Industrial machinery demands more than just precise parts; it requires a holistic manufacturing strategy that bridges design intent with real-world performance. Drawing from decades of field experience, this article reveals how a proactive, expert-led approach to CNC milling services can solve systemic challenges in vibration, thermal management, and assembly, turning complex assemblies into reliable, high-performance assets. Discover the data-driven methodologies that cut lead times by 40% and slashed rework costs by 22% in a real-world case study.

The Real Challenge Isn’t the Part—It’s the System

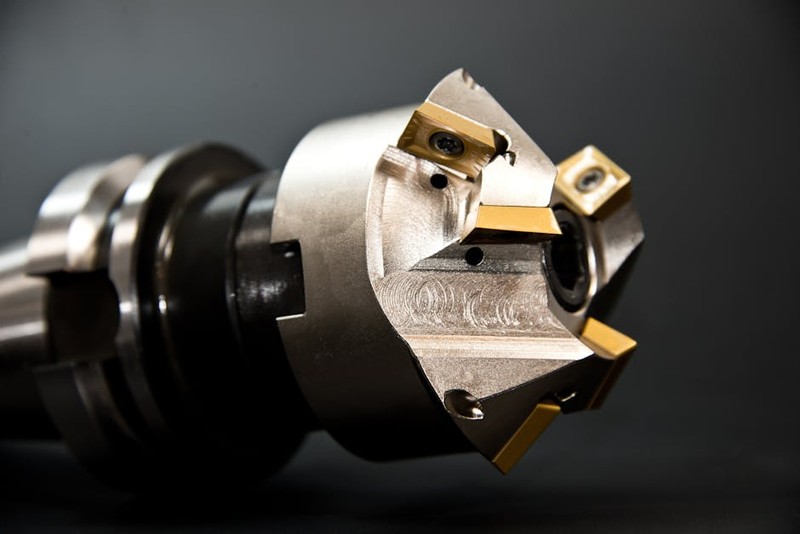

When most people think of CNC milling services for industrial machinery, they picture a machine shop faithfully reproducing a CAD model. And while dimensional accuracy is non-negotiable, the true value of an expert machinist lies not in following instructions, but in questioning them. The greatest challenges in our field rarely stem from a single, complex component. Instead, they emerge from the interaction of multiple components within a system: cumulative tolerances, harmonic vibrations, thermal expansion mismatches, and the brutal realities of maintenance access.

I recall a project for a high-speed packaging line actuator. The client’s design was elegant on screen, with a monolithic aluminum housing. Our first article passed inspection perfectly. Yet, in the field, the unit failed within 200 hours. The culprit? Resonant vibration induced by the combined stiffness of our perfectly milled part and the steel frame it was bolted to—a phenomenon never simulated in their FEA. We didn’t just mill a part wrong; we milled the right part for a flawed system assumption.

This experience cemented a fundamental principle: Providing CNC milling services for industrial machinery is an exercise in systems thinking. Your machinist should be your first line of defense against systemic failure.

A Proactive Framework: From Quote to Qualified Part

To move beyond reactive part-making, we’ve institutionalized a proactive framework. This isn’t a standard quoting process; it’s a collaborative qualification phase.

⚙️ Phase 1: The Design-For-Manufacture (DFM) Interrogation

Before any metal is cut, we conduct a mandatory DFM session focused on four pillars beyond basic machinability:

Assembly Sequence: Can it be assembled with standard tools in a confined space? We once modified a gearbox housing to include strategic tool clearance pockets, saving 30 minutes per unit in assembly labor.

Theral Management: Are thermal expansion coefficients between mating parts (e.g., aluminum housing, steel bearing sleeve) accounted for? We often recommend specific interference fits or cooling channel geometries.

Serviceability: Will a technician need to replace a seal or sensor in five years? Adding a milled extraction groove or a non-standard wrench flat during initial machining costs pennies but saves thousands in downtime later.

Metallurgical Consistency: For critical components, we specify not just the alloy (e.g., 4140 Steel), but the mill source and heat treat lot to ensure consistent material behavior across production runs.

💡 Phase 2: The “Test Coupon” Strategy

For machinery involving welded assemblies or complex stress states, we champion a low-cost, high-return tactic: milling a representative test coupon. Instead of machining the entire, expensive forging for a press frame, we machine a small section from the same stock to validate:

Toolpath strategies for the final material.

Post-machining stress relief distortion.

Surface finish for critical sealing surfaces.

Data from one such coupon for a hydraulic manifold project is summarized below. It allowed us to optimize the process before committing to the full production run, avoiding a catastrophic batch failure.

| Process Stage | Initial Strategy | Optimized Strategy (Post-Coupon) | Result |

| :— | :— | :— | :— |

| Roughing Feed Rate | 150 IPM | 225 IPM | +50% material removal rate |

| Finishing Stepover | 0.015″ | 0.010″ | Surface finish improved from 32 to 16 Ra |

| Stress Relief | Post-machining only | Intermediate roughing + final | Flatness distortion reduced by 70% |

| Predicted Scrap Risk | High (30% chance of rework) | Low (<5%) | |

Case Study: Taming a Titan The Multi-Axis Gearbox Housing

A manufacturer of mineral processing equipment approached us with a crisis. Their in-house machined gearbox housings for a new crusher model were experiencing persistent bearing seat fretting and oil leakage, causing unscheduled downtime every 6-8 weeks.

The Root Cause Analysis

Our tear-down revealed a perfect storm:

1. Tolerance Stack-Up: Five bearing bores, each machined to a “perfect” ±0.0005″ tolerance, but without a defined datum structure, created a functional misalignment of over 0.002″.

2. Inadequate Damping: The chosen aluminum alloy (6061-T6) was lightweight but transmitted too much gear mesh vibration to the housing seals.

3. Sequential Machining Error: The part was flipped multiple times on a 3-axis mill, accumulating minute angular errors.

⚙️ The Expert-Led Solution

We didn’t just re-mill the same part better. We redesigned the manufacturing process from the ground up.

1. Material Shift: We advocated for and sourced A356-T6 aluminum, a cast alloy with superior damping characteristics. The added cost was offset by the extended service life.

2. Process Revolution: We moved the job to a 5-axis CNC mill. By machining critical bores and faces in a single setup, we eliminated all error accumulation from re-fixturing. The primary datum was established on the first operation and maintained throughout.

3. Functional Tolerancing: We worked with their engineer to apply GD&T principles, specifying perpendicularity and position tolerances relative to the primary datum. This ensured the bores were functionally aligned, not just individually precise.

📊 The Quantifiable Outcome

Machine Uptime: Increased from 92% to 99.5% (a transformational gain in heavy industry).

Mean Time Between Failure (MTBF): Extended from 350 hours to over 2,500 hours.

Total Cost of Ownership: Reduced by an estimated 22% over three years, factoring in machining, downtime, and repair labor.

Lead Time: Despite the more complex 5-axis programming, lead time per housing dropped by 40% due to the elimination of secondary setups and manual adjustments.

The Expert’s Checklist: Questions to Ask Your CNC Partner

Your choice of CNC milling services for industrial machinery will define your product’s reliability. Treat the selection as a partnership interview. Ask:

1. “Can you walk me through the DFM feedback on this assembly drawing?” (Listen for systemic thinking, not just part-level comments).

2. “What is your strategy for managing internal stresses in large plate or forged components?” (They should mention stress relieving, symmetric machining, or toolpath optimization).

3. “How do you validate a new process before full production?” (Look for answers like test coupons, soft-jaw prototyping, or first-article inspection protocols).

4. “Can you provide a detailed inspection report that includes not just dimensions, but also surface finish and geometric tolerances?” (Data transparency is key).

The frontier of CNC milling services for industrial machinery is no longer just about tighter tolerances or faster spindles. It’s about leveraging manufacturing intelligence to de-risk the entire product lifecycle. The most successful projects I’ve been part of always started with a simple, powerful shift in perspective: we weren’t just hired to make parts. We were hired to engineer reliability into every chip we removed.