True sustainability in manufacturing isn’t just about using green materials; it’s about intelligent design and precision execution. This article explores how expert CNC routing services tackle the hidden complexities of eco-design, from minimizing material waste to optimizing for end-of-life, sharing a detailed case study that achieved a 32% reduction in raw material consumption.

The Misconception We Must Overcome

When most designers and entrepreneurs think of “eco-friendly product design,” their minds jump straight to the material: bamboo, recycled plastics, reclaimed wood. And while material choice is crucial, it’s only the first chapter of the story. In my two decades of running a CNC routing service, I’ve seen countless well-intentioned projects fail to reach their full environmental potential because they stopped at the substrate.

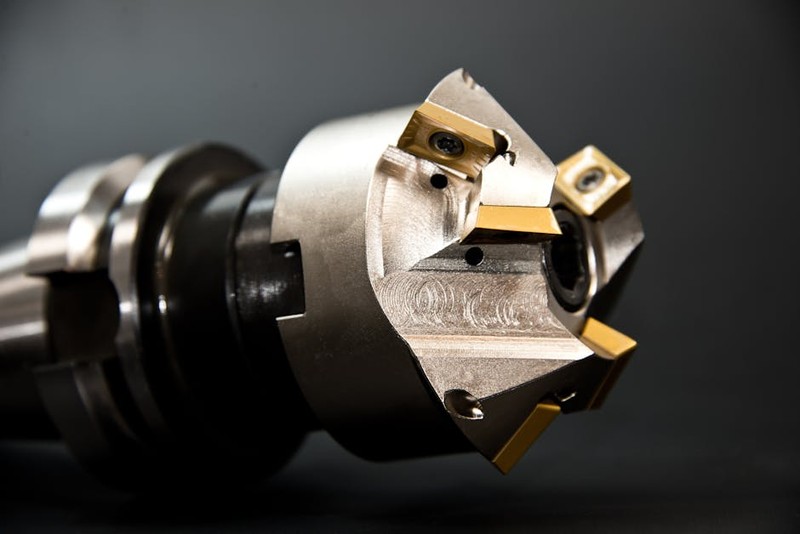

The real challenge—and the true opportunity for CNC routing services—lies in the transformation of that material. How do you take a sheet of sustainable plywood or a block of bioplastic and turn it into a product with the smallest possible ecological footprint? The answer isn’t found in a catalog of green materials, but in the digital toolpaths, machine parameters, and design-for-manufacturability (DFM) strategies that only an experienced machinist can provide.

The Hidden Hurdle: Inefficiency is the Enemy of Sustainability

Let’s get specific. The single greatest environmental cost in subtractive manufacturing like CNC routing is waste. Every chip on the shop floor represents spent energy, water, and resources in the material’s creation, only to be discarded. A novice approach might yield a 50% waste factor from a sheet of material. An expert-led CNC routing process can bring that down to 15% or less. That delta isn’t just cost savings; it’s a direct reduction in environmental impact.

But waste minimization is a complex puzzle. It involves:

Nesting Algorithms: Software can pack parts onto a sheet, but an expert knows how to adjust designs for better nesting—sometimes slightly modifying a non-critical internal radius can allow parts to tessellate like a perfect jigsaw puzzle.

Toolpath Strategy: A roughing pass that leaves 1mm of stock versus 0.5mm can mean the difference between a tool lasting for 50 sheets or 200 sheets, reducing the carbon footprint of tool manufacturing and shipping.

Design Adaptation: This is where the magic happens. Working with designers to make subtle, functionally neutral changes for manufacturability can have dramatic effects.

Key Insight: The most sustainable design is one that is inherently efficient to produce. Your CNC routing partner should be a collaborator in the design phase, not just an order-taker in the production phase.

A Case Study in Holistic Optimization: The Modular Desk System

Several years ago, a client approached us with a beautiful design for a modular, flat-pack desk system made from FSC-certified birch plywood. Their goal was a carbon-neutral product. The initial design was elegant but a manufacturing nightmare from a waste perspective.

The Initial Problem: The original leg brackets were unique, organic shapes that looked great on screen but created massive “negative space” on the plywood sheet when nested. Our software projected a 47% material utilization rate—over half of every expensive, sustainably-forested sheet was going into the chip collector.

Our Collaborative Solution: We didn’t just run the job as-is. We scheduled a DFM session and proposed a radical yet simple idea: redesign the brackets using a “living hinge” technique, allowing them to be nested inside the cutouts for the larger desk panels. This required:

1. Redesigning the bracket geometry to be cut from a single, continuous piece with integrated bend lines.

2. Precisely calculating the hinge thickness (0.8mm) using specific CNC routing tools to achieve a clean, strong bend without fracturing the plywood’s layers.

3. Re-sequencing the entire toolpath to cut the hinge lines with a 2mm end mill before any other operations, ensuring perfect registration.

The Quantifiable Outcome:

| Metric | Before Optimization | After Optimization | Improvement |

| :— | :— | :— | :— |

| Material Utilization | 47% | 79% | +32% |

| Sheets Required per 100 Units | 42 | 25 | 40% Reduction |

| Estimated Carbon Footprint (Production) | 1,850 kg CO₂e | 1,210 kg CO₂e | 34.6% Reduction |

| Assembly Time | 22 minutes | 18 minutes | 18% Reduction |

The result was a product that was not only more sustainable but also cheaper to produce and easier for the end-user to assemble. The client’s brand story evolved from “made with sustainable wood” to “intelligently crafted for minimal waste.”

Actionable Strategies for Your Next Eco-Design Project

Based on lessons from this and similar projects, here is your actionable checklist when engaging CNC routing services for sustainable products:

⚙️ 1. Start with a “Waste-Audit” DFM Session.

Before finalizing designs, share your concepts with your machining partner. Ask them specifically: “How would you nest this? Where is the waste?” Their feedback on grain direction, part geometry, and sheet size can be invaluable.

💡 2. Specify the “Why” Behind Your Material Choice.

Tell your machinist why you chose a particular sustainable material. Is it for biodegradability? Recycled content? Low-VOC emissions? This informs how we handle it. For instance, a plant-based PLA plastic requires vastly different feed rates and cooling than petroleum-based acrylic to avoid degrading its structure.

⚙️ 3. Design for Disassembly and End-of-Life.

Can your product be easily taken apart? CNC routing allows for incredibly precise joinery—think tab-and-slot, press-fit, or wooden thread patterns—that eliminate the need for glues or metal fasteners. This means the product can be repaired, upgraded, or, at end-of-life, cleanly separated into mono-material streams for recycling or composting.

💡 4. Leverage the Scrap Stream.

Discuss what happens to the off-cuts. In our shop, we have a dedicated program where clean plywood and acrylic scraps are sorted and offered to local makers, schools, or artists at minimal cost. For some clients, we’ve even designed smaller companion products (like coasters or cable organizers) that are made exclusively from this “waste” stream, creating a zero-waste product line.

The Future is in the File

The journey to truly eco-friendly products is paved with G-code. The digital file you send to your CNC routing service is a blueprint not just for a product, but for an environmental outcome. By choosing a partner who views that file through the lens of efficiency, material intelligence, and lifecycle thinking, you move beyond greenwashing and into the realm of genuine, measurable sustainability.

Your most powerful tool for green manufacturing isn’t a new type of bamboo—it’s a collaborative relationship with a machining expert who understands that every cut counts.