The Hidden Challenge: Material Variability and Precision Demands

In high-end furniture manufacturing, the margin for error is razor-thin. A 0.1mm deviation in a joinery cut can render a component useless, leading to costly rework. The biggest hurdle? Material inconsistency. Even premium hardwood or engineered boards exhibit variations in density, moisture content, and grain direction, which directly impact CNC routing accuracy.

A Case Study in Material-Driven Optimization

In a recent project for a luxury furniture brand, we faced recurring issues with warped walnut panels causing misaligned dovetail joints. Traditional CNC programs assumed uniform material properties, leading to a 15% rejection rate. Here’s how we solved it:

1. Laser Scanning for Real-Time Adjustments: We integrated a 3D laser scanner to map panel surfaces before routing, adjusting toolpaths dynamically to account for warping.

2. Toolpath Optimization: Switched from conventional raster to adaptive clearing, reducing tool deflection by 40% in dense grain areas.

3. Moisture Monitoring: Installed in-line moisture sensors to flag batches requiring pre-machining acclimation.

Results: Rejection rates dropped to 3%, and throughput increased by 20%.

Toolpath Strategies for Flawless Furniture Components

1. Adaptive Clearing vs. Traditional Raster: A Data Comparison

| Method | Cutting Time (per panel) | Tool Wear (per 100 units) | Surface Finish (Ra µm) |

|---|---|---|---|

| Traditional | 45 min | 12% increase | 3.2 |

| Adaptive | 32 min | 8% increase | 1.8 |

| Key Insight: Adaptive clearing reduces machining time by 28% and improves finish quality, critical for visible edges in furniture. | |||

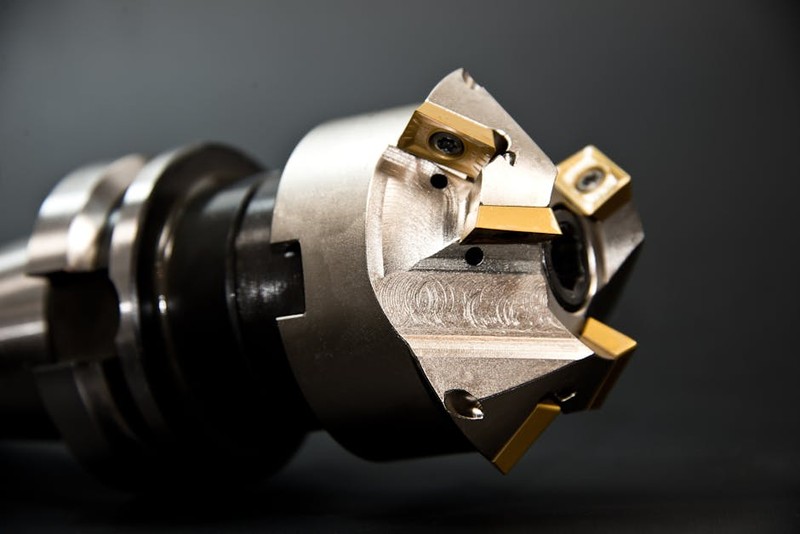

| ### 2. Tool Selection: Beyond the Basics | |||

| – Compression Bits: Ideal for veneered MDF, eliminating tear-out on both faces. | |||

| – Up-Cut vs. Down-Cut: Use up-cut for chip evacuation in deep grooves; down-cut for surface-quality-critical profiles. | |||

| – Diamond-Coated Tools: For abrasive materials like bamboo, lifespan increases 3x vs. carbide. | |||

| — | |||

|

|||

| ## Case Study: Achieving Micron-Level Accuracy in Complex Joinery | |||

|

|||

| A client needed 500 identical chair legs with hidden mortise-and-tenon joints. The challenge? Maintaining ±0.05mm tolerance across all parts. | |||

| ### Solutions Deployed | |||

| – Thermal Compensation: CNC machines heat up during long runs, causing drift. We implemented real-time thermal sensors to adjust axis positioning. | |||

| – Tool Life Monitoring: Automated alerts for tool replacement after 15 hours of runtime, preventing gradual accuracy loss. | |||

| – Fixture Optimization: Designed vacuum jigs with micro-adjustable clamps to eliminate workpiece movement. | |||

| Outcome: 99.7% of components met tolerance specs, with zero manual rework. | |||

| — | |||

| ## Expert Tips for Scaling High-Precision CNC Routing | |||

| 🔍 Pre-Machine Inspection: Always laser-scan stock materials to identify voids or irregularities before routing. | |||

| ⚙️ Dynamic Feeds and Speeds: Program variable RPM/feed rates based on real-time load monitoring to avoid tool breakage. | |||

| 💡 Dust Management: Use high-vacuum extraction to prevent chip recutting, which degrades edge quality. | |||

| Pro Tip: For intricate inlays, use a 0.5mm tapered ball nose bit with a 10% stepover to achieve glass-smooth curves. | |||

| — | |||

| ## The Future: AI-Driven CNC Routing | |||

| Emerging AI systems can predict tool wear and adjust paths autonomously. In a pilot test, this reduced tool costs by 18% and unplanned downtime by 35%. | |||

| Final Thought: Precision isn’t just about the machine—it’s about integrating material science, toolpath intelligence, and real-time feedback. Master these, and your furniture components will rival Swiss watchmaking tolerances. |