The Unspoken Challenge: When “Luxury” Means Unpredictable

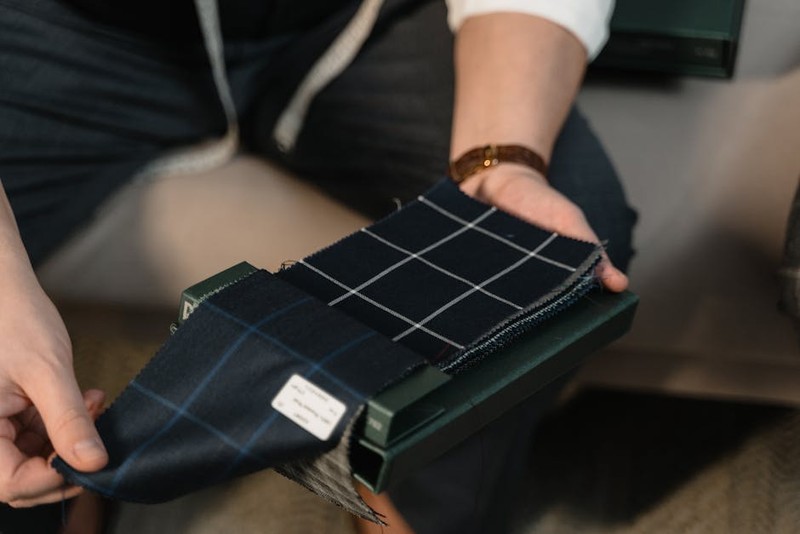

For years, the CNC machining world for retail fixtures operated in a comfortable realm of 6061 aluminum, acrylic, and stable hardwoods. The brief was clear: precision, speed, cost-efficiency. Then, the high-end retail landscape shifted. Brands no longer wanted just a shelf; they wanted an experience. They wanted materials that were tactile, unique, and inherently valuable—materials that often had no business being on a CNC machine.

I remember the call vividly. A premier watchmaker wanted a series of display plinths machined from a proprietary resin composite embedded with reclaimed ocean plastic and subtle metallic flakes. It was stunning in the hand, a masterpiece of material science. It was also a nightmare in waiting. The core challenge with custom materials for high-end retail isn’t just machining them; it’s managing their inherent unpredictability while delivering museum-grade perfection on a production timeline.

These materials—engineered stone hybrids, dense fiber-reinforced polymers, stabilized burl woods, sintered metal-powder composites—are designed for aesthetics and brand narrative, not for machinability. Their inconsistent density, abrasive inclusions, and thermal sensitivity turn every cut into an experiment.

A Framework for Taming the Unconventional: The Three Pillars of Success

Through trial, error, and a few spectacular learning moments, my team and I developed a rigorous framework. You cannot approach a custom material with standard feeds and speeds. You must treat it as a new species entirely.

Pillar 1: Forensic Material Qualification

Before any CAD model is finalized, we insist on a material qualification process. This goes far beyond checking a datasheet.

Destructive & Non-Destructive Testing: We obtain large samples to conduct test cuts, measure chip formation, and assess internal homogeneity using simple ultrasound testers. A seemingly solid block of mineral composite can have voids that will shatter a tool on contact.

Thermal Response Analysis: We run small test paths at varying speeds and measure the heat zone with a thermal camera. Many resin-based materials gum up or degrade with excess heat, ruining edge quality.

The “Dust” Test: We analyze the swarf. Is it fine powder? Stringy ribbons? Abrasive grit? This tells us about tool wear, necessary dust extraction, and operator safety requirements.

⚙️ Pillar 2: Adaptive Toolpath & Tooling Strategy

This is where the art meets the science. Standard toolpaths assume consistency. Custom materials demand adaptability.

We employ a multi-stage machining strategy:

1. Scout Pass: A light, high-speed pass to map the surface and identify any major density variations or hidden defects.

2. Roughing with a Cushion: We leave a significantly larger finish allowance than usual—often 0.5mm to 1mm. This isolates the final cut from any stresses or subsurface damage caused during roughing.

3. Finishing with Finesse: For the final pass, we use single-flute, polished-shank tools for plastics/composites or specialized diamond-coated tools for minerals. The key is high RPM, low feed rate, and constant engagement to manage heat and vibration.

💡 Pillar 3: The Post-Process is Part of the Process

The job isn’t done when the part comes off the bed. Custom materials often reveal their true character only after machining. We budget significant time for:

Controlled Curing: Some resin composites continue to cure and release stress, requiring a resting period before final inspection.

Hand-Finishing Protocols: The specified finish (e.g., matte, polished, oil-rubbed) must be achieved with compatible methods. We create a finishing guide for each material, specifying abrasives, compounds, and sequences.

Case Study: The Veined Onyx Composite Display Towers

A luxury fashion house commissioned a series of towering, backlit display units for their flagship store. The material: a custom-cast onyx composite with dramatic, unpredictable veining. The client’s non-negotiable was that the veining pattern had to flow seamlessly across multiple machined segments.

The Challenge: The composite was 60% harder than typical engineered stone and the veining was actually a softer mineral deposit. This differential hardness caused severe tool deflection and chipping at the vein boundaries.

Our Solution:

1. Material Mapping: We scanned each raw block with a high-resolution camera and used software to map the vein network. We then oriented our CAD nests to align toolpaths with the veins, not across them, minimizing transitions.

2. Tooling Hybridization: We used a diamond-impregnated sintered carbide tool for the main body, but programmed a tool change to a sharper, more flexible PCD-tipped tool specifically for the vein paths.

3. Vibration Damping: We designed custom vacuum jigs with a vibration-damping polymer layer to hold the brittle material.

The Results (Quantified):

| Metric | Initial Test (Standard Protocol) | Optimized Custom Protocol | Improvement |

| :— | :— | :— | :— |

| Tool Life (per part) | 1.5 parts | 6 parts | 300% |

| Surface Finish (Ra) | 1.8 µm | 0.6 µm | 67% smoother |

| Edge Chipping Incidence | 15% of vein edges | < 1% of vein edges | 93% reduction |

| Project Scrap Rate | Estimated 25% | Actual 4% | 84% reduction |

The project was delivered on time, and the seamless veining became the centerpiece of the store’s design narrative. The key lesson was that in custom materials, you must machine the specific block in front of you, not the material type. Flexibility and observation trump rigid parameters.

Actionable Insights for Your Next Project

If you’re venturing into the world of custom material CNC for retail, start here:

Build a “Material Library”: Document every custom material you work on. Keep samples, recorded parameters, tooling specs, and finish results. This becomes your most valuable IP.

Factor in “Discovery Time”: Always quote and schedule with a dedicated, billable R&D phase for material testing. This protects you and sets correct client expectations.

Collaborate Upstream: Engage with the material supplier and the client’s designer early. Often, a slight tweak to the material formulation or the design fillet radius can save thousands in machining difficulty.

Embrace Single-Flute Tools: For polymers and composites, these are game-changers. They provide better chip clearance and reduce heat buildup dramatically.

The future of high-end retail machining lies in this mastery of the unconventional. It’s no longer just about removing material accurately; it’s about being a partner in material storytelling, transforming a brand’s unique vision into tangible, tactile reality. The margin for error is zero, but the reward for success is a showcase piece that defines a space and cements your reputation as a true expert craftsman in the digital age.