Why Choosing Local CNC Milling Services Matters

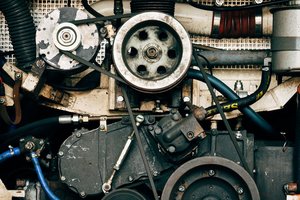

In today’s fast-paced manufacturing landscape, proximity and precision are critical. Partnering with a trusted CNC milling service near me ensures faster lead times, easier collaboration, and better quality control—factors that directly impact production efficiency.

But how do you identify the best provider for your needs? Let’s break down the challenges, solutions, and key considerations when selecting a CNC milling partner.

🔧 Challenges in CNC Milling and How to Overcome Them

1. Material Variability and Machining Precision

Different materials (aluminum, titanium, plastics) behave uniquely under machining stresses. Inconsistent material properties can lead to:

– Tool wear and breakage

– Dimensional inaccuracies

– Surface finish defects

✅ Solution:

– Work with providers that perform material testing before production.

– Opt for shops with multi-axis CNC machines for complex geometries.

– Verify their expertise in high-tolerance machining (e.g., ±0.001″ tolerances).

2. Balancing Cost and Quality

Low-cost providers may compromise on:

– Machine calibration

– Skilled operator expertise

– Post-processing (deburring, anodizing, etc.)

✅ Solution:

– Request sample parts to evaluate quality firsthand.

– Compare value-added services (e.g., finishing, assembly) rather than just base pricing.

– Look for certifications (ISO 9001, AS9100) as proof of quality standards.

3. Lead Time vs. Production Demand

Delays in CNC milling can disrupt entire supply chains. Common bottlenecks include:

– Machine backlog

– Inefficient workflow management

– Late-stage design changes

✅ Solution:

– Choose a local provider with quick-turnaround capabilities.

– Leverage DFM (Design for Manufacturing) feedback early in the process.

– Confirm their capacity for both prototyping and large-scale production.

📊 Key Factors When Evaluating CNC Milling Services Near Me

| Criteria | What to Look For |

|---|---|

| Machining Technology | 3-axis, 5-axis, or Swiss CNC capabilities |

| Material Expertise | Experience with alloys, composites, plastics |

| Quality Assurance | In-house CMM inspection, ISO certifications |

| Lead Time | Rush options, average turnaround time |

| Customer Support | Responsive communication, project management |

✅ Best Practices for Partnering with a CNC Milling Service

- Define Your Requirements Clearly

- Provide detailed CAD files and material specs.

- Specify tolerances, surface finishes, and post-processing needs.

- Visit the Facility (If Possible)

- Assess their equipment, cleanliness, and workflow efficiency.

- Prioritize Long-Term Collaboration

- A reliable partner should scale with your production demands.

Final Thoughts: Making the Right Choice

Finding the best CNC milling services near me isn’t just about proximity—it’s about precision, reliability, and partnership. By focusing on material expertise, quality control, and responsive service, you can streamline production and reduce costly delays.

Need a trusted CNC milling partner? [Contact us] today to discuss your project requirements and get a precision-machined solution tailored to your needs.