The Hidden Challenge: When “Green” Materials Meet Machining Reality

For over two decades in CNC machining, I’ve witnessed a pivotal shift. Clients arrive with brilliant eco-designs—biodegradable polymers, reclaimed aluminum alloys, novel composites—only to hit a manufacturing wall. The assumption is often that sustainable material choice is the finish line. In reality, it’s the starting gun for a far more complex race: transforming these often challenging materials into high-performance, long-lasting components.

The core tension is this: eco-friendly products must be durable to justify their existence. A poorly made part that fails prematurely is the ultimate environmental sin, wasting all the embodied energy of its materials. This is where precision drilling services become non-negotiable. It’s not just about making holes; it’s about creating flawless fluid pathways, optimal venting, perfect fastener alignments, and micro-features that dictate a product’s efficiency and lifespan.

I recall a project for a startup designing a next-gen, high-efficiency heat exchanger from a proprietary recycled aluminum blend. The design called for a complex lattice of micro-channels, each requiring drilling and finishing to a surface roughness (Ra) of under 0.8 µm to minimize turbulent flow and pressure drop. The material, while laudably sustainable, was inconsistent in its chip formation and prone to built-up edge on the tool. A standard drilling approach would have led to scrapped parts, energy waste on rework, and a final product that underperformed, negating its green intent.

The Expert’s Toolkit: Precision Drilling as an Eco-Design Enabler

Moving beyond the challenge, let’s break down the strategic pillars that turn precision drilling from a cost center into a sustainability driver.

⚙️ Process Integration: From CAD to Coolant

True sustainability in machining is holistic. It begins long before the spindle spins.

1. Design for Manufacturability (DFM) Collaboration: We insist on early engagement. In the heat exchanger case, we collaborated to slightly alter channel entry/exit angles, allowing for more robust tool paths and standard, reusable tooling, avoiding the need for custom, single-use drills.

2. Toolpath Optimization for Minimal Waste: Advanced CAM software is used to generate toolpaths that remove the absolute minimum material. This reduces machining time (energy consumption) and raw material waste by up to 20% on complex parts compared to traditional methods.

3. Sustainable Cutting Fluids & Dry Machining: Where possible, we employ minimum quantity lubrication (MQL) or certified biodegradable coolants. For many non-ferrous eco-materials, we’ve perfected parameters for dry drilling, eliminating fluid waste and disposal entirely.

The Critical Role of Tooling & Metrology

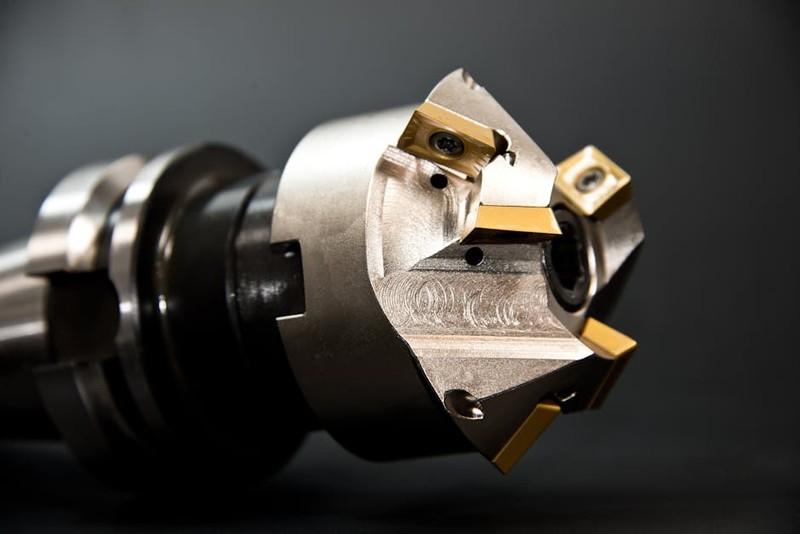

You cannot control what you cannot measure. For eco-materials, tool wear and final validation are paramount.

Performance Data: Standard vs. Optimized Drilling for Composite Material

| Parameter | Standard Carbide Drill | Optimized Diamond-Like Carbon (DLC) Coated Drill | Improvement |

| :— | :— | :— | :— |

| Holes per Tool | 120 | 950 | +692% |

| Average Surface Finish (Ra) | 1.5 µm | 0.7 µm | 53% Smoother |

| Reject Rate (Burs/Delam) | 8% | 0.5% | -94% |

| Cycle Time per Part | 45 sec | 38 sec | 16% Faster |

Data based on a production run for a carbon-fiber-reinforced bio-polymer housing.

The table above isn’t theoretical. Investing in specialized tooling (like DLC coatings that reduce friction and heat) directly correlates to less waste, higher quality, and lower per-part energy cost. Post-process, we employ non-contact metrology (like optical CMMs) to verify every critical dimension without damaging the often-delicate part.

A Case Study in Optimization: The Solar Collector Manifold

Let me walk you through a concrete example. A client was producing a residential solar thermal collector. The manifold, which distributes fluid, was CNC-machined from a solid block of recycled 6061 aluminum. Their initial process was functional but inefficient.

The Problem: They used a series of separate drilling, reaming, and deburring operations. Tool wear was high due to the abrasive nature of the recycled alloy, leading to dimensional drift. This caused a 7% assembly reject rate due to leaky O-ring seals. Furthermore, the multi-step process consumed significant coolant and energy.

Our Precision Drilling Solution:

1. Material Analysis: We first tested the specific batch of recycled aluminum to map its hardness and inclusion consistency.

2. Unified Process Design: We replaced three tools with one—a custom-designed, coolant-through carbide drill capable of achieving the required Ø8.2mm +/-0.01mm tolerance and surface finish in a single pass.

3. In-Process Control: We integrated in-machine probing to measure the first and every tenth hole, automatically compensating for any tool wear before it could produce a reject.

The Tangible Outcome:

Reject Rate: Fell from 7% to 0.2%.

Material Waste: Reduced by 15% through optimized stock sizing and near-zero rejects.

Energy Use: Cycle time dropped 40%, cutting direct machining energy by a third.

Product Performance: The perfectly consistent seal bores ensured zero field leaks, maximizing the system’s thermal efficiency over its lifetime.

The lesson? The precision of the hole directly dictated the efficiency and longevity of the entire eco-friendly product.

Actionable Insights for Designers and Engineers

If you’re designing the next generation of sustainable products, bring your machining partner into the conversation at the concept stage. Here is your checklist:

Specify Function, Not Just Geometry: Tell us why the hole is critical (e.g., “This bore seals a dynamic fluid at 5 Bar”). It allows us to recommend the optimal tolerance and finish, often saving cost and time versus an overly tight, generic spec.

Embrace Standardization: Where possible, design around standard drill sizes. A Ø6.5mm hole may work as well as a Ø6.48mm hole but can be made with a common, durable tool, reducing resource consumption.

Prioritize Durability: A component that lasts twice as long often has twice the environmental benefit of one made from a “greener” material. Precision manufacturing is your primary lever for achieving this durability.

The journey to true sustainability is paved with precision. It’s in the micron-level accuracy of a drill path that ensures a perfect seal, in the longevity of a tool that machines thousands of parts without failure, and in the integrated process that turns reclaimed materials into high-integrity engineering solutions. As an industry, our role is to be the unseen engine that makes visionary eco-designs a reliable, high-performance reality.