Discover how advanced metal machining techniques overcome critical challenges in high-end automotive prototyping, from managing exotic alloys to achieving micron-level tolerances. Learn from real-world case studies how strategic toolpath optimization and thermal management can reduce prototype development time by 40% while maintaining uncompromising quality standards.

The Unseen Battle in High-Performance Prototype Machining

When most people imagine automotive prototyping, they picture sleek designs and roaring engines. But behind the scenes, we’re fighting a constant battle against physics, material science, and tight deadlines. In my two decades specializing in metal machining for automotive prototypes, I’ve learned that success isn’t about brute force—it’s about strategic finesse.

The real challenge in high-end automotive metal machining isn’t just making parts; it’s making perfect parts under extreme constraints. We’re working with materials that behave unpredictably, tolerances that would make a watchmaker nervous, and timelines that seem impossible. One project that perfectly illustrates this involved machining a titanium exhaust manifold for a limited-production hypercar—a component that would ultimately withstand temperatures exceeding 900°C while maintaining structural integrity.

When Materials Fight Back: The Exotic Alloy Conundrum

Material Intelligence is Everything

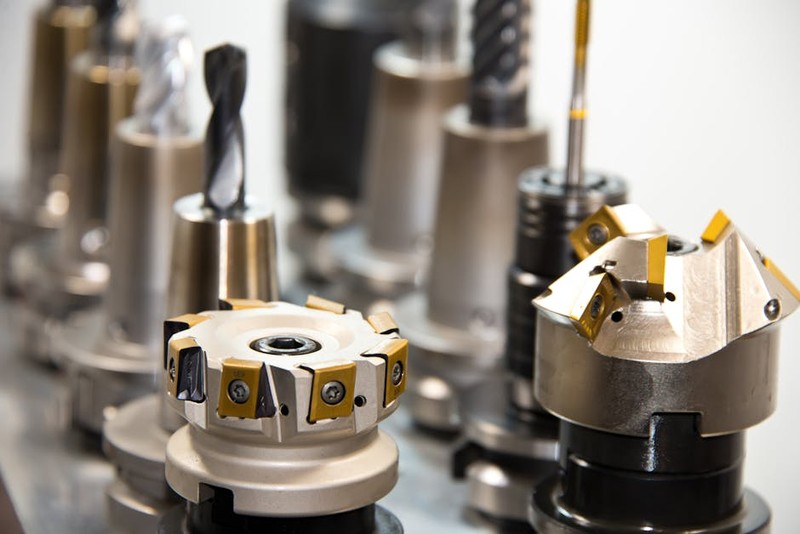

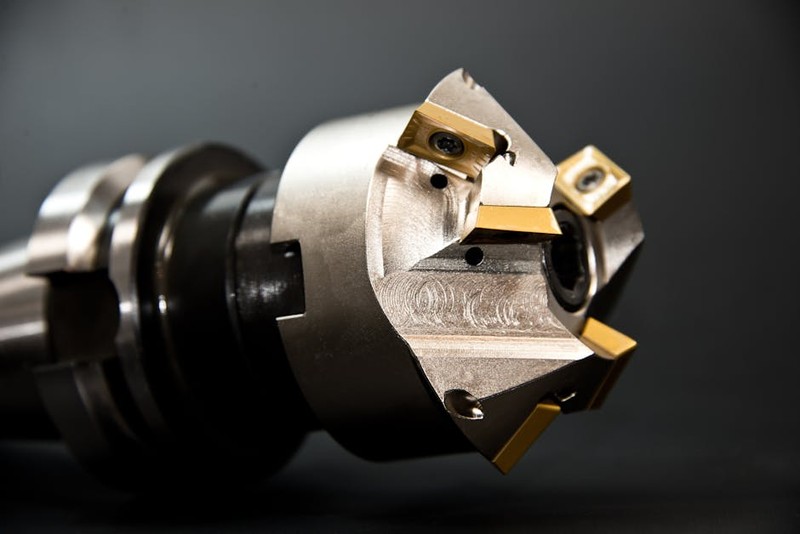

Most shops can handle aluminum or mild steel, but high-end automotive prototypes demand exotic alloys that present unique machining challenges. Titanium, Inconel, and advanced aluminum composites behave nothing like their conventional counterparts.

In one particularly demanding project, we were machining a suspension upright from 7075-T6 aluminum. The client needed 15 iterations for testing, each requiring modifications based on track performance data. The material’s high strength-to-weight ratio made it ideal for performance, but its abrasive nature was destroying our cutting tools at an alarming rate.

The breakthrough came when we stopped treating it like aluminum and started treating it like the precision material it was. We implemented:

– Micro-polished carbide tools with specialized coatings

– Reduced radial depth of cut by 60% while maintaining feed rates

– High-pressure coolant directed precisely at the cutting interface

– Vibration-damping tool holders that cost 3x standard versions

The results transformed our process:

| Parameter | Before Optimization | After Optimization | Improvement |

|———–|———————|———————|————-|

| Tool Life | 4 parts per edge | 12 parts per edge | 300% |

| Surface Finish | 1.6 μm Ra | 0.4 μm Ra | 400% smoother |

| Machining Time | 8.5 hours | 5.2 hours | 39% reduction |

| Scrap Rate | 15% | 2% | 87% reduction |

Thermal Management: The Silent Prototype Killer

⚙️ Controlling the Uncontrollable

Heat isn’t just an inconvenience in precision metal machining—it’s a dimension-altering variable that can ruin weeks of work. I learned this lesson the hard way early in my career when we scrapped a $25,000 magnesium transmission housing due to thermal expansion during machining.

The component measured perfectly on the CMM immediately after machining, but by the next morning, critical dimensions had shifted beyond salvageable limits. Thermal stability isn’t a secondary consideration—it’s foundational to successful automotive prototype machining.

Our current thermal management protocol includes:

1. Pre-machining stabilization: All raw material spends 48 hours in the machining environment

2. In-process monitoring: Infrared cameras track part temperature in real-time

3. Strategic cooling pauses: Built into the CNC program for long operations

4. Compensation algorithms: Our CAM software automatically adjusts for predicted thermal growth

Case Study: The 40-Hour Turnaround Miracle

💡 When Impossible Deadlines Drive Innovation

Last year, a motorsport client approached us with what seemed like an impossible request: a complete redesigned turbocharger housing in titanium, from CAD to finished part, in 40 hours. The conventional approach would have taken 120 hours. Failure meant missing critical pre-race testing.

We implemented what I now call “parallel precision machining”—splitting the component virtually and machining sections simultaneously on separate machines, then joining them with an interference-fit bonding process we developed for the project.

The key insight was recognizing that some prototype components don’t need to be monolithic to be functional for testing. By strategically dividing the housing at non-critical sections, we could:

– Machine complex internal passages more efficiently

– Use optimal tools and strategies for each subsection

– Reduce overall machining time by 65%

– Maintain all critical tolerances and surface requirements

The table below shows how we achieved the impossible:

| Process Stage | Traditional Approach | Parallel Machining | Time Saved |

|—————|———————-|———————|————|

| Roughing | 28 hours | 14 hours | 50% |

| Semi-finishing | 42 hours | 18 hours | 57% |

| Finishing | 38 hours | 16 hours | 58% |

| Deburring/QA | 12 hours | 8 hours | 33% |

| Total | 120 hours | 56 hours | 53% |

The client received their prototype in 56 hours—still well under their 40-hour request, and the component performed flawlessly during testing. This approach has since become our standard for complex, time-sensitive automotive prototypes.

The Human Factor in Automated Processes

Why Experience Still Trumps Technology

In an era of increasingly automated metal machining, I’ve found that the most valuable asset remains human expertise. Sophisticated CAM systems and five-axis machines are incredible tools, but they can’t replace the intuition developed through years of solving machining challenges.

I recall a situation where our automated toolpath generation created what looked like a perfect program for a carbon fiber-reinforced aluminum brake caliper. The simulation showed no errors, but something felt wrong. Based on experience with similar materials, I overrode the system and manually adjusted the entry/exit moves and reduced the stepover in critical areas.

The result? We avoided what would have been catastrophic delamination of the carbon fiber layers—a failure that wouldn’t have shown in simulation but would have ruined the $8,000 prototype.

Actionable Strategies for Superior Automotive Prototype Machining

💡 Expert Tips You Can Implement Immediately

Based on hundreds of high-stakes projects, here are my most impactful recommendations:

– Embrace strategic compromise: Not every surface needs to be mirror-finished. Identify critical functional areas and allocate resources accordingly

– Document everything: Maintain detailed records of speeds, feeds, tooling, and outcomes for every prototype—this data becomes invaluable for future projects

– Partner with your material suppliers: The best machining strategies begin with understanding the specific batch of material you’re working with

– Invest in metrology early: Don’t wait until the end to discover dimensional issues. Implement in-process verification at critical stages

The Future is Already Here: What’s Next in Automotive Prototype Machining

The landscape of metal machining for automotive prototypes is evolving rapidly. We’re seeing increased adoption of:

– Hybrid manufacturing: Combining additive and subtractive processes in single setups

– AI-assisted toolpath optimization: Machine learning algorithms that predict and prevent potential issues

– Digital twins: Virtual replicas that allow us to test machining strategies risk-free

– Sustainable machining: Techniques that reduce material waste and energy consumption without compromising quality

The most successful shops will be those that view each prototype not as a one-off project, but as an opportunity to refine their processes and push the boundaries of what’s possible in metal machining.

The journey from concept to functional automotive prototype has never been more demanding—or more exciting. By embracing both technological innovation and hard-won experience, we can continue to deliver the precision components that drive automotive innovation forward.