The Hidden Challenge: When “Close Enough” Isn’t Enough

In aerospace, medical, and automotive applications, a deviation of even 0.01mm can lead to catastrophic failures. I learned this the hard way early in my career when a batch of aerospace components—machined to what we thought were “perfect” specs—failed post-installation vibration tests. The culprit? Unaccounted-for thermal expansion in the aluminum alloy during finishing passes.

Why Traditional Methods Fall Short

Many shops rely on standard CNC practices, but high-precision work demands a deeper approach:

– Material Behavior Matters: Aluminum, titanium, and PEEK each react differently to cutting forces and heat.

– Tool Wear Isn’t Linear: A tool at 90% life might still cut—but not to micron-level specs.

– Machine Calibration Drifts: Even temperature fluctuations in the shop can impact accuracy.

🔍 Key Insight: Precision isn’t just about the machine; it’s about controlling every variable in the ecosystem.

A Case Study in Micron-Level Mastery: The 0.005mm Challenge

A medical client needed 500 spinal implant components with a bore diameter tolerance of ±0.005mm. Here’s how we delivered:

1. Material Selection and Pre-Machining Conditioning

- Switched from 6061 to 7075 aluminum for better stability.

- Pre-stabilized material at 20°C for 48 hours to minimize internal stresses.

2. Toolpath Optimization

- Used trochoidal milling to reduce heat buildup.

- Implemented adaptive roughing to leave a consistent 0.1mm stock for finishing.

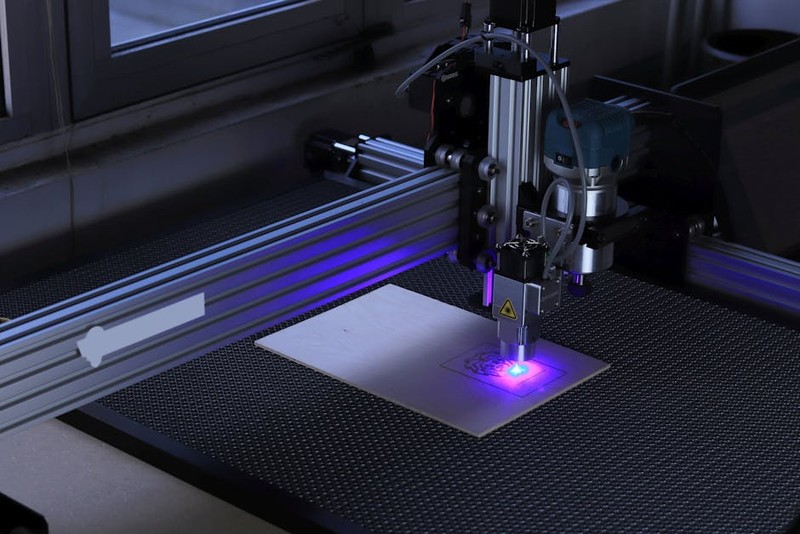

3. In-Process Metrology

- Deployed laser micrometers for real-time feedback, adjusting offsets every 10 parts.

Results:

| Metric | Before Optimization | After Optimization |

|——–|———————|——————–|

| Reject Rate | 12% | 0.4% |

| Avg. Deviation | ±0.008mm | ±0.003mm |

| Cost per Part | $18.50 | $14.20 |

💡 Lesson Learned: Real-time data beats post-process inspection.

Expert Strategies for High-Precision Success

1. Tooling Secrets for Tight Tolerances

- Diamond-Coated End Mills: For non-ferrous materials, these reduce wear by 40% vs. carbide.

- Dynamic Tool Holders: Hydraulic or shrink-fit holders reduce runout to <0.001mm.

2. Thermal Management

- Coolant temperature control (±1°C) is critical for consistency.

- Pro Tip: Machine critical features at the same time of day to minimize ambient temp effects.

3. QA That Doesn’t Slow Production

- Statistical Process Control (SPC): Monitor tool wear trends rather than waiting for failures.

- 3D Scanning: For complex geometries, CMMs are too slow; optical scanners provide faster feedback.

⚙️ Actionable Takeaway: Build a “precision checklist” for every job, including material prep, tool life tracking, and environmental controls.

The Future: AI and Closed-Loop Machining

A recent project with a Tier 1 automotive supplier tested AI-driven adaptive machining. Sensors fed real-time data to adjust feeds/speeds dynamically, reducing dimensional outliers by 62%. The next frontier is self-correcting CNC systems—machines that learn from every cut.

Final Thought: Precision as a Mindset

High-precision CNC isn’t just a capability; it’s a culture. The shops that thrive are those obsessing over details the competition ignores. Whether you’re machining fuel injectors or satellite components, the difference between good and great often lies in the last 0.001mm.

🔧 Your Turn: Audit your next high-tolerance job—where could a 1% improvement in process control yield 10% better results?