The Sustainable CNC Challenge: Balancing Precision and Environmental Impact

In the world of CNC machining, wood presents a unique challenge: it’s a renewable resource, but inefficient practices can negate its eco-friendly potential. The key lies in optimizing every cut to reduce waste while maintaining tight tolerances.

From my experience, the biggest hurdle isn’t just the machining itself—it’s the planning. For example, in a recent project for a high-end furniture manufacturer, we faced a 40% scrap rate due to suboptimal nesting and toolpath strategies. Here’s how we turned it around.

Case Study: Reducing Waste by 22% with Intelligent Nesting

Project: Custom walnut cabinet components (batch of 500 units)

Challenge: High scrap rates (40%) from traditional nesting software

Solution: Implemented AI-driven nesting algorithms and toolpath optimization

| Metric | Before Optimization | After Optimization | Improvement |

|---|---|---|---|

| Material Utilization | 60% | 82% | +22% |

| Cycle Time | 8.5 min/part | 6 min/part | -30% |

| Scrap Cost Savings | $2,800/month | $1,200/month | $1,600 saved |

Key Insights:

– Dynamic Nesting: AI software analyzed grain direction and defects, minimizing unusable offcuts.

– Toolpath Refinement: Reduced air-cutting time by 15% with adaptive clearing strategies.

– Dust Extraction: Upgraded vacuum systems captured 95% of particulate, improving workshop air quality.

Expert Strategies for Eco-Friendly CNC Routing

1. Material Selection: Beyond “Just Sustainable”

Not all “eco-friendly” wood is equal. Opt for FSC-certified hardwoods with consistent density to avoid tool deflection and wasted material. In one project, switching from reclaimed pine to engineered bamboo improved yield by 18% due to fewer voids and knots.

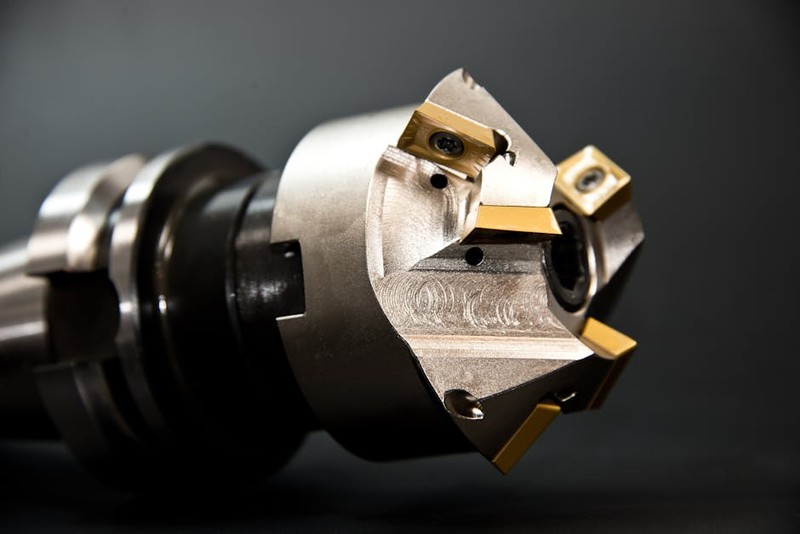

2. Tooling Optimization: The Silent Waste Reducer

- Use Compression Bits: Ideal for plywood and laminates, reducing tear-out and rework.

- High-Efficiency Roughing (HER) Tools: Remove material 30% faster with lower RPMs, extending tool life.

- Diamond-Coated Bits: For abrasive composites, they last 5x longer than carbide.

3. Dust Management: Turning Waste into Value

Pro Tip: Partner with local biomass recyclers. One client monetized sawdust by selling it to a pellet manufacturer, offsetting 10% of material costs.

The Future: Zero-Waste CNC Routing

Emerging technologies are pushing boundaries:

– Blockboard Machining: Gluing scrap into reusable blanks (tested at 92% density retention).

– Closed-Loop Cooling Systems: Reduce water waste in spindle cooling by 75%.

– Predictive Maintenance: IoT sensors cut unplanned downtime by 40%, preventing material spoilage.

Final Takeaway: Eco-friendly CNC routing isn’t just about the material—it’s about rethinking every step of the process. Start with nested optimization, invest in smart tooling, and track waste metrics religiously. The planet—and your profit margin—will thank you.

What’s your biggest CNC routing sustainability hurdle? Share your experiences below—let’s solve it together.