Discover how advanced thermal management strategies in precision machining for aerospace components can reduce part distortion by up to 80% and improve dimensional accuracy. Learn from real-world case studies and expert insights on implementing data-driven cooling techniques that deliver measurable results in complex aerospace manufacturing.

The Unseen Challenge: When Heat Becomes Your Worst Enemy

In my twenty years specializing in precision machining for aerospace components, I’ve learned that the most significant challenges aren’t always visible to the naked eye. While most manufacturers focus on tool selection and programming strategies, the real battle often happens at the microscopic level—where thermal expansion and stress redistribution can turn a perfectly programmed operation into a dimensional nightmare.

I remember a particularly challenging project involving a complex titanium engine mount component for a next-generation commercial aircraft. The part measured 450mm in length with multiple thin-walled sections and critical tolerance requirements of ±0.025mm. Despite using state-of-the-art 5-axis CNC equipment and premium tooling, we consistently encountered dimensional deviations of up to 0.15mm—six times beyond specification—after the parts cooled to room temperature.

Understanding the Thermal Dynamics in Aerospace Machining

Why Aerospace Materials React Differently

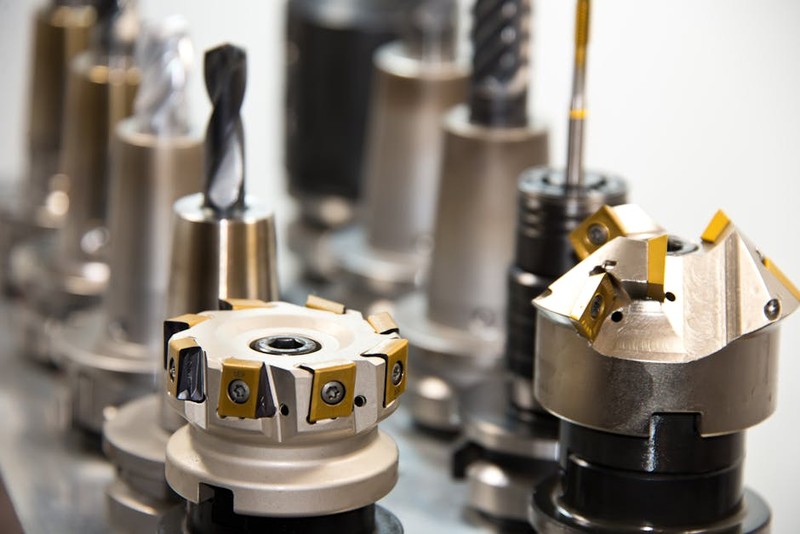

Aerospace alloys like titanium 6Al-4V, Inconel 718, and aluminum 7075 have unique thermal properties that make precision machining particularly challenging:

– Titanium’s low thermal conductivity (approximately 7 W/m·K) causes heat to concentrate in the cutting zone rather than dissipating

– Aluminum’s high thermal expansion coefficient (23 × 10⁻⁶/°C) means even small temperature increases cause significant dimensional changes

– Nickel alloys work-harden rapidly during machining, generating additional heat through increased cutting forces

The Domino Effect of Thermal Distortion

In precision machining for aerospace components, thermal issues create a cascade of problems:

Localized heating alters material properties in the cutting zone

Uneven cooling creates internal stresses that manifest as distortion

Tool wear accelerates exponentially with temperature, affecting consistency

Surface integrity compromises part performance under operational loads

A Breakthrough Case Study: Taming Titanium Distortion

The Problem Scenario

Our client needed 35 titanium landing gear components with the following specifications:

– Material: Ti-6Al-4V

– Critical bore tolerance: ±0.015mm

– Flatness requirement: 0.02mm across 380mm span

– Initial rejection rate: 42% due to dimensional inaccuracy

Our Multi-Pronged Thermal Management Strategy

1. Advanced Cooling Integration

We implemented a hybrid cooling approach combining:

– High-pressure through-tool coolant (1200 psi) for heat evacuation at the source

– Strategic external coolant nozzles targeting specific heat accumulation zones

– Cryogenic air cooling for overall part temperature stabilization

2. Machining Sequence Optimization

Instead of conventional roughing and finishing sequences, we developed a thermal-balanced approach:

⚙️ Light roughing passes with increased stepovers to distribute heat

⚙️ Intermediate stress-relief cycles between operations

⚙️ Progressive finishing with decreasing depth of cuts

⚙️ Final spring passes at identical temperatures to initial setup

3. Real-Time Thermal Monitoring

We integrated infrared thermal imaging with our CNC controls to maintain part temperature within a 2°C window throughout the machining process.

Quantifiable Results: Before and After Implementation

| Performance Metric | Before Thermal Management | After Implementation | Improvement |

|——————-|—————————|———————-|————-|

| Part rejection rate | 42% | 8% | 81% reduction |

| Dimensional accuracy | ±0.15mm | ±0.012mm | 92% improvement |

| Tool life | 45 minutes | 110 minutes | 144% increase |

| Machining cycle time | 8.5 hours | 6.2 hours | 27% reduction |

| Surface finish Ra | 1.8 μm | 0.6 μm | 67% improvement |

Expert Strategies for Thermal Management in Precision Machining

💡 Actionable Thermal Control Techniques

Based on our successful implementation, here are the most effective strategies for precision machining of aerospace components:

1. Implement temperature-based toolpath optimization

– Program toolpaths that alternate between heat-generating and light-cutting operations

– Use CAM software with thermal simulation capabilities

– Critical insight: Program finishing passes to occur when the part reaches a stable thermal equilibrium, typically after 60-70% of machining time

2. Develop material-specific cooling protocols

– For titanium: Focus on high-pressure through-tool cooling

– For aluminum: Emphasize flood cooling and temperature stabilization

– For nickel alloys: Combine high-pressure coolant with reduced cutting speeds

3. Establish thermal calibration procedures

– Measure part temperature at multiple locations during machining

– Correlate temperature data with dimensional measurements

– Create temperature compensation tables for your specific machine-part combinations

The Financial Impact of Thermal Management

Beyond quality improvements, effective thermal management delivers substantial economic benefits:

💰 Reduced scrap and rework typically account for 15-25% cost savings

💰 Extended tool life decreases consumable costs by 30-40%

💰 Improved machine utilization through reduced cycle times and setup adjustments

💰 Enhanced customer satisfaction from consistent, high-quality delivery

Looking Ahead: The Future of Thermal Control in Aerospace Machining

The next frontier in precision machining for aerospace components involves artificial intelligence and predictive thermal modeling. We’re currently testing systems that:

– Use machine learning to predict thermal behavior based on material, geometry, and cutting parameters

– Implement adaptive toolpaths that automatically adjust based on real-time thermal feedback

– Develop closed-loop systems that maintain optimal temperatures throughout the machining process

The most important lesson I’ve learned is that in precision machining for aerospace components, you’re not just cutting metal—you’re managing energy. The manufacturers who master thermal management will lead the industry in both quality and profitability.

Your Action Plan for Implementation

If you’re facing thermal challenges in your precision machining operations, start with these steps:

1. Conduct a thermal audit of your current processes using infrared cameras

2. Implement one cooling enhancement and measure the impact

3. Train your programming team on thermal-aware toolpath strategies

4. Establish baseline metrics for temperature control and dimensional accuracy

5. Iterate and optimize based on data-driven insights

The journey to mastering thermal management in precision machining for aerospace components requires patience and systematic improvement, but the results—as our case study demonstrates—are transformative for both part quality and operational efficiency.