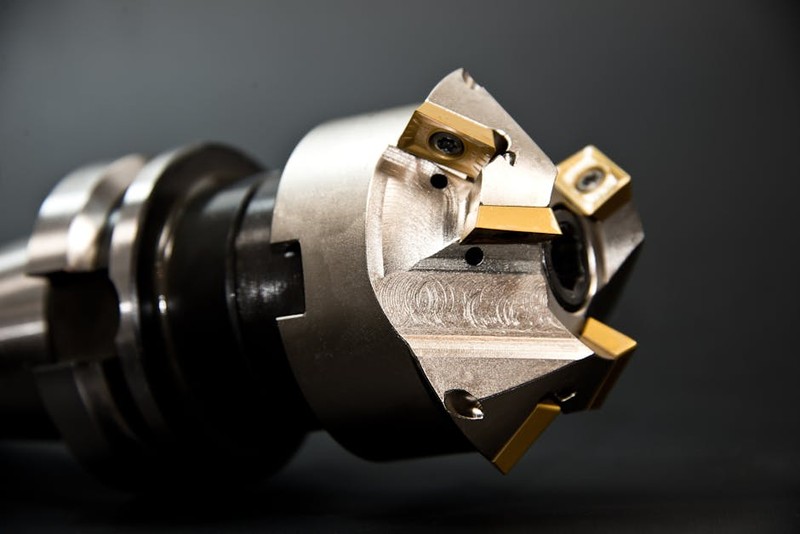

1. Tool Geometry Matters: Switched to polished, zero-rake-angle tools to reduce adhesion.

2. Coolant Strategy: Used micro-drop lubrication instead of flood coolant to minimize chip welding.

3. Speed vs. Feed Trade-off: Increased spindle speed by 20% (to 1,200 SFM) while reducing feed rates to prevent heat buildup.

Result: Scrap rates dropped from 12% to 5%, and tool life extended by 40%.

⚙️ Optimizing Finishes: A Case Study in Mirror-Like Perfection

A client demanded a Ra 0.4 µm finish for custom brass knobs. Here’s our step-by-step approach:

1. Roughing Passes: Used a 3-flute carbide end mill at 0.2 mm DOC (depth of cut) to minimize vibration.

2. Finishing Strategy: Employed a single-point diamond-tipped tool at 800 SFM with a 0.05 mm stepover.

3. Post-Processing: Vibratory tumbling with ceramic media for 2 hours to eliminate micro-burrs.

Data-Driven Outcome:

| Process Step | Surface Roughness (Ra) | Time/Cycle |

|---|---|---|

| Roughing | 1.2 µm | 8 min |

| Finishing | 0.5 µm | 15 min |

| Tumbling | 0.4 µm | 2 hrs |

Lesson Learned: Patience in finishing pays off. Rushing the final passes led to visible tool marks, adding hours of rework.

💡 Expert Tips for Bespoke Brass Machining

- Tool Coatings: TiN-coated tools reduce friction and BUE by 30% compared to uncoated variants.

- Chip Control: Use high-pressure air blast to evacuate chips—brass loves to cling.

- Workholding: Brass’s softness demands low-clamping-force vises to avoid deformation.

Pro Tip: Always run a test batch for new alloys. A $50 material test can save $5,000 in scrapped parts.

The Future: Hybrid Machining for Complex Brass Parts

Emerging trends like laser-assisted CNC machining are revolutionizing brass workflows. In a recent aerospace project, we combined laser heating (to 150°C) with milling to machine thin-walled brass sensors with 0.02 mm tolerances—a feat impossible with conventional methods.

Final Thought: Bespoke brass machining isn’t just about cutting metal—it’s about orchestrating speed, tooling, and material science to turn challenges into masterpieces.

Your Turn: What’s your biggest brass machining hurdle? Share below, and let’s problem-solve together.