True high-precision CNC machining isn’t just about hitting a tolerance on a drawing. It’s a holistic battle against thermal drift, material memory, and cumulative error. Drawing from decades of field experience, this article reveals the critical, often-overlooked factors that separate good parts from perfect ones, backed by a detailed case study on a mission-critical aerospace component.

The Illusion of the Print: When “In Tolerance” Isn’t Enough

For over two decades in this field, I’ve seen a common misconception: a part that measures within its specified tolerances on the CMM is a success. In many applications, that’s true. But in true high-precision industrial realms—aerospace, medical implants, advanced optics, and defense—this is where the real work begins. The print is merely the starting gate.

The hidden challenge isn’t the machine’s ability to move to a coordinate; it’s the machine’s, and the material’s, ability to stay there. We’re fighting a multi-front war against:

Thermal Dynamics: A shop floor that fluctuates by 4°C can cause a 40-micron drift in a large steel frame over its length. Spindle growth from friction can be another 10-15 microns.

Material Stress: Metals have memory. The internal stresses locked in from forging or rolling are released as you cut, causing the part to “move” unpredictably after it’s unclamped.

Cumulative Error: A 2-micron error on one bore, compounded by a 3-micron error on a mating surface 300mm away, results in a functional failure, even though each feature is “in spec.”

I recall a project for a satellite gimbal mechanism where every feature was within ±0.005″. On paper, it was perfect. In assembly, it bound up. The culprit? Not a single out-of-spec dimension, but a non-specified form error on a critical bearing seat—a slight lobing that the CMM’s best-fit circle analysis missed. The part passed QC but failed its function. That lesson cost us six weeks and reshaped our entire philosophy.

The Expert’s Playbook: A Systems Approach to Precision

Achieving repeatable, industrial-grade precision requires moving beyond the machine tool. It demands a controlled ecosystem. Here’s the framework we’ve developed through hard-won experience.

⚙️ Process Foundation: Stability Before Speed

The first rule is to remove variables. You cannot compensate for a shaky foundation.

1. Thermal Management is Non-Negotiable: We maintain a 20°C ±0.5°C environment for high-precision work. Machines are equipped with spindle chillers and, for the most critical work, coolant temperature control systems. The machine must be thermally saturated before the first cut. We run a warm-up routine for at least 90 minutes, cycling the spindle and axes.

2. Strategic Stock Removal: We treat roughing as a stress-relief operation. For high-stress materials like 4140 steel or 7075 aluminum, we’ll rough, then unclamp and stress relieve (often a thermal cycle), then re-fixture for semi-finishing. This adds a step but eliminates spring-back during final cuts.

3. The Fixturing Mindset: The part is only as stable as its connection to the machine. We design fixtures for minimal, consistent clamping force and maximum rigidity. For thin-walled components, we often use low-melt alloys or vacuum chucks to distribute holding force evenly.

A Case Study in Holistic Precision: The Titanium Orthopedic Implant

A client needed a load-bearing spinal fusion cage from Ti-6Al-4V ELI (medical-grade titanium). The challenge was a series of 0.8mm wide bone-in-growth channels with a profile tolerance of ±0.012mm and a surface finish requirement of Ra 0.4µm. The part also had to be completely burr-free.

The Initial Failure: Using a standard 4-flute carbide end mill with flood coolant, we achieved the width but with inconsistent surface finish and micro-burrs at the channel intersections. Deburring was impossible without altering the critical profile.

The Expert Solution:

Tooling Innovation: We switched to a single-flute, polished solid carbide end mill specifically designed for titanium. The single flute allowed for better chip evacuation, critical in a deep, narrow slot.

Process Change: We abandoned flood coolant for high-pressure, through-tool Minimum Quantity Lubrication (MQL). This provided lubrication at the cutting edge without thermally shocking the part or tool, which was causing micro-fractures and burrs.

Path Optimization: We used a trochoidal milling path for the channels, maintaining a constant chip load and radial engagement. This reduced heat and tool deflection.

The Quantifiable Result:

| Metric | Initial Process | Optimized Process | Improvement |

| :— | :— | :— | :— |

| Profile Tolerance Consistency | ±0.018mm | ±0.008mm | 56% More Consistent |

| Surface Finish (Ra) | 0.6 – 0.8µm | 0.35 – 0.4µm | Achieved Spec |

| Tool Life per Part | 1.5 parts | 4 parts | 167% Increase |

| Post-Processing Time | 25 min (deburring) | 0 min | 100% Reduction |

The key takeaway wasn’t just a better toolpath; it was understanding that in high-precision work, the interaction between tool geometry, material behavior, and heat management is a single, interconnected system.

💡 Actionable Insights for Your Next Project

Based on lessons from the field, here is your checklist when evaluating a high-precision CNC machining service:

Ask About Their Thermal Protocol: Don’t just ask about machine accuracy. Ask, “What is your shop temperature control spec and machine warm-up procedure?”

Discuss Stress Relief as a Process Step: For critical components, propose a rough-stress relief-finish sequence. The added cost is insurance against scrap.

Specify More Than Dimensional Tolerances: Call out form, orientation, and location tolerances (flatness, perpendicularity, true position) on your drawing. This controls the relationship between features, which is often more critical than their individual sizes.

Request First-Article Data, Not Just a Pass/Fail: A reputable shop will provide a full first-article inspection report with actual measured values, not just checkmarks. This data trend is invaluable.

The Future is Measured in Nanometers

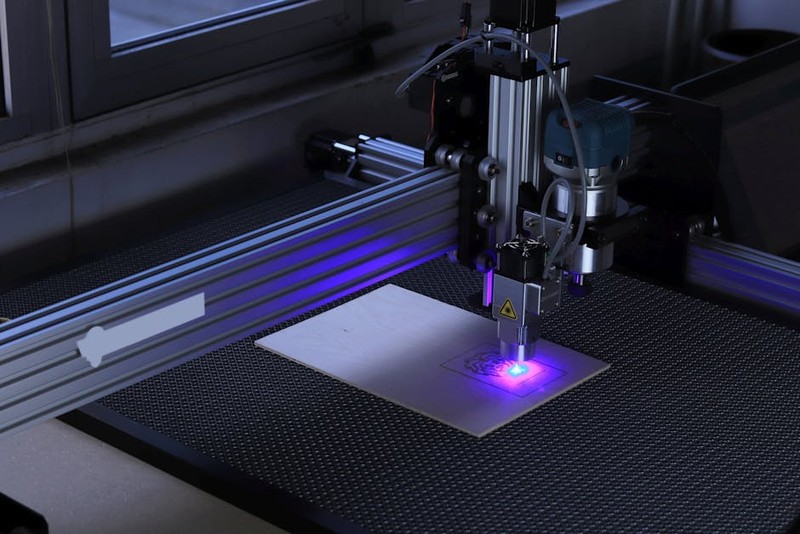

The frontier of high-precision CNC machining is already pushing into sub-micron and nanometer-level control, driven by advancements in metrology and machine intelligence. In-situ probing and laser tool setters now provide real-time compensation. The next leap is predictive compensation, where the machine learns its own thermal and mechanical behavior patterns and adjusts proactively.

The journey from a block of material to a perfect part is one of constant vigilance. It’s a blend of cutting-edge technology and timeless craftsmanship—the programmer’s code, the machinist’s intuition, and the metrologist’s relentless pursuit of truth. In the world of industrial applications, where failure is not an option, precision is not a number on a print; it is a culture of uncompromising control over every variable in the process.