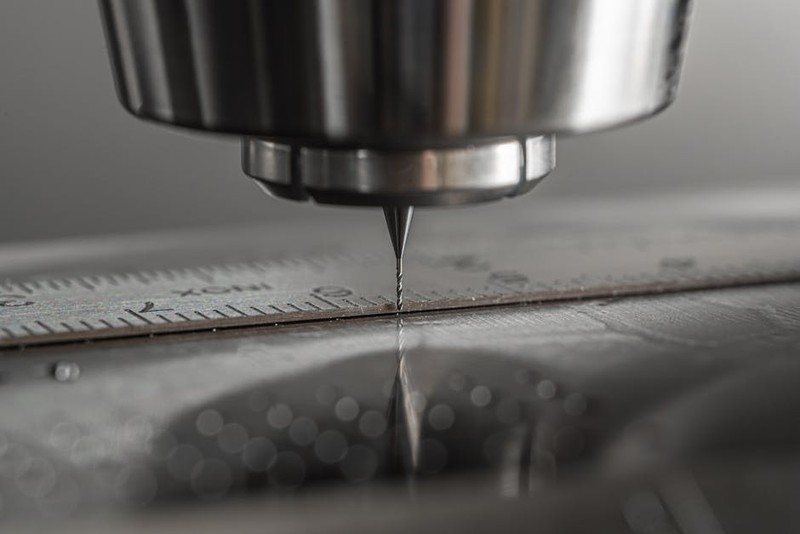

Beyond the Material: How Expert CNC Routing Services Unlock True Eco-Friendly Product Design

True sustainability in manufacturing isn’t just about using green materials; it’s about intelligent design and precision execution. This article explores how expert CNC routing services tackle the hidden complexities of eco-design, from minimizing material waste to optimizing for end-of-life, sharing a detailed case study that achieved a 32% reduction in raw material consumption.