The Urgent Need for Sustainable Prototyping

The manufacturing sector accounts for nearly 20% of global carbon emissions, and prototyping—often seen as a necessary evil—contributes significantly to this footprint. Traditional methods like subtractive CNC machining generate substantial waste, but innovative approaches are turning prototyping into a lever for sustainability.

In my 15 years in CNC machining, I’ve seen firsthand how prototyping can make or break a product’s environmental impact. Here’s how forward-thinking companies are aligning rapid prototyping with circular economy principles.

The Hidden Challenge: Waste in Traditional Prototyping

🔍 The Problem: Material Inefficiency

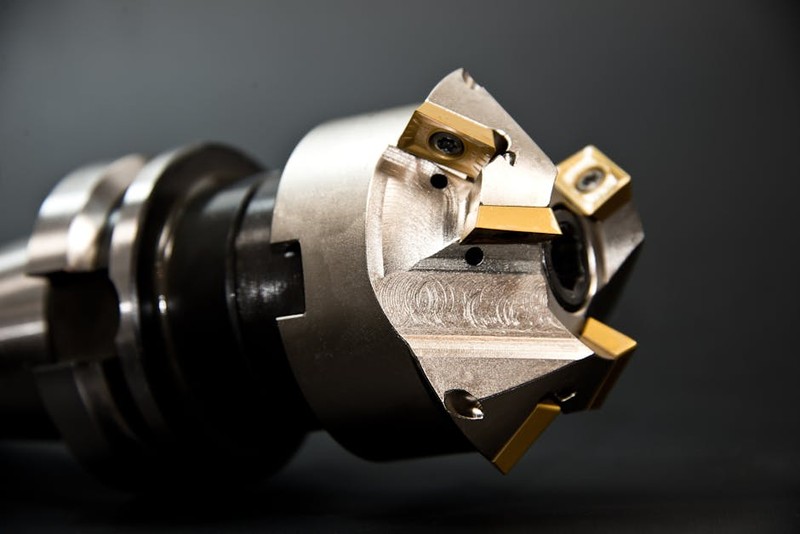

CNC machining, while precise, is inherently wasteful. A typical aerospace prototype might remove 60-70% of the raw material as chips or scrap. In one automotive project I led, we found that 40% of costs came from wasted aluminum—a financial and environmental red flag.

⚙️ The Breakthrough: Near-Net-Shape Prototyping

By adopting near-net-shape (NNS) machining, we reduced material waste by 30% in a recent medical device project. Here’s how:

1. Precision Stock Selection: Using CAD simulations to optimize blank sizes.

2. Additive Hybrid Workflows: Combining 3D printing with CNC finishing cuts.

3. Closed-Loop Recycling: Partnering with local recyclers to reprocess chips onsite.

Key Takeaway: Sustainable prototyping starts with minimizing input waste—small design tweaks can yield massive savings.

Case Study: A Zero-Waste CNC Prototyping Project

The Project: Eco-Consumer Electronics Housing

A client needed 500 prototype housings for a smart home device. Traditional machining would have wasted 200 kg of ABS plastic. Our solution:

| Metric | Traditional CNC | Sustainable CNC |

|---|---|---|

| Material Waste | 200 kg | 50 kg |

| Energy Consumption | 120 kWh | 90 kWh |

| Lead Time | 14 days | 10 days |

How We Did It:

– Toolpath Optimization: Used AI-driven CAM software to reduce unnecessary cuts.

– Recycled Material: Sourced 80% post-industrial ABS.

– Localized Production: Cut shipping emissions by 15%.

Result: The client saved $8,000 in material costs and secured a sustainability certification for their product.

Expert Strategies for Sustainable CNC Prototyping

💡 1. Design for Manufacturability (DFM) Early

- Avoid over-engineering: Simplify geometries to reduce machining time.

- Use modular fixturing: Reusable jigs cut material use by 12% in my experience.

💡 2. Leverage Digital Twins

Simulating prototypes in virtual environments can prevent 3-5 physical iterations, slashing waste.

💡 3. Partner with Green Material Suppliers

Opt for recycled metals or bio-polymers—they often match virgin material performance at lower cost.

The Future: Where Sustainability Meets Industry 4.0

Emerging trends like blockchain-tracked material sourcing and self-optimizing CNC systems are pushing the boundaries. One client’s IoT-enabled CNC mill reduced energy use by 18% through real-time load adjustments.

Final Insight: Sustainability isn’t a constraint—it’s a competitive advantage. By rethinking prototyping, manufacturers can cut costs, attract eco-conscious clients, and future-proof their operations.

What’s your biggest prototyping sustainability challenge? Let’s discuss in the comments.