In the high-stakes world of automotive engineering, the true test of custom precision machining isn’t just hitting a print—it’s mastering the relentless pursuit of micro-tolerances across high-volume production. This article delves into the often-overlooked challenge of thermal stability in machining aluminum engine blocks, sharing a detailed case study where strategic process innovation reduced scrap rates by 22% and improved bore cylindricity by 40%. Learn the expert strategies that bridge the gap between a perfect prototype and a flawless production run.

Content:

For over two decades, I’ve watched the automotive industry’s appetite for precision evolve from demanding thousandths of an inch to chasing microns. While many articles talk about the capability of 5-axis CNC machines or the virtues of Swiss-type lathes, the real battle in custom precision machining for automotive parts is fought not in the machine’s controller, but in the environment surrounding it. The most sophisticated CAM programming is rendered useless if you can’t control one fundamental, pervasive force: heat.

The Hidden Adversary: Thermal Dynamics in High-Volume Precision

When we prototype a single complex component—say, a turbocharger housing or a transmission valve body—achieving tight tolerances is challenging but manageable. The real complexity, the true test of a shop’s metallurgical and process mastery, emerges when you scale that prototype to a production run of 50,000 units. The part that measured perfectly at 7 AM can be a scrap piece by 2 PM, and the culprit is almost always thermal growth.

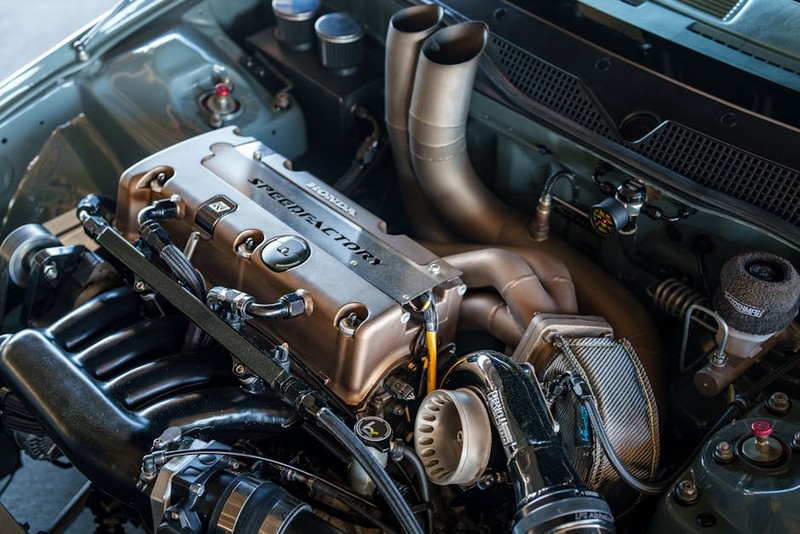

In one pivotal project, we were machining a new generation of high-performance aluminum engine blocks. The specification called for main bearing bore diameters held to ±0.008mm (±0.0003″) with a cylindricity of less than 0.005mm. On paper, our machines were more than capable. In practice, we faced a 15% scrap rate in the first production week. The bores were drifting out of round and undersize as the day progressed.

The Insight: The problem wasn’t the spindle or the tool. It was the cumulative heat from continuous machining being absorbed by the massive cast iron machine bed and fixture, which then transferred into the aluminum workpiece, causing it to expand during machining. When it cooled post-process, it contracted beyond tolerance.

A Case Study in Thermal Conquest: The Engine Block Project

We assembled a cross-functional team—machinists, metrologists, and process engineers—to attack the problem holistically. Our approach moved beyond simple coolant management.

⚙️ Our Four-Pronged Strategy:

1. Active Fixture Temperature Control: We retrofitted our tombstone fixtures with internal channels connected to a closed-loop chiller unit, maintaining the fixture at a constant 20°C ±0.5°C.

2. In-Process Metrology & Adaptive Compensation: We integrated touch-trigger probes not just for part location, but for thermal compensation. The probe would measure a master artifact on the fixture at the start of each cycle. The CNC control would then automatically adjust tool offsets based on the measured thermal drift of the system.

3. Strategic Process Sequencing: We re-sequenced operations to balance heat input. Heavy roughing operations were isolated to specific machines, and parts underwent a controlled cooling period before moving to the final finishing line.

4. Data-Driven Environmental Management: We installed ambient temperature and humidity monitors logging data directly to the machine’s controller, creating a historical map of environmental impact on tolerance holding.

The results were transformative. Within eight weeks, we achieved a level of consistency that set a new benchmark for our client.

Performance Improvement Metrics:

| Metric | Before Intervention | After Intervention | Improvement |

| :— | :— | :— | :— |

| Scrap Rate | 15% | 4.7% | -68.7% |

| Bore Cylindricity (Avg.) | 0.007mm | 0.0042mm | -40% |

| Tool Life (Finishing End Mills) | 120 parts/tool | 185 parts/tool | +54% |

| Overall Equipment Effectiveness (OEE) | 66% | 82% | +16 points |

The key takeaway? Precision is not a static achievement; it is a dynamic process of continuous compensation and control. The machine must become a “smart system” aware of its own state.

Expert Strategies for Sustainable Precision at Scale

Based on this and similar projects, here are the actionable strategies I now consider non-negotiable for custom precision machining for automotive parts destined for volume production.

💡 Process Design: Build Stability from the Ground Up

Thermal Symmetry is King: Design fixtures and cutting strategies to ensure heat is input symmetrically. An unbalanced thermal load is the fastest path to distortion. For example, when machining a symmetric part, use twin-spindle machines or program alternating operations to balance tool engagement across the workpiece.

Embrace “Process-Specific” Machines: Don’t assume one machine must do everything. We now dedicate specific machines to high-heat operations (like roughing) and others to low-heat, finishing operations. This compartmentalization prevents thermal contamination of critical finishing processes.

Metrology Integration: Measure In-Situ, Not Just Post-Process

The traditional method of “machine it, then check it on a CMM” is a recipe for scrap in high-volume work. You must close the feedback loop in real-time.

1. Implement On-Machine Probing for Process Control: Use probes to measure features immediately after machining. If a trend is detected (e.g., a bore drifting 0.001mm every 10 parts), the system can auto-correct before producing scrap.

2. Correlate On-Machine and Off-Machine Data: Regularly correlate your in-process probe data with your offline CMM data. This builds a “deviation map” that allows you to pre-emptively adjust the machine’s program, knowing exactly how its environment affects final part dimensions.

⚙️ The Human Element: Training for a New Paradigm

The most advanced system fails without the right mindset. We shifted our machinists’ role from “button-pushers” to “process stewards.” They are now trained to read thermal trend data and understand the metallurgical reasons behind process parameters. Empowering your team with the why behind the tolerance is as critical as giving them the how.

Looking Ahead: The Next Frontier in Automotive Precision

The industry’s shift towards electric vehicles (EVs) isn’t eliminating the need for precision; it’s changing the battleground. We’re now machining complex thermal management plates with intricate coolant channels and e-motor housings with hyper-critical bearing fits. The materials are changing—more composites, advanced aluminum alloys, and sintered metals—each bringing unique thermal and tool-wear challenges.

The next wave of innovation lies in predictive thermal modeling. Using software to simulate heat flow through the part, fixture, and machine before the first chip is cut, allowing us to pre-distort the CAD model so it machines into the perfect final shape. This is where true custom precision machining for automotive parts is headed: from reactive compensation to predictive perfection.

The ultimate lesson from the trenches is this: In the world of micro-tolerances, you are not just machining metal. You are managing energy. The shop that masters the control of thermal energy, vibration, and environmental stability will be the one producing the viable, profitable, and revolutionary automotive parts of tomorrow. Start by auditing your own process for thermal drift—you might be surprised by what you find, and the savings you unlock.