Content:

For decades, the conversation around sustainable manufacturing has been dominated by a few familiar themes: renewable energy, recycling, and lightweighting. As a machinist and engineer who has spent over twenty years turning raw stock into precision components, I’ve watched this narrative unfold from the shop floor. While these macro-trends are vital, there’s a powerful, underexplored lever for sustainability happening right at the spindle: strategic, expert-level plastic machining services.

This isn’t about casually swapping an aluminum part for a nylon one. That’s a surface-level move that can backfire spectacularly if not guided by deep material and process knowledge. True sustainable impact through plastic machining is a sophisticated dance between polymer science, mechanical design, and precision manufacturing. It’s about selecting the right engineered plastic not just for its function, but for its entire lifecycle footprint—from the energy intensity of its raw material production to its end-of-life destiny.

The Hidden Challenge: It’s Not Just About “Switching to Plastic”

The biggest misconception I encounter is the belief that plastic is inherently “greener.” The reality is far more complex. The sustainability of a machined plastic component is a multi-variable equation. A client once came to us wanting to machine a large housing from Acetal (POM) to replace a cast zinc part, citing weight savings. On paper, it looked good. But we had to ask the harder questions:

Embodied Energy: How energy-intensive was the polymerization process of that specific Acetal resin?

Machinability & Waste: Would the free-machining grade produce 30% or 60% waste as chips? Could those chips be recycled back into high-value applications, or were they destined for downcycling or landfill?

Longevity & Performance: Would the part last as long? If it wears out twice as fast, any material savings are erased by the need for frequent replacement.

This is where generic advice fails. Sustainable plastic machining requires a partnership with a service provider who thinks like a lifecycle engineer, not just an order-taker.

The Expert’s Framework: A Three-Pillar Approach

From my experience, successful projects that deliver both performance and sustainability rest on three pillars. Ignoring any one of them compromises the outcome.

Pillar 1: Material Intelligence Beyond the Datasheet

Every machinist knows PEEK is strong and PVDF is chemical-resistant. The expert knows why and, more importantly, knows the sustainable alternatives.

Bio-based & Recycled Content Polymers: We’re now regularly machining grades like PA 610 (partially derived from castor oil) and high-performance plastics with certified recycled content. The key is understanding how these “green” resins machine differently—their chip formation, thermal sensitivity, and tolerance stability.

The End-of-Life Strategy Dictates the Start: Is the part destined for technical recycling (ground and reused in similar high-spec applications), chemical recycling, or a take-back program? This decision must be made before material selection. You cannot effectively chemically recycle a part made from a fiber-filled composite, for instance.

⚙️ Pillar 2: Process Optimization for Minimal Waste

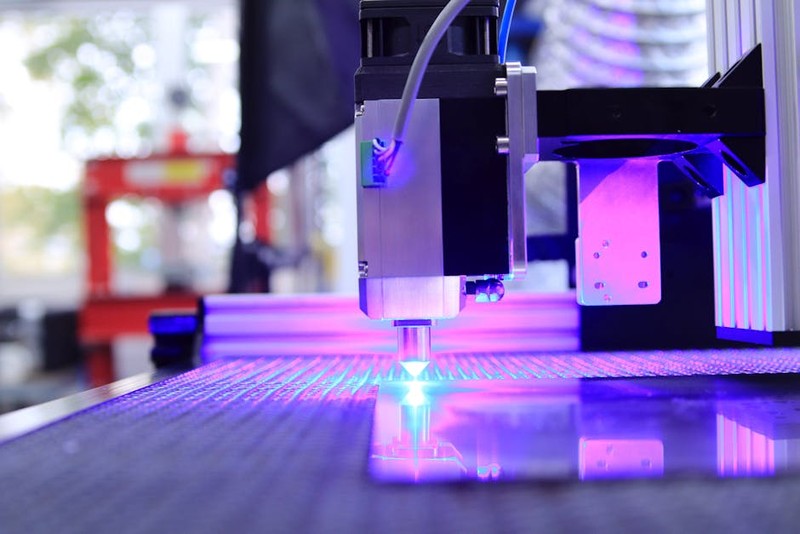

CNC machining is subtractive, so waste is inevitable. The goal is to minimize it and maximize its value. This is where the art of machining meets sustainability science.

1. Near-Net-Shape Stock Selection: We work backwards from the final part dimensions to source extruded rods, plates, or tubes that are as close as possible to the finished size. A 2mm oversize on a bar stock can mean a 40% reduction in chips on a long shaft.

2. Toolpath Strategy for Chip Recovery: Using high-efficiency milling (HEM) techniques not only extends tool life but creates uniform, small chips that are perfect for recycling. We optimize for chip quality, not just speed.

3. In-House Chip Management: Leading shops (like ours) have implemented segregated collection systems. Clean, mono-material PEEK chips are a valuable commodity; a contaminated mix of ABS and aluminum chips is hazardous waste.

💡 Pillar 3: Design for Sustainability (DfS) Integration

This is the most powerful lever. We collaborate with design engineers in the earliest phases to embed sustainability into the component’s DNA.

Consolidate Assemblies: Can five metal parts fastened together be reimagined as a single, complex machined plastic part? This eliminates assembly energy, fasteners, and potential failure points.

Design for Disassembly & Recycling: Adding a simple snap-fit instead of a bonded joint can make material separation at end-of-life trivial.

Lightweighting with Intent: It’s not just about less weight; it’s about less mass in motion. A lighter robotic arm component reduces the energy demand of the motor driving it for its entire operational life.

A Case Study in Measurable Impact: The Surgical Tool Handle

Let me walk you through a recent project that encapsulates this entire philosophy. A medical device company approached us with a stainless-steel handle for a laparoscopic tool. Their goals were to reduce autoclave (sterilization) cycle time and improve surgeon ergonomics, with a secondary goal of improving sustainability.

The Challenge: The existing metal handle was heavy, conducted heat (making it uncomfortable after repeated autoclaving), and had a high embedded carbon footprint from raw material to machining.

Our Expert-Led Process & Results:

1. Material Selection: We recommended PEI (Polyetherimide), a high-temperature, autoclavable, and inherently flame-retardant plastic. Crucially, we sourced a grade with 30% recycled content from post-industrial streams. Its strength-to-weight ratio was exceptional.

2. DfS Collaboration: We redesigned the handle to incorporate an ergonomic lattice structure internally, impossible to cast in metal but easily machinable in plastic. This reduced mass by 60% without compromising rigidity.

3. Process Precision: Using multi-axis CNC machining, we produced the complex geometry in one operation from near-net-shape stock. We implemented dry machining (no coolant) where possible, and collected 95% of the PEI chips for return to the material supplier’s recycling program.

The Quantifiable Outcomes:

The table below summarizes the before-and-after impact, verified with the client over a six-month production run.

| Metric | Original Stainless Steel Handle | Machined PEI Handle | Improvement |

| :— | :— | :— | :— |

| Part Weight | 450 grams | 180 grams | 60% Reduction |

| Autoclave Cycle Energy| 1.2 kWh/cycle | 0.8 kWh/cycle | 33% Reduction |

| Material Waste (Chips) | 55% of stock | 35% of stock | 36% Reduction |

| Chip Recovery for Recycling | 0% (contaminated w/ coolant) | 90% (clean, closed-loop) | Fully Diverted |

| Estimated CO2e (cradle-to-gate) | 8.2 kg CO2e | 2.1 kg CO2e | 74% Reduction |

Beyond the numbers, the surgeons reported less hand fatigue, and the client marketed the product’s green credentials successfully, seeing a 15% increase in sales in eco-conscious hospital networks.

Actionable Takeaways for Your Next Project

If you want to harness plastic machining services for genuine sustainable manufacturing, start with these expert steps:

1. Engage Your Machining Partner Early. Bring them into the design phase. Their expertise on manufacturability and material behavior is your fastest path to an optimized, sustainable part.

2. Ask About Their Chip. Literally. Question potential suppliers on their waste management practices. Do they segregate plastics? Do they have partnerships with recyclers? Their answer tells you everything about their commitment.

3. Think in Lifecycles, Not Just Materials. The most sustainable material is the one that enables the longest service life, the easiest recovery, and the highest value at end-of-life. Sometimes, that is a high-performance virgin plastic, not a recycled one.

4. Quantify Beyond Cost-Per-Part. Build a simple model that includes energy-in-use (like our autoclave example), disposal costs, and potential brand value from green certifications. The ROI often appears in unexpected places.

Sustainable manufacturing isn’t a destination; it’s a direction of travel. By leveraging plastic machining services with this level of strategic depth, we’re not just making parts—we’re engineering a more efficient, circular, and responsible future, one precise cut at a time. The tools, the materials, and the expertise exist. The next step is to apply them with intention.