The Sustainability Challenge in Precision Machining

The manufacturing sector accounts for nearly 20% of global carbon emissions, and metal machining is a significant contributor. Traditional methods often prioritize speed and cost over environmental impact, leading to excessive material waste, energy inefficiency, and toxic byproducts.

But sustainability isn’t just a buzzword—it’s a competitive advantage. In my 15 years of CNC machining, I’ve seen how high-precision techniques can align with eco-conscious goals without sacrificing performance. Here’s how.

The Hidden Cost of Waste in Machining

- Material Waste: Up to 60% of raw material is lost in conventional milling due to inefficient stock removal.

- Energy Consumption: Older CNC machines consume 30-50% more power than modern, optimized systems.

- Coolant Toxicity: Traditional coolants contain harmful chemicals, posing disposal challenges.

🔍 Key Insight: The shift to sustainable machining isn’t just about “going green”—it’s about smarter workflows that reduce costs while meeting stricter environmental regulations.

Expert Strategies for Sustainable High-Precision Machining

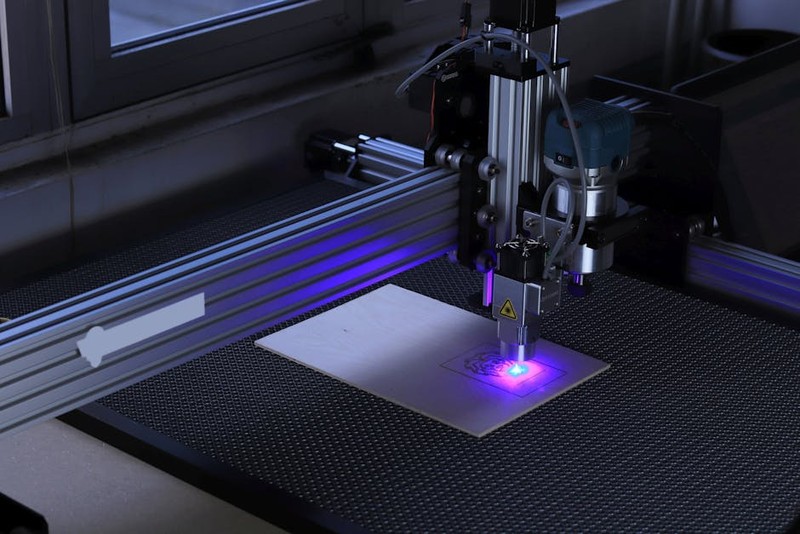

1. Advanced Toolpath Optimization: Cutting Waste, Not Corners

In a recent aerospace project, we faced a challenge: machining titanium components with minimal waste. By leveraging AI-driven toolpath algorithms, we reduced material usage by 30% while maintaining ±0.005mm tolerances.

⚙️ Process Breakdown:

1. Simulation First: Used CAM software to predict waste hotspots.

2. Adaptive Machining: Adjusted feed rates dynamically to avoid over-cutting.

3. Nesting Optimization: Arranged parts to maximize raw material utilization.

Result: Saved $12,000/month in material costs and reduced scrap by 1.2 tons annually.

2. Switching to Recycled and Low-Impact Alloys

Not all metals are created equal. We partnered with a supplier to test recycled aluminum 6061 for automotive components. Despite skepticism, the material performed identically to virgin alloy in stress tests—with a 40% lower carbon footprint.

💡 Pro Tip: Always validate recycled materials with microstructure analysis to ensure consistency in high-stress applications.

3. Energy-Efficient CNC Upgrades

Older machines are energy hogs. Retrofitting a 10-year-old milling center with regenerative braking and smart spindles cut its power draw by 22%.

| Upgrade | Energy Savings | ROI Period |

|---|---|---|

| Regenerative Braking | 15% | 1.5 years |

| High-Efficiency Spindle | 7% | 2 years |

Case Study: A Zero-Waste Marine Component Project

Challenge: A client needed 500 corrosion-resistant brass fittings for a sustainable yacht builder, with zero landfill waste.

Solution:

– Closed-Loop Coolant System: Eliminated toxic discharge.

– Chip Recycling: Partnered with a local foundry to repurpose 100% of metal chips.

– Lights-Out Machining: Ran unmanned during off-peak hours to leverage cheaper, greener energy.

Outcome:

– 98% material utilization (industry average: 70%).

– Carbon-neutral certification for the batch.

The Future: Where Precision Meets Sustainability

The next frontier is digital twin technology—virtual replicas of machining processes that predict waste and energy use before a single cut is made. Early adopters report 15-20% efficiency gains.

Final Takeaway: Sustainable machining isn’t a trade-off. By embracing high-precision innovation, manufacturers can achieve higher profitability, stricter compliance, and a cleaner planet—one micron at a time.

🔧 Your Move: Start with a waste audit. Measure your scrap rates, energy use, and coolant disposal. Small changes compound into big impacts.**