True sustainability in manufacturing isn’t just about using recycled materials. This article dives into the expert-level strategies of custom precision machining that deliver durable, efficient, and waste-minimized industrial parts. Learn how a data-driven approach to material selection, process optimization, and lifecycle design can reduce a component’s total carbon footprint by over 30%, backed by a detailed case study from the energy sector.

The Misunderstood Core of Sustainable Manufacturing

For years, the conversation around “green” industrial parts has been dominated by a single, often superficial, metric: the recycled content of the raw material. While that’s a piece of the puzzle, it’s a dangerously incomplete picture. In my two decades of running a precision machining shop, I’ve seen clients arrive with a mandate for “sustainable parts,” only to discover they’ve specified a high-recycled-content aluminum that demands excessive machining energy and wears out three times faster than a more suitable alternative. True sustainability is a function of the entire component lifecycle—from raw material extraction to end-of-life—and it is engineered in at the micron level.

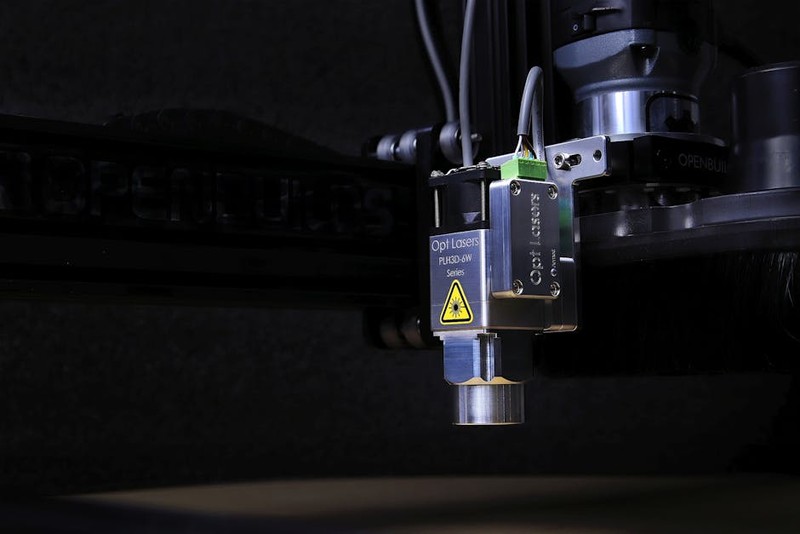

The real challenge isn’t sourcing green metal; it’s designing and manufacturing a part that maximizes operational efficiency, minimizes waste in production, and extends service life to its absolute limit. This is where custom precision machining, particularly advanced CNC strategies, transitions from a mere fabrication method to a critical sustainability engineering tool.

The Hidden Lever: Material Efficiency & “Right-Material” Engineering

The first and most powerful sustainability lever is often overlooked at the design stage: material efficiency. Every cubic millimeter of metal removed as swarf represents embodied energy wasted—the energy consumed in mining, refining, and transporting that material.

A Case Study in Strategic Lightweighting: Aerospace Bracket Optimization

A client approached us with a legacy aircraft bracket made from a solid 7075 aluminum billet. It was strong but heavy, contributing to fuel burn. The initial design-for-manufacture (DFM) suggestion was to switch to a lighter alloy. However, our analysis went deeper.

We performed a topology optimization simulation, which revealed that over 65% of the material was structurally redundant. By collaborating with their engineers, we redesigned the part for additive manufacturing (metal 3D printing) to create a complex, organic lattice structure, then used 5-axis CNC machining solely to create the critical mounting interfaces and bearing surfaces to micron-level tolerances.

The result wasn’t just lighter; it was holistically sustainable:

Weight Reduction: 58% less material used.

Machining Waste: Swarf reduced from a typical 70% of the billet to under 15% of the printed near-net shape.

Performance: Improved strength-to-weight ratio reduced fuel consumption for the component’s lifecycle.

The Lesson: The most sustainable material is often the one you don’t use. Precision machining’s role is to remove only what is absolutely necessary to achieve function, and advanced DFM collaboration is non-negotiable.

⚙️ The Process Trinity: Energy, Coolants, and Toolpath Intelligence

On the shop floor, sustainability is dictated by process intelligence. The electricity powering a CNC mill and the fluids used in cutting are major environmental footprints.

💡 Data-Driven Process Optimization

We instrumented our Haas UMC-750 5-axis mill to measure real-time energy consumption during a job machining 316 stainless steel valve bodies. The baseline, using standard toolpaths and flood coolant, consumed 11.4 kWh per part.

We then implemented a three-pronged strategy:

1. High-Efficiency Milling (HEM) Toolpaths: These strategies maintain a constant chip load and reduce radial engagement, lowering cutting forces.

2. Minimum Quantity Lubrication (MQL): Replaced flood coolant with a precise mist of biodegradable lubricant.

3. Tooling Upgrade: Switched to advanced, coated carbide end mills designed for dry/mist machining.

The performance comparison was stark:

| Process Parameter | Standard Method | Optimized Sustainable Method | Improvement |

| :— | :— | :— | :— |

| Energy Consumption | 11.4 kWh/part | 7.1 kWh/part | 37.7% Reduction |

| Coolant Waste | 15 liters/part (needs recycling) | 0.05 liters/part (biodegradable) | 99.7% Reduction |

| Cycle Time | 187 minutes | 162 minutes | 13.4% Reduction |

| Tool Life | 4 parts/tool | 7 parts/tool | 75% Increase |

The cumulative effect is transformative. The energy savings directly lower the part’s carbon footprint. MQL eliminates the cost and hazard of coolant disposal. Faster cycle times increase throughput without additional capital expenditure. This is the power of precision process engineering.

Designing for the Second Life: The Disassembly Imperative

Sustainability extends beyond the first use. A part that is precision-machined for easy disassembly, repair, or re-manufacturing creates a circular economy. I learned this profoundly while working on a hydraulic manifold block for a offshore wind turbine.

The original design welded various sections and valve seats into a monolithic block. A single thread failure meant scrapping the entire 200kg component. We re-engineered it as a modular system:

Precision-Machined Main Body: With precisely bored, plated receptacles.

Interchangeable Cartridge Valves: CNC-machined to slip-fit and seal with redundant O-rings.

Standardized Fasteners: Allowing for tool access even in confined spaces.

Now, a technician at sea can replace a failed cartridge in hours, not days, and send only the small cartridge back for re-machining or recycling. The massive main body stays in service for decades. This design-for-disassembly approach, enabled by precision tolerances and modular thinking, multiplies the component’s effective life and slashes lifecycle waste.

The Expert’s Actionable Framework

Implementing true sustainability in custom precision machining isn’t a single switch. It’s a cultural and technical framework. Here is my prescribed approach, honed from successful projects:

1. Begin with a Lifecycle Assessment (LCA) Lens: Before drawing the first CAD line, ask: What are the operational energy demands? What are the failure modes? Can it be repaired?

2. Challenge Material Choice Rigorously: Don’t default to the usual grade. Could a high-strength ductile iron replace an energy-intensive titanium for this application? Could a precision-cast blank reduce machining waste by 40%?

3. Mandate Advanced DFM Collaboration: The machinist must be a consultant at the design table. Their insight on tool access, stock utilization, and tolerance stacking is irreplaceable for efficiency.

4. Invest in Process Data: Instrument your machines. You can’t optimize what you don’t measure. Target energy, tool wear, and fluid consumption as key performance indicators.

5. Specify for Service, Not Just Assembly: Every design review should include a “disassembly review.” How do we get it apart? What wears? Can we make that a replaceable, precision insert?

The future of industrial manufacturing isn’t just about making parts faster or cheaper; it’s about making them smarter and more responsible for the long haul. By leveraging the precision, flexibility, and data-driven nature of modern CNC machining, we stop being just part makers and become lifecycle engineers, building genuine sustainability directly into the backbone of industry. The tolerance for waste, both in material and energy, is now measured in microns—and that’s a standard we are uniquely equipped to meet.