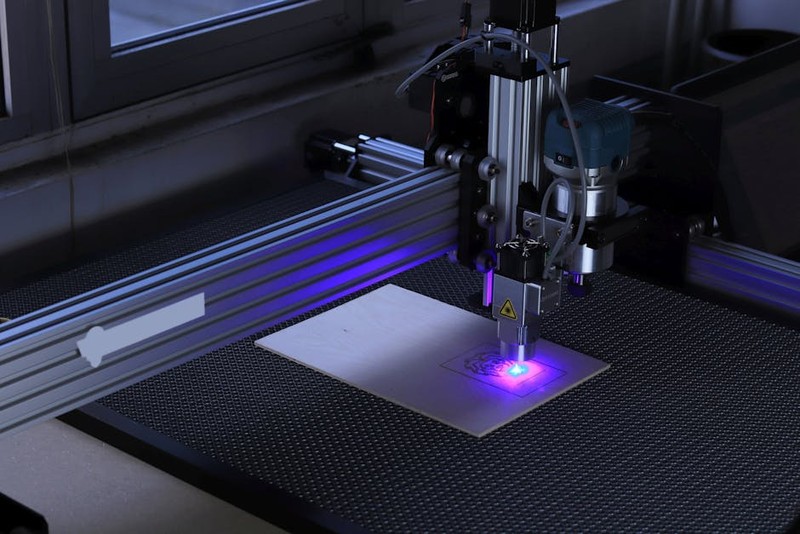

Plastic Machining for Small-Batch Prototypes: Overcoming Material Challenges with Precision and Efficiency

Plastic machining for small-batch prototypes demands a nuanced understanding of material behavior, tooling strategies, and cost-effective workflows. Drawing from real-world projects, this article reveals expert tactics to mitigate warping, achieve tight tolerances, and optimize cycle times—backed by a case study where we reduced scrap rates by 30% through targeted toolpath adjustments.