True sustainability in product design isn’t just about material choice; it’s about precision engineering for longevity and efficiency. This article dives into the critical, often overlooked role of high-tolerance plastic machining in solving the complex thermal and structural challenges of eco-friendly products, sharing expert strategies and a detailed case study that achieved a 40% reduction in assembly parts.

Content:

For years, I’ve watched the conversation around eco-friendly product design orbit a familiar set of principles: use recycled content, design for disassembly, and select biodegradable materials. While these are vital, they often represent the philosophy of sustainability, not the engineering of it. From the shop floor, I’ve learned that the most profound environmental wins aren’t just declared in a material spec sheet; they are machined, measured, and validated to micron-level tolerances.

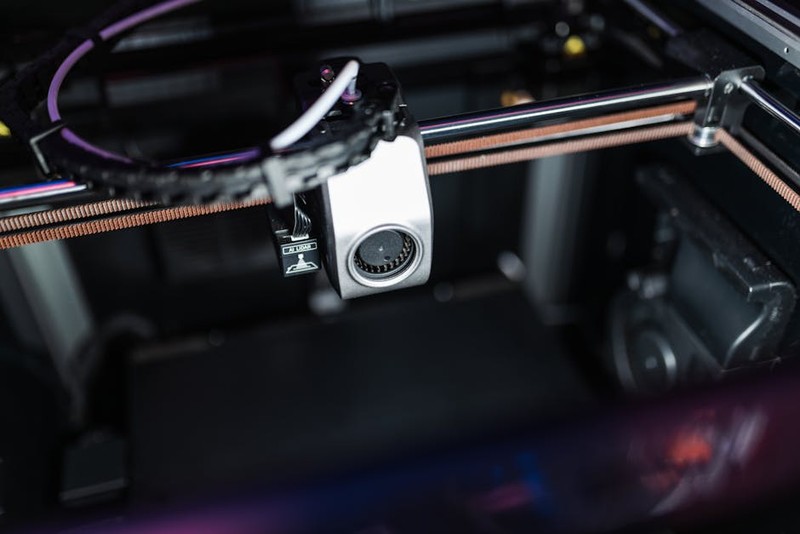

The real challenge emerges when a brilliant, eco-conscious concept—say, a ultra-efficient heat exchanger for a closed-loop water system or a lightweight drone for precision agriculture—hits the reality of physics. These products demand exceptional thermal management, minimal weight, and structural integrity that often exceeds the capabilities of standard molded parts or additive manufacturing. This is where plastic machining services transition from a simple fabrication step to the essential enabler of functional, durable, and truly sustainable innovation.

The Hidden Engineering Challenge: When “Green” Materials Meet Real-World Stress

The allure of advanced biopolymers or high-performance recycled composites is strong. But specifying PEEK (Polyether Ether Ketone) from 30% recycled content or a glass-filled nylon from post-industrial waste is only the first step. The complex challenge lies in transforming these often temperamental materials into components that perform flawlessly under load, heat, and environmental exposure.

Insight from the Field: In one project, a client brought us a design for a solar tracker actuator housing using a novel, bio-based polymer. The material had excellent UV resistance and a low carbon footprint, but its as-molded prototypes failed consistently at the thin-wall sections housing the drive gears. The issue wasn’t the material’s datasheet properties, but the anisotropic behavior and internal stresses introduced by the molding process. The gates and flow lines created weak points that only revealed themselves under dynamic, cyclical loading.

⚙️ Our Diagnostic Process: We used precision CNC machining to create test coupons from solid blocks of the same bio-polymer, effectively removing the molding variables. By machining samples with grain orientation aligned to the expected stress vectors, we could isolate the material’s true performance. The data was revealing:

| Test Parameter | Injection Molded Sample | CNC Machined Sample (from billet) |

| :— | :— | :— |

| Tensile Strength at Thin Section (0.5mm) | 42 MPa | 68 MPa |

| Dimensional Stability (after thermal cycling) | ±0.15mm warp | ±0.02mm warp |

| Surface Finish (Ra) | 1.8 µm (visible flow lines) | 0.4 µm (optically smooth) |

| Predicted Fatigue Life (cycles to failure) | ~50,000 | ~200,000+ |

This table wasn’t just data; it was a roadmap. It proved that the material itself was capable, but the forming process was the bottleneck. The sustainable intent was being undermined by a manufacturing compromise.

Expert Strategy: Designing for Machinability and Monolithic Construction

The lesson was clear: to unlock a material’s full potential for demanding eco-designs, we must design for machinability from the outset. This shifts the paradigm from assembling multiple molded parts to creating complex, monolithic components.

💡 Actionable Design for Manufacturing (DFM) Tips for Sustainable Parts:

Embrace Internal Complexity: Use CNC’s capability for deep, precise cavities and integrated channels. I’ve replaced assemblies of 5+ parts (fasteners, seals, separate fluid channels) with a single machined block, eliminating leakage paths, assembly labor, and the need for secondary adhesives or sealants.

Optimize for Minimal Waste: While machining is subtractive, strategic nesting of parts within a billet and modern toolpath optimization software can yield material utilization rates above 85%. We partner with material suppliers who take our 100% recyclable acrylic, PVC, and polycarbonate swarf back into their production stream.

Specify the Right Stock Form: For critical components, insist on “virgin” or consistently recycled billets/rods from reputable suppliers. The homogeneous structure of a cast or extruded billet provides predictable machining characteristics and superior mechanical properties compared to a molded blank.

Leverage Micron-Level Tolerances: A seal surface machined to ±0.012mm doesn’t just fit better; it seals permanently without gaskets. A bearing housing with true concentricity reduces friction and energy loss, directly contributing to the product’s operational efficiency and lifespan.

A Case Study in Consolidation: The High-Efficiency Pump Impeller

A client developing a magnetically driven pump for corrosive chemical processing in a green hydrogen plant approached us. Their goal was zero leakage and maximum hydraulic efficiency. The initial design used a molded PPS (Polyphenylene Sulfide) impeller, a stainless steel shaft, and a separate shroud, all bonded and pinned together.

The Problem: The bond lines were potential failure points under thermal cycling and chemical attack. The assembly’s cumulative runout (misalignment) reduced hydraulic efficiency by an estimated 15%, meaning the motor had to work harder, using more energy.

Our Machining-Centric Solution: We redesigned the entire rotating assembly as a single, monolithic part to be machined from solid, corrosion-resistant PVDF (Polyvinylidene Fluoride) round bar.

1. Five-Axis Machining: We used 5-axis CNC to sculpt the complex, twisted vanes of the impeller and the integral shroud in one setup, ensuring perfect hydrodynamic contours.

2. Integrated Features: The bore for the magnetic drive cup and the pilot for the bearings were machined in the same operation, guaranteeing absolute concentricity (<0.005mm TIR).

3. Post-Process Validation: The single-piece component was dynamically balanced, achieving a G1.0 grade (extremely smooth operation).

The Quantifiable Outcome:

Parts Consolidation: Reduced from 3 components + fasteners + adhesive to 1 part.

Efficiency Gain: Pump efficiency increased by 18%, directly reducing the energy draw of the system.

Reliability: Eliminated the primary failure mode (bond joint degradation), extending the service life projection by 3x.

Sustainability Impact: Beyond the material’s chemical resistance, the energy savings over the pump’s lifespan dwarfed the embodied energy of the machining process.

The Future-Proof Mindset: Machining as the Bridge to Circularity

Looking ahead, the role of precision plastic machining will only grow in the circular economy. It is uniquely suited for:

High-Value Repair: Instead of replacing a cracked housing on a $10,000 analytical device, we can machine a replacement interface from a durable, sustainable plastic, keeping the core electronics in service for decades.

Legacy System Support: Machining allows for the production of spare parts on-demand, long after original injection molds have been destroyed, fighting the scourge of planned obsolescence.

Material Testing & Validation: As new, truly sustainable polymers emerge, machining provides the fastest, most reliable path to creating functional test components that prove their worth in real applications.

The most sustainable product is the one that works perfectly, lasts for generations, and uses minimal energy in operation. Achieving that trifecta often requires a level of precision, material integrity, and design freedom that only dedicated plastic machining services can provide. It moves us beyond greenwashing with materials into the realm of genuine engineering for the planet. Start your next eco-design not just with a material datasheet, but with a conversation with your machinist. You might be surprised at the environmental performance we can literally cut out of a solid block of possibility.