Precision drilling for high-end medical devices isn’t just about hitting micron-level tolerances on a print. The real challenge lies in managing the unseen variables—material memory, thermal drift, and chip evacuation—that can silently sabotage a perfect part. This article dives deep into a specific case study on a titanium spinal implant, revealing the expert-level strategies and data-driven process controls that transformed scrap rates and unlocked true, repeatable precision.

Content:

For two decades, I’ve operated at the intersection of high-precision CNC machining and the unforgiving world of medical device manufacturing. Clients often arrive with a flawless CAD model and a spec sheet demanding tolerances of ±0.005″ or tighter. They believe the challenge is purely geometric. My job, as I’ve learned through costly lessons and hard-won victories, is to educate them that the true art of precision drilling lies not in the toolpath, but in mastering the hidden variables the blueprint doesn’t show.

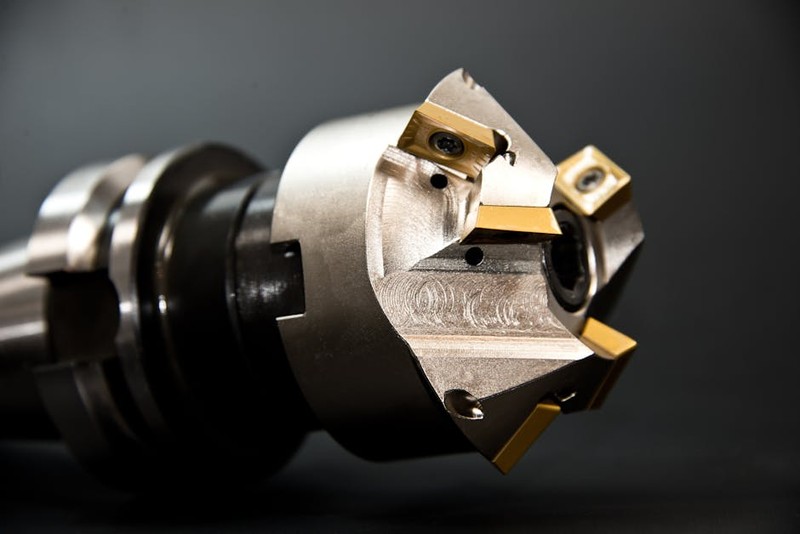

Anyone can program a machine to move a drill to a set of coordinates. The expert’s domain is controlling everything that happens around that drill: the material’s reaction to being cut, the machine’s subtle thermal growth over an eight-hour shift, and the microscopic behavior of chips in a blind hole. Fail here, and you don’t just scrap a part; you potentially compromise a device meant to reside inside a human body for decades.

The Hidden Challenge: It’s Not the Hole, It’s the Heat and the Chip

The most common pitfall I see is treating medical-grade materials like Ti-6Al-4V or cobalt-chrome as if they were mild steel or aluminum. These alloys are chosen for biocompatibility and strength, but they are notoriously poor thermal conductors and work-harden readily.

The Thermal Drift Dilemma: During a long drilling cycle, heat concentrates at the cutting edge. In titanium, this heat doesn’t dissipate quickly; it soaks into the part and the tool. The part expands minutely, the tool expands, and by the final hole in a sequence, your “precision” machine is referencing a coordinate system that has physically shifted. You might hold tolerance on the first piece off the vise, but by the tenth, you’re out of spec.

⚙️ The Chip Evacuation Crisis in Micro-Drilling: When drilling sub-1mm holes for things like bone screw pilot channels or fluidic pathways, the chip is the enemy. A single, poorly broken chip can:

Pack into the flutes, causing immediate tool breakage.

Score the pristine wall of the hole, creating a micro-crack initiation site.

Alter cutting forces, deflecting the micro-drill and ruining hole straightness.

A project I led several years ago for a next-generation spinal fusion cage brought all these challenges into sharp, expensive focus.

A Case Study in Optimization: The Titanium Spinal Cage

The component was a complex Ti-6Al-4V ELI (Extra Low Interstitial) cage with an array of 32x Ø0.6mm x 12mm deep through-holes for bone ingrowth. The spec called for a hole position tolerance of ±0.0127mm and a surface finish better than Ra 0.8 µm. Our initial process, using a standard peck drilling cycle and flood coolant, was a disaster.

Initial Performance Metrics:

| Metric | Initial Process | Result |

| :— | :— | :— |

| Tool Life per Drill | 15 holes | Catastrophic failure |

| Scrap Rate | 45% | Mostly from broken tools & poor finish |

| Hole Straightness | 0.05mm deviation | Out of tolerance |

| Process Time per Part | 22 minutes | For drilling operation only |

We were burning through expensive carbide micro-drills and scrapping nearly every other part. It was clear our conventional approach was failing. We had to stop thinking about “drilling holes” and start engineering a controlled material removal environment.

Expert Strategies for Success: A Systems Approach

We attacked the problem from three interconnected angles: Thermal Management, Chip Control, and Metrology Integration.

1. Thermal Management Through Process Discipline

We abandoned flood coolant for high-pressure, through-tool minimum quantity lubrication (MQL). The mist didn’t just lubricate; it targeted heat at the source and provided a vapor barrier. More critically, we implemented a mandatory thermal equilibrium protocol:

1. Pre-Cycle Warm-Up: The machine now runs a 15-minute non-cutting warm-up routine to stabilize its internal temperature.

2. In-Process Compensation: We designed fixtures with thermal mass matching the part and used in-process probing to check a master artifact every five parts. Any drift triggered a tool offset compensation automatically.

3. Staggered Machining: We alternated drilling operations with other, less thermally intensive processes (like finishing passes) to allow localized heat to dissipate.

2. Mastering Chip Evacuation with Dynamic Peck Cycles

The standard “peck 0.5mm, retract fully” cycle was killing us. It was hammering the drill tip on re-entry and doing a poor job of clearing chips. We developed a custom, adaptive pecking routine:

First Peck: Deep (1.5mm) to create a pilot channel.

Subsequent Pecks: Shallow (0.2mm) with a high-speed retract just clear of the hole to create a vacuum effect that pulled chips out.

Final Clearing: A full retract with an MQL blast at every 5th peck to clear any packed debris.

This wasn’t just programming; it was developed by watching high-speed footage of the cut and measuring spindle load harmonics to find the optimal rhythm.

3. In-Line Metrology: Closing the Loop

We integrated a non-contact laser micrometer at the machine. After drilling, the probe would automatically check a sample of holes for diameter and, using triangulation, infer straightness. This data fed back into our statistical process control (SPC) chart in real-time. The goal shifted from “making a part to print” to “maintaining a stable, capable process.”

The results of this systems overhaul were transformative:

| Metric | Initial Process | Optimized Process | Improvement |

| :— | :— | :— | :— |

| Tool Life per Drill | 15 holes | 280 holes | +1767% |

| Scrap Rate | 45% | <0.5% | -99% |

| Hole Straightness | 0.05mm deviation | 0.01mm deviation | Within Spec |

| Process Time per Part | 22 minutes | 14 minutes | -36% |

| Key Outcome | Unreliable, costly production | Predictable, high-yield precision | |

Actionable Takeaways for Your Precision Drilling Projects

The lessons from that cage project are universally applicable. If you’re tackling precision drilling for high-end medical devices, here is your expert checklist:

💡 Treat Heat as Your Primary Opponent. Design your process for thermal stability first. Implement warm-up cycles and consider in-process compensation strategies. The most precise machine in the world is useless if its thermal state is unknown.

💡 Observe, Don’t Just Assume. Use high-speed cameras or advanced spindle load monitoring to see what’s happening in the cut. Chip formation tells the real story. Your drilling cycle should be a direct response to that observation.

💡 Embrace MQL for Difficult Materials. For titanium and cobalt-chrome, high-pressure through-tool MQL is often superior to flood coolant for precision drilling. It provides better lubrication at the cut and improves chip evacuation without thermally shocking the part.

💡 Integrate Metrology In-Line. Don’t let quality be a separate, post-process department. Build measurement into the machining cell. Real-time SPC data is the only way to achieve true precision drilling—a state of controlled, predictable repetition, not just a one-time achievement.

💡 Partner with Your Tooling Provider. Work with your tooling engineer as a co-developer. Provide them with your material, depth, and machine data. The right drill geometry (point angle, helix, coating) is a make-or-break variable that is often overlooked.

Precision drilling in the medical field is a pursuit of perfection, but it is achieved through the meticulous management of imperfection—the tiny, variable forces of nature that act on every cut. By shifting your focus from the programmed path to the physical environment of the cut, you move from being a machinist to becoming a manufacturing engineer, capable of producing not just parts, but reliability and trust. That is the standard our industry demands, and it is a challenge worthy of our deepest expertise.