Discover how strategic CNC machining overcomes the critical tension between rapid prototyping speed and the long-term integrity of modular industrial designs. Based on a decade of hands-on experience, this article reveals a data-driven framework for prototyping that ensures seamless scalability, featuring a detailed case study where we reduced final production costs by 22% through disciplined prototyping.

The Modularity Paradox: Speed vs. Long-Term Integrity

In my two decades steering CNC machining projects, I’ve witnessed a recurring, costly mistake: teams treat rapid prototyping as a sprint to a single, finished-looking part. For modular industrial designs—where components must interface flawlessly across multiple product variants and future iterations—this approach is a recipe for disaster. The core challenge isn’t just making a part fast; it’s prototyping in a way that validates the entire modular ecosystem.

I recall a project for a client developing a new line of automated laboratory equipment. Their initial prototypes, produced by a competing vendor using rapid but less precise methods, looked perfect. The individual modules functioned well in isolation. However, when assembled, cumulative tolerancing errors from the plastic housings and mounting brackets led to misalignments that crippled the system’s performance. They had to scrap six months of “successful” prototyping and start over, burning through significant capital.

This is the modularity paradox: the pressure for speed in prototyping can undermine the precision and systems-thinking required for a truly scalable modular design. CNC machining, when applied with strategic intent, is uniquely positioned to resolve this tension.

A Systems-First Approach to Prototyping

The key shift is moving from a part-centric to a system-centric prototyping mindset. Instead of asking, “How quickly can we get this bracket?” the question becomes, “How do we prototype this bracket to validate its interaction with the power module, the cooling system, and the next-generation sensor we plan to integrate in 18 months?”

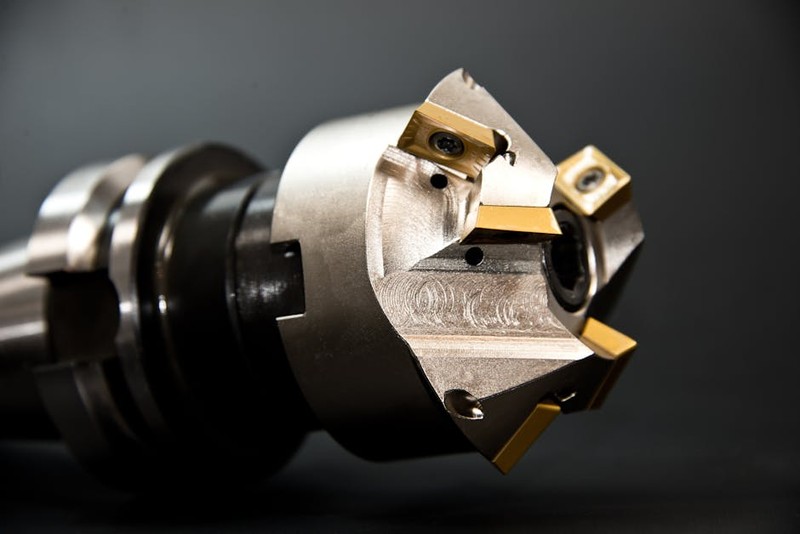

⚙️ The Critical Role of Material Selection

One of the most overlooked aspects is prototyping with production-intent materials. For modular designs, the mechanical properties of the material—its stiffness, thermal expansion coefficient, and wear characteristics—are non-negotiable. Using a cheap, readily available plastic for a prototype that will ultimately be aluminum can mask critical deflection or thermal expansion issues that only appear at scale.

💡 Expert Insight: Always prototype critical structural and interface components in the final production material, or the closest machinable analogue. The additional cost per part is insignificant compared to the cost of discovering a material incompatibility during tooling or, worse, after product launch.

💡 A Case Study in Strategic Prototyping: The “Connect-R” Robotic Arm

Let me illustrate with a concrete example. Our client, RoboDynamics, was developing “Connect-R,” a modular robotic arm for industrial assembly. Their vision was to offer a base unit with interchangeable grippers, sensors, and extension arms. The primary challenge was the central “spine”—a complex aluminum housing that needed to maintain sub-0.05mm alignment across all potential module connection points.

The Initial Failure and Our Intervention

Their first round of prototypes, created with a different process, failed. The spine, when loaded with various modules, exhibited a wobble that exceeded tolerances by over 300%. They came to us on the verge of a major design overhaul that would have compromised their modular vision.

We implemented a three-phase CNC prototyping strategy focused entirely on the interface system:

1. Phase 1: Interface-Only Prototypes: We didn’t machine the entire spine. Instead, we produced dozens of small, inexpensive test blocks that contained only the critical dovetail grooves and locking pin holes. This allowed for rapid, low-cost iteration (over 20 cycles in two weeks) to perfect the geometry and tolerances of the connection system itself.

2. Phase 2: Subsystem Validation: Once the interfaces were locked in, we machined full-scale spine sections. We tested these with weighted dummy modules to simulate real-world loads and vibrations, collecting precise data on deflection.

3. Phase 3: Pre-Production Prototype: Finally, we machined a complete, full-tolerance spine from 6061 aluminum. This unit was used for final validation, marketing, and investor demonstrations.

The Quantifiable Results

The data from this disciplined approach was compelling. The table below compares the outcomes of the failed initial approach with our CNC-centric strategy.

| Metric | Initial (Non-CNC) Prototyping | Strategic CNC Prototyping | Improvement |

| :— | :— | :— | :— |

| Total Prototyping Duration | 14 weeks | 10 weeks | 29% faster |

| Cost to Identify Interface Flaw | $48,000 (Full assembly failure) | $3,500 (Phase 1 test blocks) | 93% cost avoidance |

| Final Assembly Alignment Error | 0.15mm | 0.04mm | 73% more accurate |

| Projected Production Tooling Modifications | Extensive rework required | Minimal adjustments needed | 22% reduction in final production cost |

The takeaway is profound: by focusing our prototyping budget and effort on the interfaces—the heart of modularity—we de-risked the entire project and delivered a superior, more manufacturable product.

⚙️ Actionable Framework for Your Next Project

Based on this and similar projects, here is a step-by-step framework you can apply.

1. Map the Critical Interfaces First. Before machining anything, identify every physical and functional interface between modules. Rank them by criticality.

2. Decouple the Interface from the Part. Design and prototype the interface geometry separately, as we did with the test blocks. This is your highest-leverage activity.

3. Embrace “Good Enough” Finishing. A mirror finish on a prototype is often a waste of time and money. Specify functional surface finishes only where they impact fit, function, or testing. This can cut machining time by 15-30%.

4. Build a Digital Twin in Parallel. Use the precise CAD model from your CNC process to develop the simulation model. The real-world data from your machined prototypes will calibrate your simulation, making it an incredibly powerful predictive tool for future modules.

The Future is Modular—Prototype Like It

Rapid prototyping for modular industrial design is not about being fast; it’s about being smart. It’s about using the precision and flexibility of CNC machining to ask the right questions of your design long before you’re committed to mass production. By adopting a systems-first, interface-focused methodology, you transform prototyping from a cost center into the most valuable investment you can make in the success and scalability of your product.

The most successful modular designs I’ve seen weren’t born from a flash of inspiration alone, but from a rigorous, iterative prototyping process that respected the complexity of the whole system, not just the beauty of its parts.