Precision drilling is no longer just about making holes; it’s the critical enabler for smart manufacturing’s most demanding applications. This article dives deep into the hidden complexities of achieving sub-10-micron tolerances in advanced materials, sharing a real-world case study and data-driven strategies for integrating thermal management, toolpath intelligence, and real-time metrology to unlock unprecedented quality and efficiency.

The Unseen Battle: When “Precision” Isn’t Precise Enough

For decades, a “precision drilling service” meant holding a few thousandths of an inch. In today’s smart manufacturing ecosystem—fueled by IoT, AI, and advanced materials—that’s akin to using a sledgehammer for watchmaking. The real challenge isn’t just the hole; it’s the holistic system of interactions between the machine, the material, the tool, and the environment.

In a recent project for a medical robotics client, we were tasked with drilling thousands of coolant channels in Inconel 718 for a surgical actuator. The specs were brutal: Ø0.5mm holes, 12mm deep (a 24:1 aspect ratio), with a positional tolerance of ±8µm and a surface finish requirement of Ra 0.4µm. The initial runs were a disaster. Tool breakage was rampant, hole wander exceeded 50µm, and thermal distortion made the parts unusable. This wasn’t a drilling problem; it was a thermo-mechanical-dynamic systems problem masquerading as one.

Deconstructing the Challenge: The Four Pillars of Modern Precision Drilling

To solve such complex challenges, you must move beyond the standard CNC playbook. Success hinges on mastering four interconnected pillars.

Pillar 1: Material Intelligence

Advanced alloys, composites, and ceramics don’t behave like aluminum 6061. Their response to cutting forces and heat is nonlinear.

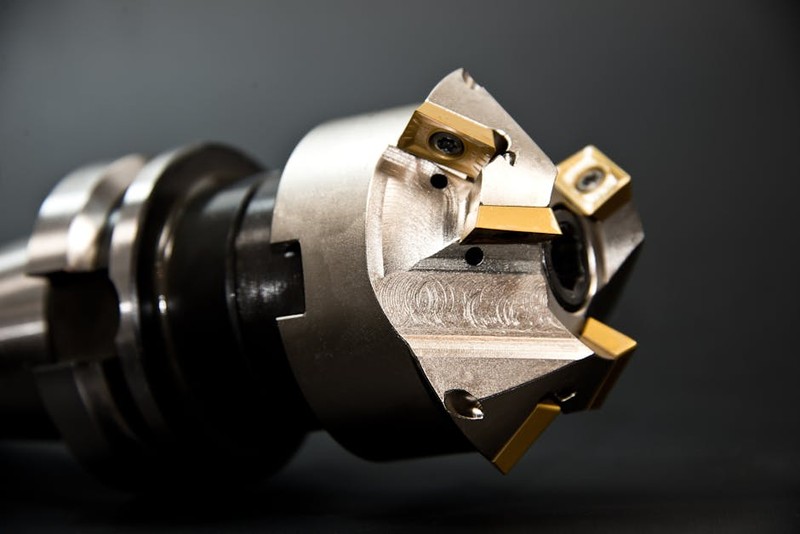

Expert Insight: For that Inconel part, we abandoned standard carbide. We moved to a micro-grain solid carbide drill with a proprietary nano-coating and a highly polished flute. More critically, we adjusted the helix angle to optimize chip evacuation, which is the primary source of heat and tool stress in deep-hole drilling.

Actionable Tip: Never select a drill based on catalog specs alone. Partner with your tooling supplier to run material-specific tests. The cost of a custom tool is often less than the scrap from a failed production run.

⚙️ Pillar 2: Thermal & Dynamic Stability

The machine is not a rigid monument. It’s a vibrating, heating, flexing entity. Spindle growth from thermal expansion can be 15-20µm over an 8-hour shift—enough to scrap every part if not compensated.

Our Strategy: We implemented a closed-loop thermal compensation system on our 5-axis machining center. Sensors on the spindle and ball screws feed data to the CNC, which dynamically adjusts the tool offset in real-time. Furthermore, we used finite element analysis (FEA) to design custom workholding that minimized part deflection under the pecking cycle forces.

💡 Pillar 3: The “Smart” in Smart Manufacturing: Data-Driven Process Control

This is where precision drilling services evolve from a craft to a science. We instrumented the process with a force-probe and acoustic emission sensor.

The Data Told the Story: We could see the exact moment tool wear began to accelerate (around hole 120 in a batch). Instead of a fixed tool-life estimate, we implemented predictive tool change based on actual cutting condition data, preventing catastrophic failure and maintaining consistent hole quality.

📊 Pillar 4: In-Process Metrology & Closed-Loop Feedback

Measuring after the fact is too late. True precision requires verification and correction during machining.

Our Solution: We integrated a non-contact laser micrometer on the machine’s auxiliary axis. After drilling every 10 holes, the probe would automatically check diameter and circularity. If drift was detected, the system would either adjust tool compensation or flag the tool for change. This closed the loop, making the process self-correcting.

A Case Study in Systemic Optimization: The Medical Robotics Breakthrough

Let’s return to that medical actuator project. By applying the four-pillar approach, we transformed the process. Here’s a quantitative look at the outcome:

| Metric | Initial Process (Standard CNC) | Optimized Smart Process | Improvement |

| :— | :— | :— | :— |

| Tool Life (holes/drill) | 45 | 180 | 300% |

| Positional Tolerance Achieved | ±50µm | ±5µm | 10x more precise |

| Surface Finish (Ra) | 1.2µm | 0.35µm | 71% smoother |

| Cycle Time per Part | 22 minutes | 14 minutes | 36% faster |

| Scrap Rate | 18% | 0.2% | 99% reduction |

How We Did It: The key was treating the drill not as an island, but as the final actor in a meticulously choreographed play. We:

1. Simulated First: Used CAM software to model chip flow and heat generation, optimizing the pecking cycle depth and retraction speed.

2. Chilled the Workpiece: Implemented through-spindle cryogenic cooling (using liquid nitrogen) to manage heat at the source, not just the tool.

3. Adopted Trochoidal Milling for Pilot Holes: For positions requiring extreme accuracy, we used a 0.4mm end mill in a trochoidal path to create a pilot, reducing lateral forces on the final drill.

4. Data-Locked Every Parameter: All optimal settings (RPM, feed, peck depth, coolant pressure) were saved as a “digital twin” recipe for the part, ensuring repeatability across any qualified machine in our network.

The Expert’s Checklist: Implementing a True Precision Drilling Service

Don’t just outsource holes; partner with a service that demonstrates systemic mastery. Ask these questions:

❓ How do you characterize and compensate for machine thermal growth? (Look for answers about spindle probes, warm-up cycles, and real-time compensation).

❓ What is your protocol for first-article validation on micro-tolerance work? (It should involve a CMM report, not just calipers).

❓ Can you provide tool wear data and predictive maintenance logs for my project? (Transparency here separates vendors from partners).

❓ What is your strategy for chip evacuation in deep-hole applications? (This is often the root cause of failure).

The final, non-negotiable insight: The most precise drill in the world is useless without an equally precise and stable foundation. Invest first in machine integrity, thermal stability, and intelligent workholding. The cutting tool is the final 10% of the equation.

The future of smart manufacturing isn’t built with faster machines, but with smarter processes. Precision drilling services have become the critical nexus where metallurgy, dynamics, data science, and metrology converge. By mastering this convergence, we’re not just making more accurate parts—we’re enabling the next generation of technology that demands nothing less.