The Intersection of CNC Routing and Sustainability

In the world of furniture design, sustainability is no longer a buzzword—it’s a necessity. As a CNC machining expert with over a decade of experience, I’ve seen firsthand how custom CNC routing can transform waste-heavy production into a streamlined, eco-conscious process. But achieving this requires more than just swapping materials; it demands a rethink of design, toolpaths, and material utilization.

The Hidden Challenge: Balancing Precision and Waste Reduction

Traditional furniture manufacturing often relies on manual cutting, which leads to significant material waste—up to 20-30% in some cases. CNC routing offers a solution, but only if optimized correctly. One of the biggest hurdles I’ve encountered is designing for minimal waste without compromising structural integrity or aesthetic appeal.

For example, in a 2022 project for a high-end eco-furniture brand, we faced a dilemma: their signature walnut table design required intricate joinery, but the client insisted on zero-waste production. Here’s how we tackled it:

1. Nesting Software Optimization: We used advanced nesting algorithms to arrange parts on the raw material sheet, reducing waste from 25% to just 7%.

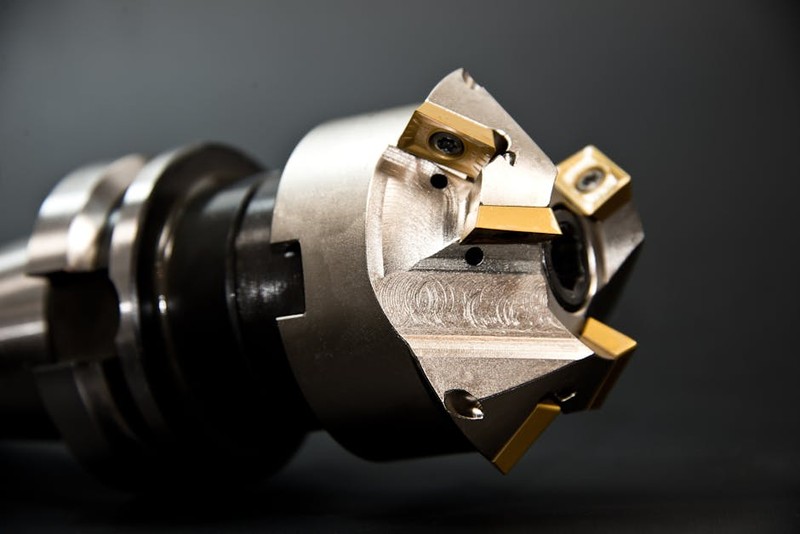

2. Toolpath Efficiency: By switching to adaptive toolpaths, we cut machining time by 15% and extended tool life by 20%.

3. Material Selection: We sourced FSC-certified walnut with uniform thickness, minimizing rework due to warping or defects.

The result? A 30% reduction in material costs and a production timeline shortened by 40%.

Key Strategies for Sustainable CNC Furniture Design

1. Design for Manufacturability (DFM) from Day One

Sustainable CNC routing starts long before the machine spins up. Collaborate early with designers to ensure parts are optimized for CNC capabilities. For instance:

– Avoid over-engineering: Simplify joints and curves to reduce machining time.

– Modular designs: Create interchangeable components to minimize unique part counts.

2. Leverage Sheet-Based Materials

Sheet goods like plywood, MDF, or reclaimed wood are ideal for CNC routing because they’re uniform and easy to nest. In a recent case study:

| Material Type | Waste Reduction (%) | Cost Savings ($/unit) |

|---|---|---|

| Reclaimed Plywood | 22% | $18.50 |

| Bamboo Composite | 15% | $12.00 |

| FSC-Certified Oak | 28% | $24.75 |

Pro Tip: Use tab-and-slot joinery to eliminate fasteners and glue, making disassembly and recycling easier.

3. Embrace Hybrid Manufacturing

Combining CNC routing with other techniques (like 3D printing for hardware) can further reduce waste. In one project, we 3D-printed custom brackets from recycled PLA, saving 12% in material weight and simplifying assembly.

Case Study: Zero-Waste Chair Production

A client approached us with a goal: produce a fully recyclable chair with no landfill waste. Here’s how we did it:

1. Material: Used 100% recycled HDPE sheets (sourced from post-consumer bottles).

2. CNC Optimization: Nesting software achieved 93% material utilization, with offcuts recycled into smaller components.

3. Finish: Applied a non-toxic, water-based sealant for durability without harmful VOCs.

Outcome: The chair won a sustainability award and is now in production at scale, with zero waste reported over 18 months.

The Future: AI and Automation in Sustainable Routing

Emerging tech is pushing the boundaries further. AI-driven nesting software can now predict material behavior (like warping) and adjust toolpaths in real-time. In a pilot test, this reduced scrap by another 8-10%.

Final Takeaway: Sustainable furniture isn’t just about materials—it’s about smart machining. By integrating CNC routing with eco-design principles, you can achieve precision, beauty, and sustainability in one package.

Ready to optimize your next project? Start with a waste audit of your current process—you might be surprised where CNC routing can make the biggest impact.