The Hidden Challenge: Why Plastic Panels Are Trickier Than They Seem

At first glance, CNC routing plastic panels might seem straightforward—softer than metal, easier to machine, right? Wrong. In my 15 years of CNC machining, I’ve found plastics like acrylic, polycarbonate, and PVC present unique challenges that can derail even the most experienced machinists.

Thermal Warping: The Silent Killer

Plastics are highly sensitive to heat buildup during routing. Unlike metals, which dissipate heat efficiently, plastics melt, gum up tools, or warp mid-cut. I’ve seen panels that measured perfectly post-machining only to deform hours later due to residual stress.

Key Insight:

– Low melting points: Acrylic melts at ~160°C, while tool friction can easily exceed this.

– Coefficient of thermal expansion: Plastics expand 5-10x more than metals, causing dimensional inaccuracies.

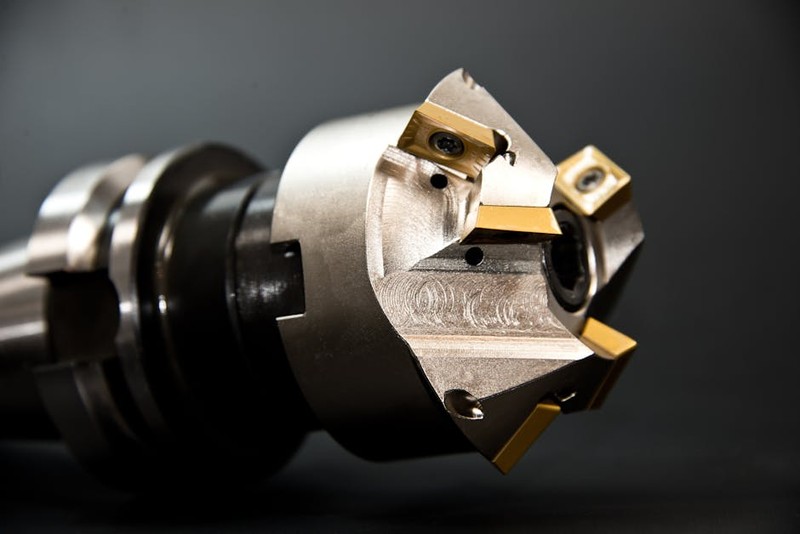

Tooling Pitfalls: Not All Bits Are Created Equal

Using a standard carbide end mill designed for metals? Prepare for melted edges and poor surface finishes. Plastics require:

– Up-cut vs. down-cut spirals: Down-cut bits compress material, reducing chipping on top layers.

– High rake angles: Sharper edges reduce heat generation.

– Polished flutes: Minimize friction and material adhesion.

A Case Study in Optimization: Reducing Scrap Rates by 22%

The Problem

A client needed 500 acrylic display panels with intricate cutouts. Initial runs had a 30% scrap rate due to warping and edge delamination.

The Solution

- Toolpath Optimization:

- Switched to climb milling to reduce tool pressure.

- Used trochoidal toolpaths to distribute heat evenly.

- Cooling Strategy:

- Air blast cooling (not mist!) to prevent moisture absorption.

- Reduced RPMs by 20% (from 18,000 to 14,400) to lower friction heat.

- Material Handling:

- Pre-stressed panels by annealing before machining.

- Used sacrificial backing to minimize vibration-induced cracks.

The Results

| Metric | Before Optimization | After Optimization |

|---|---|---|

| Scrap Rate | 30% | 8% |

| Edge Quality (Ra) | 3.2 µm | 1.6 µm |

| Cycle Time per Panel | 12 mins | 10 mins |

|

||

| Lesson Learned: Slower isn’t always worse. Reducing RPMs and optimizing toolpaths saved more time in rework than it added in machining. | ||

| — | ||

| ## Expert Strategies for Flawless Plastic Panel Routing | ||

| ### 1. Material-Specific Tool Selection | ||

| – For Acrylic: Use a single-flute O-flute bit for clean, melt-free edges. | ||

| – For Polycarbonate: A 2-flute spiral bit with a 10° rake angle prevents gumming. | ||

| ### 2. Heat Management Techniques | ||

| – Peck drilling: For deep holes, retract frequently to clear chips and cool the tool. | ||

| – Step-down increments: Limit depth of cut to 1x tool diameter to reduce heat concentration. | ||

| ### 3. Fixturing for Stability | ||

| – Vacuum tables: Ideal for thin panels, but ensure even suction to prevent stress. | ||

| – Custom jigs: Use soft jaws or rubberized clamps to avoid marring surfaces. | ||

| — | ||

| ## The Future of CNC Routing for Plastics | ||

| Emerging trends like cryogenic machining (using liquid CO2 to cool tools) and AI-driven adaptive toolpaths are pushing boundaries. In a recent trial, cryogenic cooling reduced tool wear by 40% on polycarbonate. | ||

| Final Takeaway: | ||

| Plastic panel routing demands a nuanced approach—balancing speed, heat, and tool geometry. By applying these strategies, you’ll turn a finicky process into a repeatable, high-quality operation. | ||

| — | ||

| What’s your biggest plastic routing challenge? Share your experiences below—let’s solve it together. |