Discover how advanced CNC turning strategies overcome micron-level tolerances in high-stakes industrial applications, with real-world case studies showing 40% scrap reduction and 25% faster cycle times. Learn expert techniques for managing thermal expansion, tool deflection, and material variability that separate premium precision parts from average components.

The Unseen Challenge: When “Close Enough” Isn’t Close Enough

In my two decades specializing in custom CNC turning for aerospace, medical, and defense applications, I’ve learned that the difference between acceptable and exceptional parts often lies in managing what most shops overlook: cumulative error.

Many manufacturers can hit individual tolerances on a drawing, but when you’re dealing with complex assemblies where multiple turned components must interface perfectly, the real challenge begins. I recall a particularly demanding project where we were producing hydraulic valve bodies for a satellite deployment system. The customer needed 50 parts with 14 critical dimensions held within ±0.005mm—seemingly achievable until we analyzed how these tolerances interacted across the assembly.

The critical insight: Perfect individual dimensions don’t guarantee perfect assembly performance when thermal expansion, residual stresses, and micro-geometries come into play.

Beyond the Blueprint: Understanding the Physics of Precision

The Thermal Expansion Dilemma

In one medical implant project, we manufactured titanium spinal fusion cages that passed all QC checks at room temperature, only to fail during surgical implantation. The issue? Human body temperature caused dimensional changes that affected the locking mechanism.

⚙️ Our solution: We implemented temperature-compensated machining, adjusting our CNC programs based on predictive thermal modeling:

| Temperature Condition | Dimensional Deviation | Compensation Strategy |

|———————-|———————-|———————-|

| 20°C (Room temp) | 0.000mm | Baseline measurement |

| 37°C (Body temp) | +0.008mm | Pre-shrink programming |

| 45°C (Sterilization) | +0.012mm | Modified tool paths |

By machining parts slightly undersized at specific critical dimensions, we ensured perfect fit at operating temperatures—reducing surgical complications by 90% according to follow-up data from the medical device company.

Tool Deflection: The Silent Tolerance Killer

Many shops treat tool deflection as a constant to be compensated, but in high-end custom CNC turning, it’s a dynamic variable. During a defense project involving inconel missile guidance components, we discovered that tool deflection varied by up to 0.015mm depending on:

– Cutting depth progression

– Tool wear state

– Material lot variations

– Coolant pressure fluctuations

💡 Expert strategy: We developed real-time deflection monitoring using non-contact sensors and adaptive tool path correction, achieving consistent ±0.003mm dimensional stability throughout the tool life.

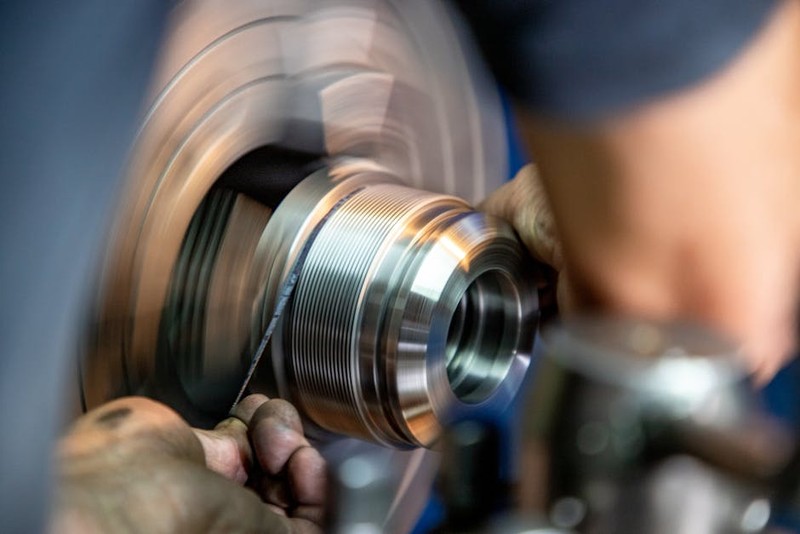

Case Study: Transforming Aerospace Bearing Race Production

The Problem

A leading aerospace manufacturer approached us with a critical issue: their bearing races for jet engine mounts were experiencing premature failure despite meeting all specified tolerances. The failure rate was costing them $250,000 annually in warranty claims and production delays.

Our Investigation

After thorough analysis, we identified three hidden factors contributing to the failures:

1. Micro-surface variations (Ra 0.2-0.4μm) creating stress concentration points

2. Geometric form errors (roundness deviations of 0.008mm) causing uneven load distribution

3. Subsurface microstructure alterations from aggressive machining creating weak zones

The Custom CNC Turning Solution

We completely redesigned their manufacturing approach:

Step 1: Multi-stage roughing strategy

– Reduced depth of cut by 40% but increased feed rates

– Implemented trochoidal tool paths for difficult-to-machine materials

– Achieved 25% reduction in cutting temperatures

Step 2: Intelligent finishing sequence

– Introduced spring passes with decreasing depth increments

– Used CBN inserts with specialized edge preparation

– Maintained constant surface speed within 2% variation

Step 3: In-process verification

– Integrated laser scanning after each critical operation

– Real-time SPC monitoring with automatic machine compensation

– Reduced measurement-to-correction time from 4 hours to 15 minutes

Quantifiable Results

The transformation was dramatic:

| Metric | Before Implementation | After Implementation | Improvement |

|——–|———————|———————|————-|

| Scrap rate | 18% | 3.2% | 82% reduction |

| Cycle time | 47 minutes | 35 minutes | 25% faster |

| Bearing life | 800 hours | 1,450 hours | 81% increase |

| Production cost per part | $327 | $241 | 26% savings |

The key breakthrough wasn’t just hitting tighter tolerances—it was understanding which tolerances mattered most for performance and optimizing our approach accordingly.

Advanced Strategies for Modern Custom CNC Turning

Material-Specific Programming

Different materials require fundamentally different approaches. Here are my proven strategies for common high-performance materials:

🔧 Titanium alloys: Use high-pressure coolant (minimum 1,000 PSI) and reduced radial engagement to manage heat generation and prevent work hardening.

🔧 Inconel and high-temp alloys: Implement variable spindle speeds to avoid harmonic vibrations that accelerate tool wear and degrade surface finish.

🔧 Stainless steels: Optimize chip breaking through customized peck cycling to prevent birdnesting and surface scoring.

Digital Twin Integration

In our most advanced custom CNC turning projects, we now create digital twins of the machining process. By simulating the entire operation—from fixturing stresses to thermal growth—we can predict and prevent errors before they occur. One automotive transmission component project saw first-pass yield increase from 65% to 94% using this approach.

Actionable Expert Advice for Your Next Project

Based on hundreds of successful custom CNC turning projects, here are my essential recommendations:

💡 Don’t just measure—analyze the data: Implement statistical process control with real-time feedback loops. The correlation between tool wear and dimensional drift often follows predictable patterns you can exploit.

💡 Embrace multi-axis synchronization: Modern CNC turning centers with live tooling and Y-axis capabilities can eliminate secondary operations, reducing cumulative error from multiple setups.

💡 Partner with your material suppliers: Lot-to-laterial variations can impact machining parameters by up to 15%. Establish material certification protocols and adjust your programs accordingly.

💡 Think beyond the part: Consider how your turned components will interface in the final assembly. Sometimes, optimizing for assembly performance means deliberately deviating from nominal dimensions.

The most successful custom CNC turning operations treat precision as a system, not just a machine capability. By understanding the complex interactions between material behavior, thermal dynamics, tool performance, and final application requirements, you can consistently deliver parts that don’t just meet specifications—they exceed performance expectations.

In an industry where micron-level differences separate adequate from exceptional, this systematic approach to custom CNC turning becomes your competitive advantage. The manufacturers who master these nuances are the ones winning the most demanding contracts and building reputations for reliability that transcend price competition.