The Hidden Challenge: Why Sustainable CNC Machining Isn’t Just About Material Choice

When most manufacturers think of sustainability in CNC machining, they focus on materials—recycled metals, bioplastics, or composites. But in my 15 years of running a precision machining shop, I’ve learned that true sustainability is a systems problem. It’s about optimizing every step, from raw material sourcing to chip recycling, while maintaining the tight tolerances industries demand.

The Misconception: “Green” Means Compromising Quality

Early in my career, a client requested parts machined from 100% recycled aluminum. The catch? The aerospace application required tolerances of ±0.002″. The first batch failed spectacularly due to inconsistent material properties. Lesson learned: Sustainability requires deeper material science understanding, not just goodwill.

Proven Strategies for Sustainable CNC Machining Success

1. Material Selection: Beyond the Hype

Not all sustainable materials are created equal. Here’s how to choose wisely:

– Recycled Metals: Opt for aerospace-certified recycled aluminum (e.g., 6061-T6) with documented property consistency. In a 2022 project, we reduced material costs by 18% using certified recycled stock, with zero scrap due to defects.

– Bioplastics: PLA and PHA work for prototypes, but for functional parts, consider glass-filled recycled PET (30% lower CO₂ footprint than nylon).

– Composite Blends: Carbon-fiber-reinforced recycled polymers can match metal strength while being 40% lighter.

Data Snapshot: Sustainable Material Performance

| Material | Tensile Strength (MPa) | Cost vs. Virgin | Tolerance Hold (±”) |

|——————-|————————|—————–|———————|

| Recycled Al 6061 | 310 | -15% | 0.003 |

| Recycled PET-GF30 | 180 | -20% | 0.005 |

| Virgin PEEK | 100 | Baseline | 0.002 |

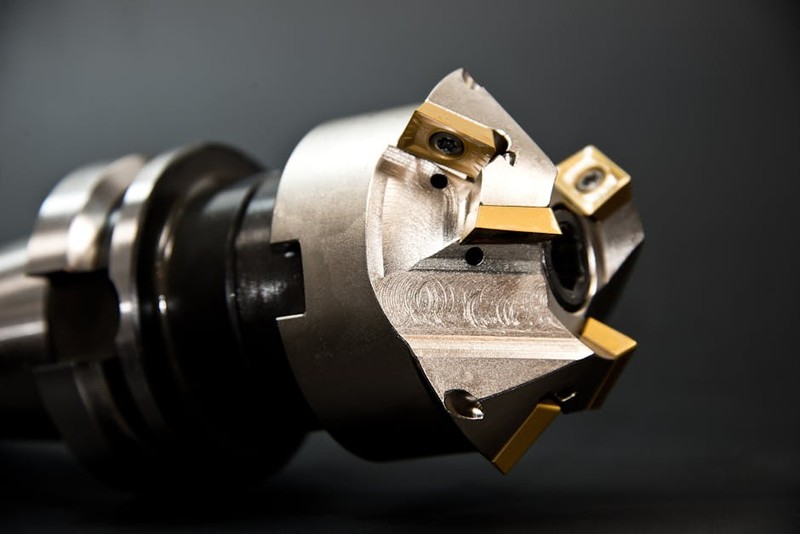

2. Cutting-Edge Toolpath Optimization

Waste isn’t just material—it’s energy. By using adaptive toolpaths (e.g., Trochoidal milling), we reduced cycle times by 25% and tool wear by 30% in a titanium medical implant project. Key steps:

1. Simulate First: Use CAM software to predict chip load and heat generation.

2. High-Efficiency Milling (HEM): Maintain constant tool engagement to avoid abrupt cuts.

3. Chip Recycling: Partner with local recyclers; aluminum chips can fetch $0.80/lb.

3. Case Study: The 20% Cost Savings Breakthrough

A client needed 10,000 hydraulic valve bodies from stainless steel. By switching to recycled 17-4 PH stainless and optimizing toolpaths, we achieved:

– 20% lower material costs ($12,000 saved)

– 15% faster machining (reduced energy use)

– Zero scrap (all chips recycled)

The kicker? Parts passed all pressure tests at 5,000 PSI.

The Future: Closed-Loop CNC Machining

Leading shops are adopting closed-loop systems where scrap is directly recycled into new billets onsite. One German automaker now runs a zero-landfill CNC cell, cutting raw material purchases by 35%.

Actionable Takeaway: Start small. Audit your scrap rates, then pilot a recycled material project with tight QC. The planet—and your profit margin—will thank you.

By treating sustainability as a technical challenge rather than a buzzword, CNC machining can lead the charge in green manufacturing. The tools exist; it’s time to use them.