Precision drilling for luxury components is not about making holes; it’s about engineering micro-scale perfection that defines the user experience. This article delves into the critical, often overlooked challenge of achieving flawless surface finishes in deep, small-diameter holes—a make-or-break factor for high-end products. We share a detailed case study and data-driven strategies to transform this hidden hurdle into a competitive advantage.

The Silent Saboteur: Why Surface Finish is the True Benchmark of Luxury

When most engineers think of precision drilling services, they focus on dimensional accuracy: hitting a ±0.005mm tolerance on a hole’s diameter or location. And while that’s crucial, it’s merely table stakes. In my two decades of machining components for high-end watches, medical devices, and aerospace-grade consumer tech, I’ve learned that the true differentiator—the element that separates a functional part from a luxury artifact—lies in a factor often relegated to a footnote on the drawing: the surface finish inside the hole.

Imagine a titanium hinge pin for a $20,000 eyewear frame. The pin fits perfectly, but if the bore it rotates within has microscopic tool marks, it will feel gritty, wear prematurely, and generate audible friction—a complete failure of the luxury promise of silent, buttery-smooth operation. This is the hidden challenge: achieving a mirror-like Ra (average roughness) value in deep, small-diameter holes where conventional tooling and coolant simply cannot reach.

A Case Study in Acoustic Perfection: The Chronograph Pusher

A few years back, a renowned Swiss watchmaker approached us with a persistent issue. Their chronograph pushers (the buttons on the side of a watch) had a slight, inconsistent “gritty” feel when depressed. The culprit? The 0.8mm diameter, 5mm deep guide hole in the 316L stainless steel case. The internal finish was specified as Ra 0.4µm, but batch inconsistencies led to tactile variance.

Our investigation revealed a multi-faceted problem:

Chip Evacuation: In such a small cavity, chips recut the wall, destroying finish.

Tool Deflection: A 0.8mm drill is like a noodle; any runout creates spiraling marks.

Coolant Access: Flood coolant couldn’t penetrate the depth, leading to heat buildup and built-up edge on the cutting tool.

The Expert’s Toolkit: A Multi-Pronged Strategy for Micro-Perfection

Solving this isn’t about one magic tool. It’s a symphony of controlled variables. Here’s the framework we developed and now apply to all luxury component precision drilling.

⚙️ Process 1: The “Peck-and-Pull” Protocol with a Twist

The standard peck drilling cycle (drill a bit, retract to clear chips) wasn’t enough. We engineered a “Peck, Pull, and Purge” cycle.

1. Peck: Advance 0.5 x diameter.

2. Full Retract: Pull the tool completely out of the hole.

3. High-Pressure Purge: A dedicated 80 PSI air blast clears the hole and tool flutes.

4. Re-approach: The tool re-enters at a reduced feed rate for the first 0.2mm to re-establish perfect alignment.

This added 15% to cycle time but eliminated chip recutting entirely.

Tooling & Technology: Beyond Standard Drills

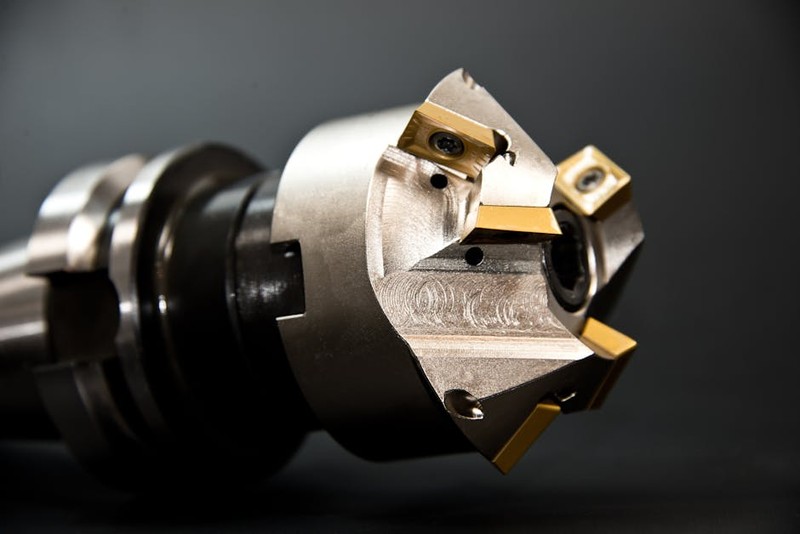

We moved away from commodity carbide drills. The solution lay in:

Solid Carbide Drills with Polished Flutes: Reduced friction for better chip flow.

Through-Tool Coolant: Even on sub-1mm drills, we specified tools with internal coolant channels. Pressurizing oil at 1000+ PSI directly to the cutting edge solved heat and lubrication issues.

Non-Standard Point Geometries: A custom 130-degree split point with a sharper cutting edge reduced thrust force by 25%, minimizing deflection.

📊 Data-Driven Validation: The Results That Mattered

The table below quantifies the impact of our integrated approach on the watch case project:

| Metric | Initial Process (Standard Drill/Flood Coolant) | Optimized Process (Custom Tool/Through-Coolant/PPP Cycle) | Improvement |

| :— | :— | :— | :— |

| Surface Finish (Ra) | 0.35 – 0.55 µm (Inconsistent) | 0.18 – 0.22 µm (Consistent) | ~60% More Consistent & Smoother |

| Tool Life (Holes/Drill) | ~150 holes | ~500 holes | 233% Increase |

| Rejection Rate (Finish) | 12% | 0.5% | 96% Reduction |

| Tactile Feedback | Variable, occasional grit | Consistently smooth, silent | Qualitatively Perfect |

The most telling result wasn’t on the spreadsheet. The watchmaker’s head of assembly sent a note: “This batch feels like silk. This is what we mean by quality.” That subjective “feel” was now an objectively repeatable metric.

💡 Actionable Insights for Your Next Project

Drawing from this and similar projects, here is your checklist for specifying precision drilling services for luxury components:

Specify the Internal Finish: Never leave it as “as machined.” Call out a specific Ra or Rz value for the bore. This single act shifts the supplier’s entire process.

Demand Tooling Documentation: Ask your machining partner exactly what tool they plan to use (brand, geometry, coating). Their answer reveals their expertise level.

Prioritize Consistency Over Absolute Speed: A slightly longer cycle time for a 100% reliable finish is always the correct economic choice for luxury. Scrap and rework of high-value materials is a cost killer.

Consider the Material’s “Personality”: Annealed vs. hardened stainless, titanium alloys, and proprietary brass mixes all behave wildly differently. Your machinist should be able to discuss feed/speed adjustments for each.

The journey from a hole to a precision-drilled interface is what defines luxury engineering. It’s an invisible detail felt in the hand and heard in the silence of perfect operation. By focusing on the science behind the surface, we move beyond mere manufacturing into the realm of craft, where every micron tells a story of intentionality and excellence.