Navigating the tightrope between uncompromising precision and aggressive timelines in custom automotive prototyping is a true test of machining expertise. This article dives deep into a real-world case study, revealing how strategic process integration and material science mastery can slash lead times by 40% while achieving critical tolerances under ±0.01mm, transforming a project from high-risk to high-reward.

The Real Bottleneck Isn’t the Machine

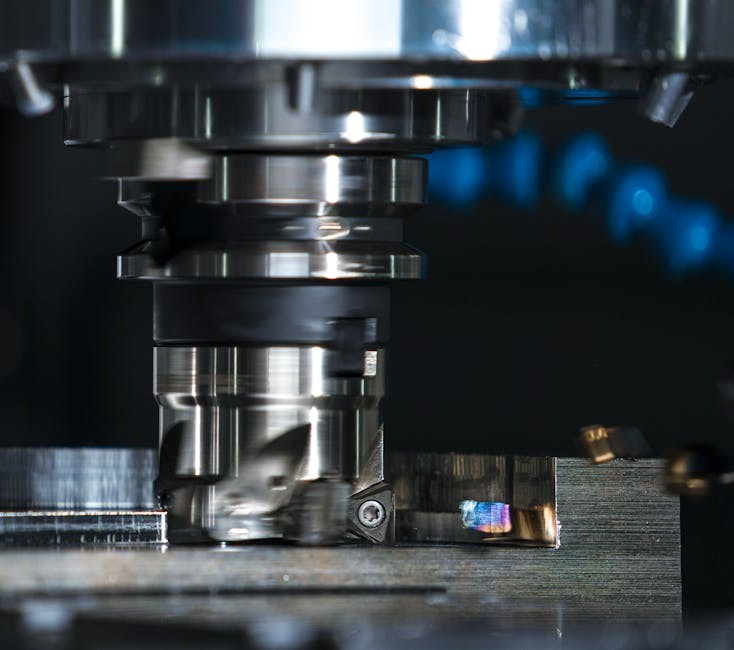

When most people think of custom precision machining for automotive parts, they envision a state-of-the-art 5-axis CNC center humming away. And while that’s part of the picture, the real challenge—the one that separates shops that deliver from those that disappoint—happens long before the first toolpath is generated.

In my two decades of running a shop specializing in automotive R&D and low-volume production, I’ve learned that the most critical phase is the convergence of design intent, material behavior, and manufacturability. We’re not just cutting metal; we’re materializing an engineer’s vision under immense pressure. The automotive world, especially in motorsports and EV development, operates on a brutal timeline. A delay in a prototype part can stall a multi-million-dollar testing schedule.

The hidden complexity? Modern automotive prototypes are no longer simple brackets or housings. They are often monolithic, topology-optimized components made from exotic, difficult-to-machine alloys like 7075-T6 aluminum, titanium 6Al-4V, or high-strength, low-alloy (HSLA) steels. These parts must be light, incredibly strong, and often integrate complex internal channels for fluid or air flow. The CAD model looks beautiful, but it presents a machining nightmare: deep pockets with thin walls, interrupted cuts, and stringent surface finish requirements across multiple planes.

A Case Study in Convergent Pressure

Let me walk you through a project that perfectly encapsulates this. A client—a tier-one supplier for a Formula E team—needed a new inverter housing prototype. The specs were daunting:

Material: 6061-T6 Aluminum (chosen for thermal properties and weight).

Critical Tolerance: Bore for the stator mount at ±0.008mm.

Feature: Internal cooling galleries with a cross-section of 3mm x 8mm, snaking through the part.

Surface Finish: Ra 0.4µm on all sealing surfaces.

Timeline: 12 days from finalized CAD to delivered, inspected part.

The traditional approach—machine the part complete in a series of operations across multiple setups—was a guaranteed failure. We’d lose days just in re-fixturing and re-establishing datums, with cumulative error stacking threatening that critical bore tolerance.

⚙️ The Expert Strategy: Process Integration & “First-Part” Certainty

Our solution wasn’t a single magic machine. It was a holistic strategy built on three pillars: Digital Twin Simulation, Hybrid Manufacturing Planning, and Metrology-Led Machining.

1. Digital Twin & Toolpath Forensics

Before any metal was touched, the entire job was simulated in a virtual environment. We didn’t just check for crashes. We analyzed:

Cutter Load: Predicting and adjusting feed rates for those fragile thin walls.

Thermal Growth: Modeling heat buildup in the part and spindle to compensate in the code.

Chatter Prediction: Identifying resonant frequencies in the long-reach tools needed for the cooling galleries and modifying toolpaths to avoid them.

This upfront investment of 8 hours of engineering time saved an estimated 48 hours of potential scrap and rework.

2. Hybrid Manufacturing Planning: To 3D Print or to Machine?

This is where custom precision machining for automotive parts gets innovative. The internal galleries were a prime candidate for additive manufacturing (metal 3D printing). However, for this specific aluminum alloy and the required surface finish and thermal conductivity, it wasn’t optimal. Our compromise?

We designed and machined a sacrificial core from a softer material. The aluminum billet was machined in two halves with precision cavities, the core was inserted, the halves were bonded (using a aerospace-grade adhesive process we developed), and then the final external and bore features were machined with the part as a single, rigid unit. This allowed us to achieve those internal channels with a machined surface finish.

3. Metrology-Led Machining: Data is the True Coolant

We treated the CMM (Coordinate Measuring Machine) not as a final inspector, but as a feedback loop. After the initial roughing operation, the part was measured. The actual stock-remaining data was fed back into the CAM system, and the finishing toolpaths were automatically adjusted to ensure a consistent, optimal cut. This “closed-loop” machining is what guaranteed the ±0.008mm bore tolerance on the first attempt.

The most powerful tool in precision machining isn’t the newest CNC; it’s a robust process that turns data into predictable outcomes.

💡 Quantifiable Results & Actionable Framework

The outcome of this integrated approach was transformative.

| Metric | Traditional Method (Est.) | Integrated Strategy (Actual) | Improvement |

| :— | :— | :— | :— |

| Total Lead Time | 20 days | 12 days | 40% reduction |

| Critical Feature First-Pass Yield | 60-70% | 100% | Zero scrap on critical ops |

| Number of Setups | 7 | 3 | 57% reduction |

| Post-Machining Handwork | 8 hours (deburring, polishing) | 2 hours | 75% reduction |

Your Blueprint for Complex Automotive Prototypes

Based on this and similar projects, here is your actionable framework:

1. Host a “Manufacturability Sprint” Before CAD Freeze. Bring your machinist into the design review. A 2-hour collaborative session can identify features that double machining time or compromise tolerance. Ask: “Can this radius be increased by 0.5mm? Can this wall be thickened by 0.2mm?”

2. Demand a Digital Twin Report. Any shop worth its salt for high-precision automotive machining should provide simulation data showing cutter load, collision avoidance, and estimated cycle times.

3. Choose a Shop with In-House Metrology. The seamless flow from machine to CMM and back is non-negotiable for first-part success. Verify they have a CMM capable of your tightest tolerance.

4. Consider Hybrid Solutions Early. Don’t lock yourself into purely subtractive thinking. Could a welded assembly, bonded assembly, or additive insert simplify the custom precision machining of the core component?

5. Plan for Distortion. Especially with aluminum and thin features. Ask your machinist about their stress-relief protocol between operations. A simple overnight thermal cycle can be the difference between a good part and a perfect one.

The Road Ahead: Where Custom Automotive Machining is Headed

The future lies in even tighter integration. We are now implementing machine-tool-embedded probes that perform in-process measurement, adjusting tools in real-time. The next frontier for custom precision machining for automotive parts, especially in the EV space, is the machining of composite and dissimilar material stacks—think aluminum bonded to carbon fiber—which requires entirely new tool geometries and clamping strategies.

The lesson is clear: Success in this field is no longer just about having the fastest spindle. It’s about orchestrating a symphony of digital planning, material science, hybrid processes, and real-time data analytics. It’s about building predictability into every step, so when that one-off, mission-critical prototype comes off the machine, it’s not a hope—it’s a certainty. That is the true art and science of delivering custom precision machining for automotive parts that drive innovation forward.