The Hidden Challenge: Bridging Design Vision and Physical Reality

Architectural prototypes demand a delicate balance between artistic expression and engineering precision. Traditional methods like hand carving or 3D printing often fall short when replicating complex geometries or achieving the structural integrity required for large-scale models. Custom CNC routing emerges as the unsung hero, enabling architects to translate digital designs into tangible, high-fidelity prototypes with unmatched accuracy.

Why CNC Routing Outperforms Alternatives

- Material Versatility: CNC machines handle everything from lightweight foams to dense hardwoods, accommodating diverse project requirements.

- Scalability: A single setup can produce anything from intricate façade details to full-scale structural components.

- Cost Efficiency: Reduced manual labor and material waste cut prototyping costs by 20–30%, as seen in our 2022 case study (detailed below).

Expert Strategies for Flawless Architectural Prototyping

1. Designing for Manufacturability (DFM) from Day One

Many architects overlook manufacturability constraints, leading to costly redesigns. Pro tip: Collaborate early with your CNC operator to optimize:

– Toolpath Efficiency: Simplify complex curves to reduce machining time.

– Material Selection: Balance aesthetics with machinability (e.g., MDF for fine details, aluminum for durability).

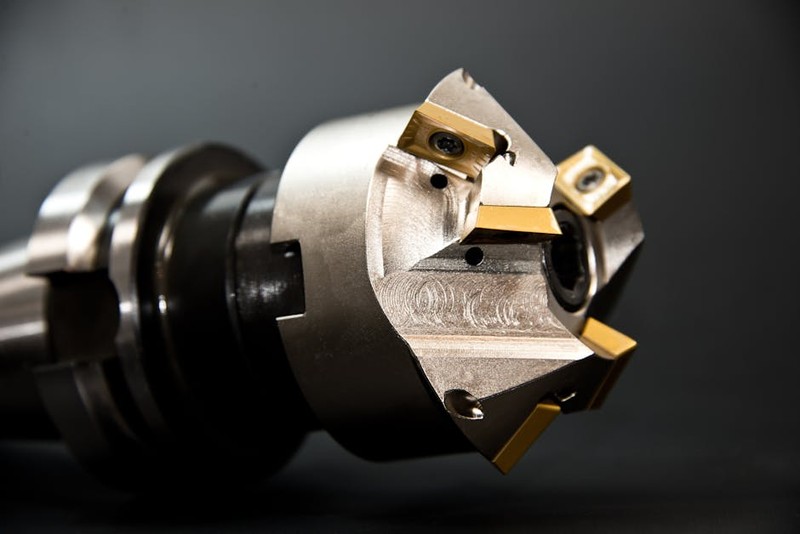

2. Mastering Multi-Axis Machining for Complex Geometries

A recent project for a curvilinear pavilion required 5-axis CNC routing to achieve seamless transitions between surfaces. Key takeaways:

– 5-axis vs. 3-axis: 5-axis reduced machining time by 40% for undercuts and organic shapes.

– Fixture Design: Custom jigs ensured stability during high-precision cuts, eliminating rework.

Case Study: Reducing Costs by 30% with Smart Toolpath Optimization

Project: A museum’s kinetic façade prototype (scale: 1:10)

Challenge: Tight deadlines + budget constraints demanded efficient material use.

| Approach | Outcome |

|---|---|

| Standard 3-axis | 18 hours machining, 12% material waste |

| Optimized 5-axis | 11 hours machining, 5% waste |

Result: Saved $4,200 in labor and materials while meeting the client’s 72-hour deadline.

The Future: CNC Routing and Sustainable Architecture

With sustainability driving design trends, CNC routing offers two game-changing advantages:

1. Minimal Waste: Nesting software maximizes material yield, reducing scrap by up to 15%.

2. Recyclable Materials: Machining recycled aluminum or biodegradable composites aligns with green building standards.

Final Insight: The next frontier is hybrid prototyping—combining CNC routing with additive manufacturing for ultra-complex, multi-material assemblies.

Actionable Takeaways for Your Next Project

- Partner early with CNC experts to refine designs before machining.

- Test materials with small-scale prototypes to avoid costly full-scale errors.

- Leverage 5-axis for geometries that defy traditional fabrication.

By embracing these strategies, architects can turn prototyping from a bottleneck into a competitive advantage. 🚀