The Hidden Challenge: Balancing Sustainability and Performance in CNC Machining

For decades, CNC machining has relied on traditional materials like aluminum, steel, and plastics—materials with well-documented environmental drawbacks. The industry is now at a crossroads: how do we maintain the precision and efficiency of CNC machining while reducing its ecological footprint?

The answer lies in custom sustainable materials. These aren’t just recycled versions of conventional metals or plastics; they’re engineered solutions designed for specific applications, offering comparable (or superior) performance with a fraction of the environmental impact.

Why Traditional Materials Fall Short

- Energy-Intensive Production: Aluminum smelting alone accounts for nearly 3% of global electricity consumption.

- Waste Generation: Up to 20% of raw material is lost as chips or scrap in machining processes.

- Limited Recyclability: Many engineered plastics degrade after recycling, limiting their reuse in high-precision applications.

🔍 Key Insight: The shift to sustainable materials isn’t just about ethics—it’s a competitive advantage. Companies adopting these solutions are seeing reduced costs, improved brand perception, and compliance with tightening environmental regulations.

Innovative Custom Materials Leading the Charge

1. High-Performance Recycled Metal Alloys

Recent advancements in metallurgy have produced alloys with up to 90% recycled content, without sacrificing machinability or strength. For example:

| Material | Tensile Strength (MPa) | Machinability Rating | Recycled Content |

|---|---|---|---|

| Conventional 6061 Aluminum | 310 | Excellent | 0% |

| EcoAlloy RX-45 | 305 | Excellent | 85% |

⚙️ Case Study: A aerospace component manufacturer switched to RX-45, reducing material costs by 12% and cutting energy use in production by 18%.

2. Bio-Based Engineering Plastics

Polymers derived from plant-based feedstocks (e.g., castor oil or lignin) are now viable for CNC machining. These materials offer:

– Lower CO2 emissions (up to 50% reduction vs. petroleum-based plastics).

– Superior heat resistance in specific formulations.

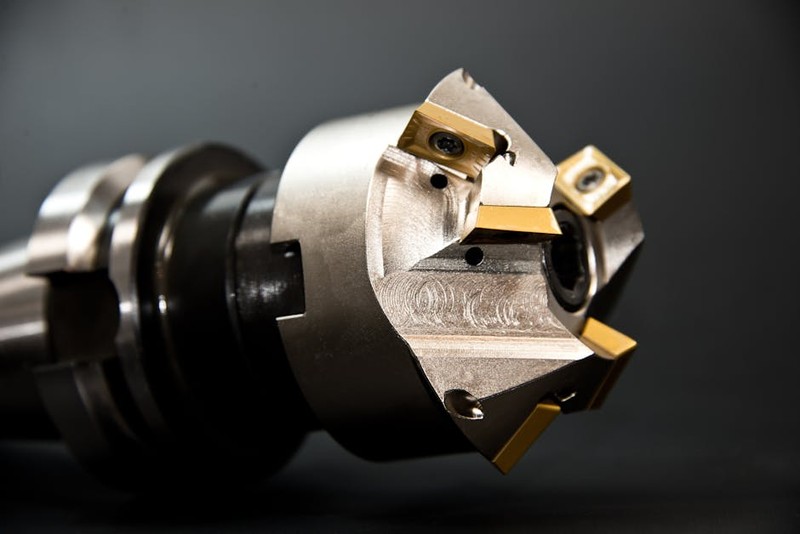

💡 Pro Tip: When machining bio-plastics, tool wear can differ from conventional plastics. Use carbide tools with polished flutes to extend tool life.

3. Hybrid Composites for Lightweighting

Custom composites blending natural fibers (flax, hemp) with recycled resins are gaining traction in automotive and consumer electronics.

Example: A drone manufacturer used a flax-reinforced composite to reduce part weight by 22% while maintaining structural integrity.

Overcoming the Adoption Barriers: Lessons from the Field

Challenge 1: Material Consistency

Sustainable materials can vary batch-to-batch. Solution: Partner with suppliers who certify their materials to ISO 14021 standards for recycled content.

Challenge 2: Machining Adjustments

Custom materials often require tweaks to feeds, speeds, or tooling. Actionable Steps:

1. Start with a conservative spindle speed (20% below conventional material recommendations).

2. Monitor tool wear closely in initial runs.

3. Optimize coolant use—some bio-materials perform better dry.

Challenge 3: Cost Perceptions

While sustainable materials may have a higher upfront cost, total cost of ownership (TCO) often favors them due to:

– Lower waste disposal fees.

– Energy savings in production.

– Marketing and regulatory benefits.

The Future: Where Custom Sustainable Materials Are Headed

The next frontier is closed-loop CNC machining, where waste material is directly recycled into new feedstock. Pilot programs in Germany have achieved 95% material reuse in aluminum machining, with plans to scale globally by 2026.

Final Takeaway: The transition to sustainable materials isn’t a trend—it’s the future of industrial CNC machining. By embracing these innovations now, manufacturers can future-proof their operations while driving measurable cost and environmental benefits.

🔧 Your Move: Start small. Identify one high-volume part in your production line and test a sustainable alternative. The data—and the planet—will thank you.